`çãéäÉíÉ=háí==j^k=

`çãéäÉíáçå=çÑ=~ëëÉãÄäó=Öêçìéë

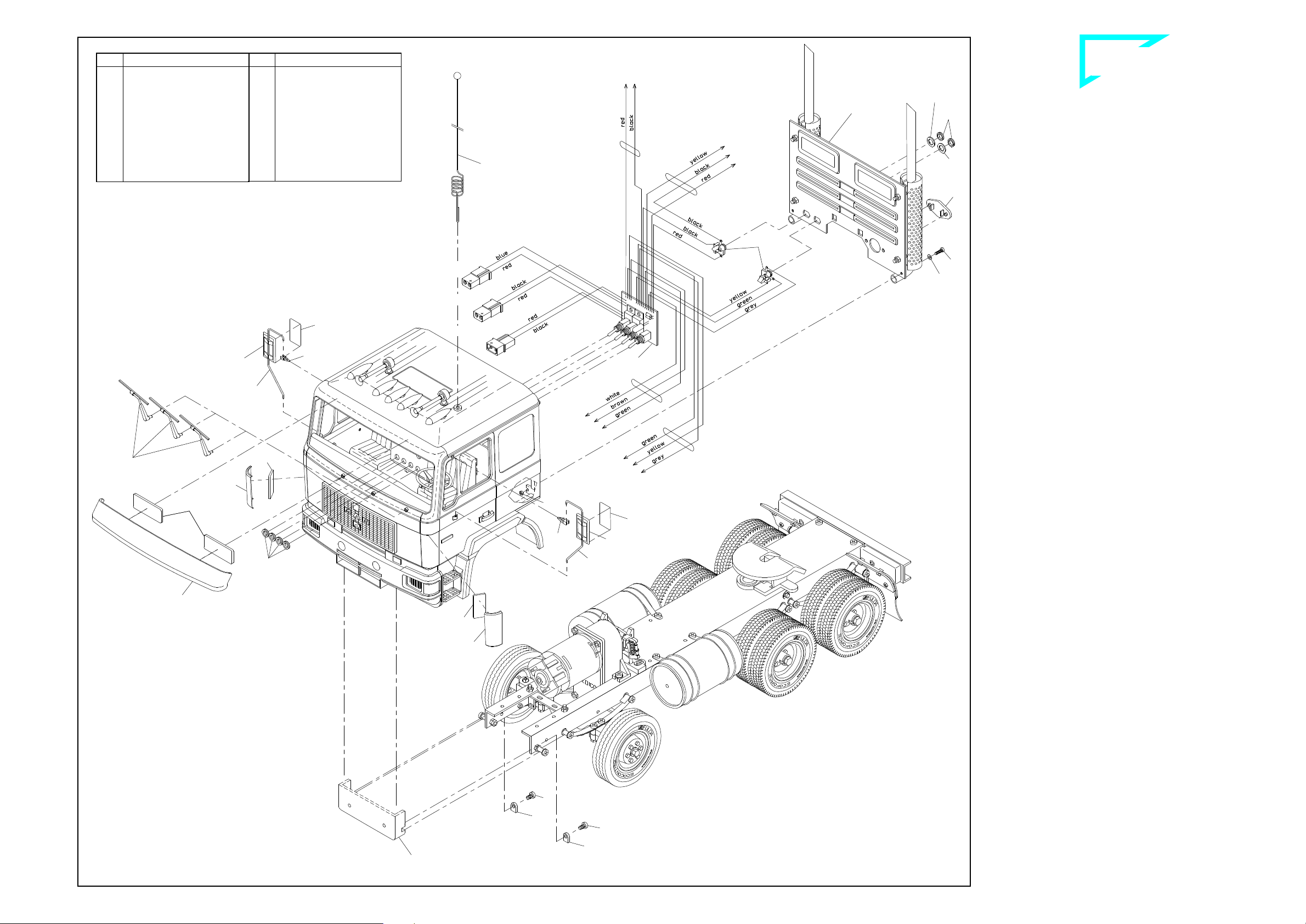

NP qÜÉ=ÉäÉÅíêáÅ~ä=ëóëíÉã=

The wiring diagram shows the cable connections for the individual

electrical components.

