8

NORTH AMERICA

SECTION 3: COUPLER INSTALLATION

3.2 REMOVE THE EXISTING BUCKET

• Beforeyoutthecouplertothecarriermachineyouhave

to rst remove any existing attachment from the dipper

arm. (Fig 3.2.1)

• Place the bucket or attachment in a safe position on the

ground.

• Undo the pin retention systems holding the dipper pin and

link pin in their position.

• Gentle raise the bucket off the ground and rotate the

cylinder until the weight is off the dipper pin.

• Remove the dipper pin and place in a clean area.

• Lower the bucket to the ground with the bucket curl cylinder

until there is no longer weight on the link pin.

• Remove the link pin and place in a clean place.

3.3 FITTING THE COUPLER (Link Pin)

• Ensurethecouplerissittingonaatsurfaceinthecorrect

orientation.

• Align the dipper arm of the carrier machine with the coupler.

• Position the o-rings for the linkage boss assembly on the

linkageboss(iftted).

• Using the bucket curl cylinder lower the linkage into position

on the rear boss of the coupler (Fig 3.3.1).

• Align the coupler if necessary using a bar or lever.

• Insert the linkage pin through the coupler boss and linkage

boss.

• Alignpinretentionsystemandxlinkagepinintoplace.

• Locatetheo-ringsintothecorrectposition(iftted).

• NOTE – ORIGINAL OEM LINKAGE PIN MUST BE USED.

Page 7

SECTION 3: COUPLER INSTALLATION

3.2 REMOVE THE EXISTING BUCKET

• Before you fit the coupler to the carrier machine you have

to firstly remove any existing attachment from the dipper

arm. (Fig 3.2.1)

Place the bucket or attachment in a safe position on the

ground.

Undo the pin retention systems holding the dipper pin and

link pin in their position.

Gentle raise the bucket off the ground and crowd the

cylinder until the weight is off the dipper pin.

Remove the dipper pin and place in a clean area.

Lower the bucket to the ground with the crowd cylinder

until there is no longer weight on the link pin.

Remove the link pin and place in a clean place

Fig 3.2.1 Remove Bucket

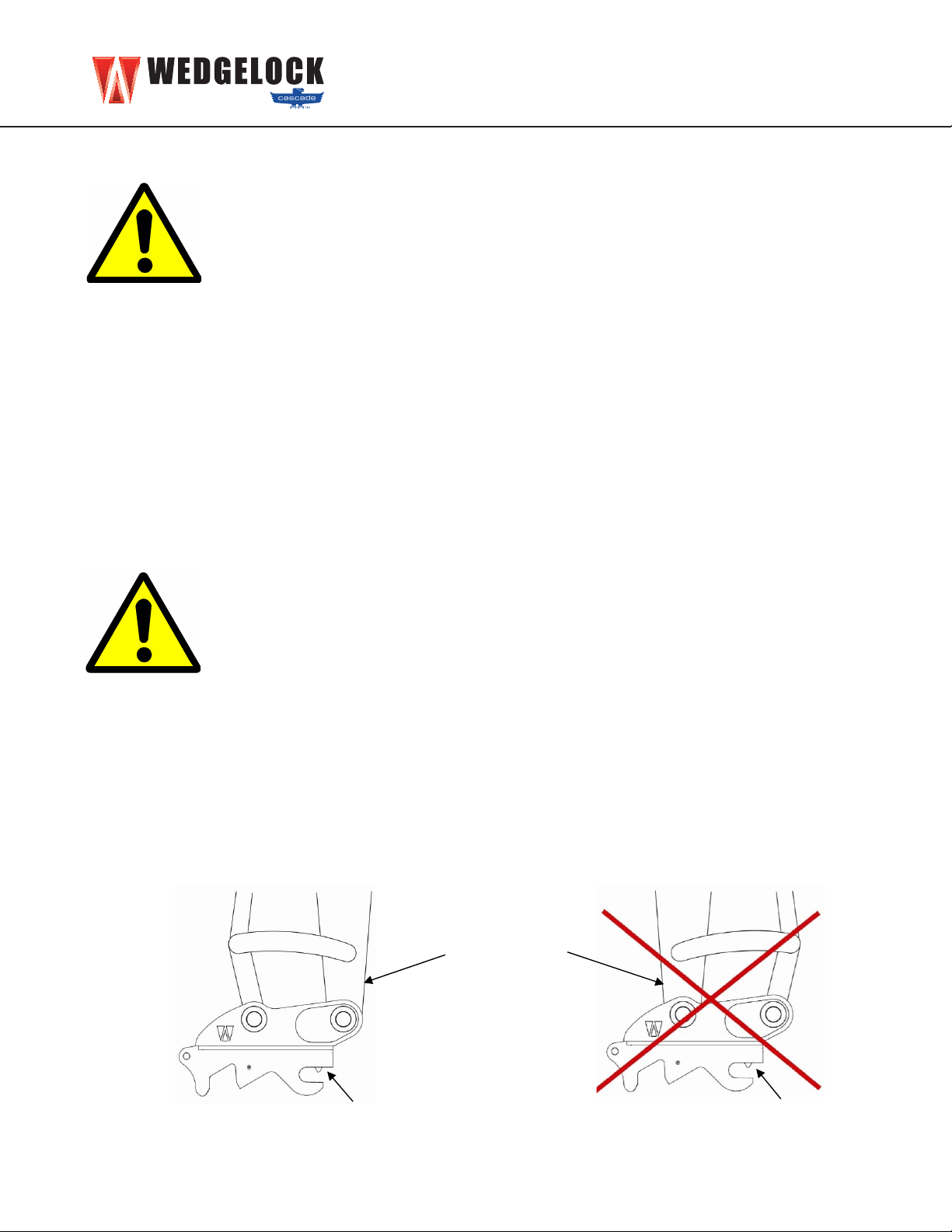

3.3 FITTING THE COUPLER (Link Pin)

• Ensure the coupler is sitting on a flat surface in the correct

orientation.

Align the dipper arm of the carrier machine with the

coupler.

Position the o’rings for the linkage boss assembly on the

linkage boss (if fitted).

Using the crowd cylinder lower the linkage into position on

the rear boss of the coupler (Fig 3.3.1)

Align the coupler if necessary using a bar or lever.

Insert the linkage pin through the coupler boss and

linkage boss.

Align pin retention system and fix linkage pin into place.

Locate the o’rings into the correct position (if fitted).

NOTE – ORIGINAL OEM LINKAGE PIN MUST BE

USED.

Fig 3.3.1 Lower linkage into coupler