5 Description of PLC device

(1) When connected to LX3 series PLC, please refer to LX3 series BD module manual.

(2) When connected to LX5 series PLC, if the firmware version of PLC is lower than 2.051 (excluding 2.051),

or BD module is not configured by host computer, it can be controlled by the following system devices:

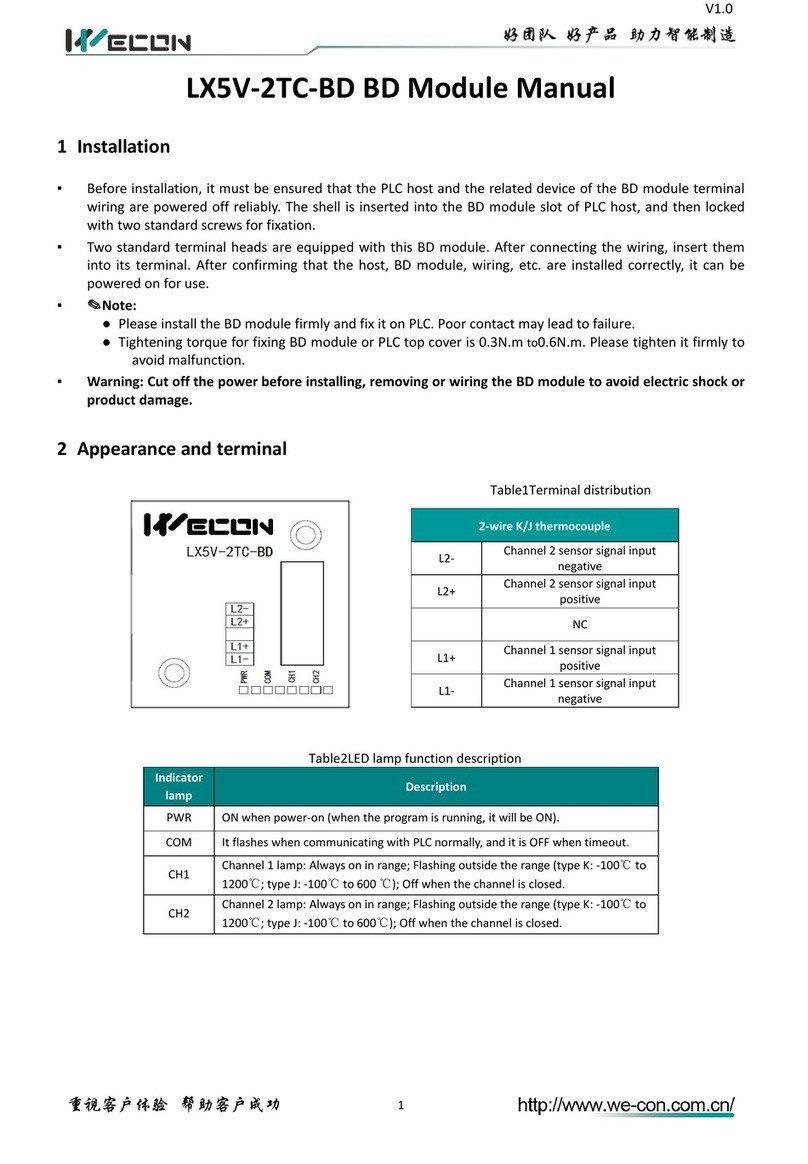

Table3Device allocation

Expansion port 1 description

Expansion port 2 description

CH1 thermal resistance input

channel open flag

OFF: Open

ON: Close

CH1 thermal resistance input channel

open flag

OFF: Open

ON: Close

CH2 thermal resistance input

channel open flag

OFF: Open

ON: Close

CH2 thermal resistance input channel

open flag

OFF: Open

ON: Close

CH1 temperature at 0.1℃unit

(-190℃to 600℃: -1900to6000)

The temperature of CH1 at 0.1°C

(-190℃to 600℃: -1900to6000)

The temperature of CH2 at 0.1°C

(-190℃to 600℃: -1900to6000)

The temperature of CH2 at 0.1°C

(-190℃to 600℃: -1900to6000)

(3) You can select device through I/O mapping to use the configuration function of new BD module. For

details, please refer to "6.1 Parameter configuration".

6 Instructions for use

6.1 Parameter configuration

① Open the host computer software and create a new project, double-click “Project Manager” →

“Extended Function” → "BD Module Configuration" Noteto enter “BD settings” interface;

② Configure the currently connected PLC (take the LX5V-2416 model as an example) and BD module

model on the BD module configuration interface: Select “LX5V-2PTS" in the device bar on the right side

of the BD module configuration interface and double-click to add it to the corresponding slot position of

PLC (slot number 1 or 2, the software will select slot 1 by default, and right-click to move down to slot

2);

③ After adding the BD module to the slot, double-click or right-click to select configuration parameters to

enter LX5V-2PTS-BD configuration parameters interface, as shown in the following figure. Configure

related parameters on this interface.