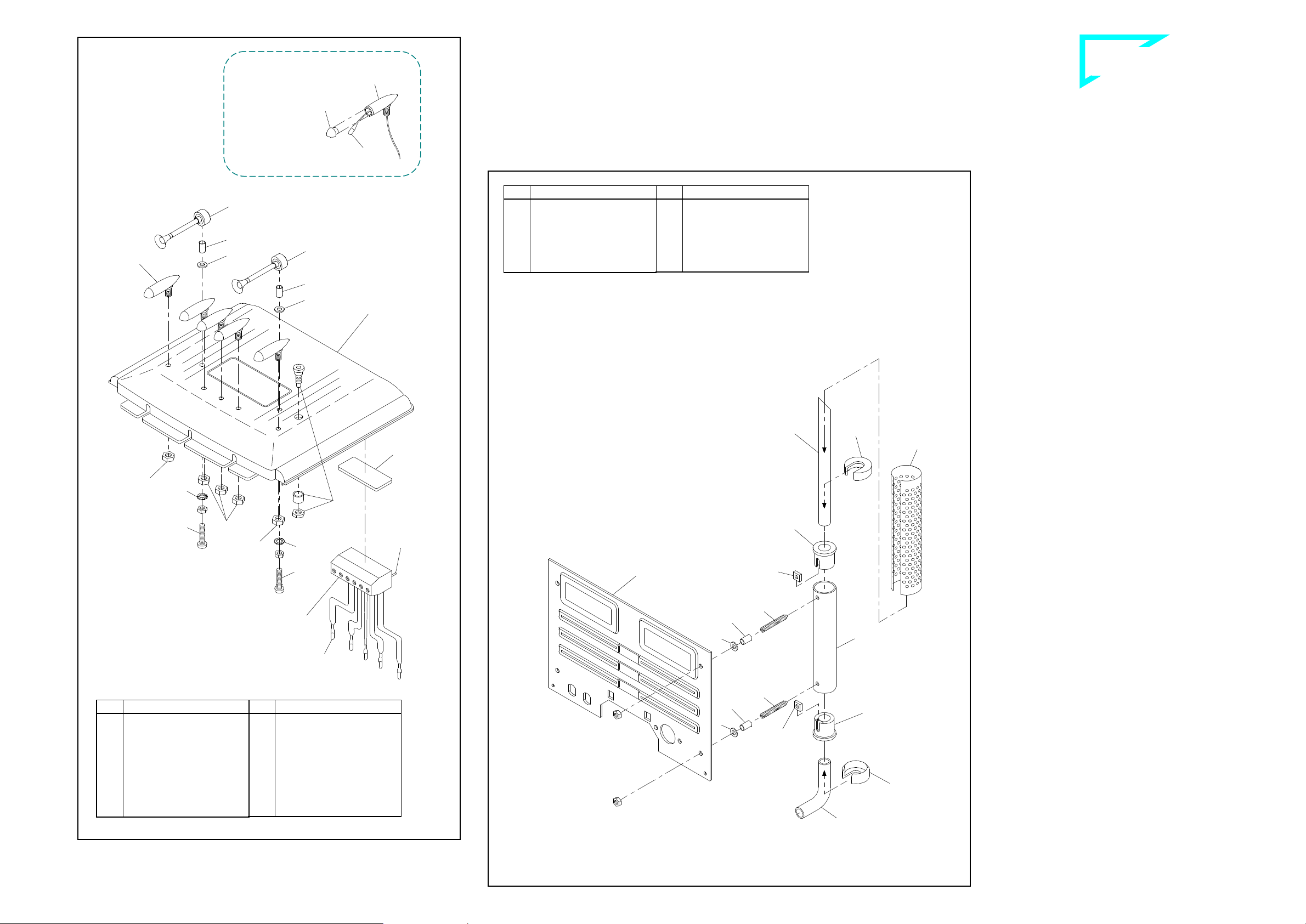

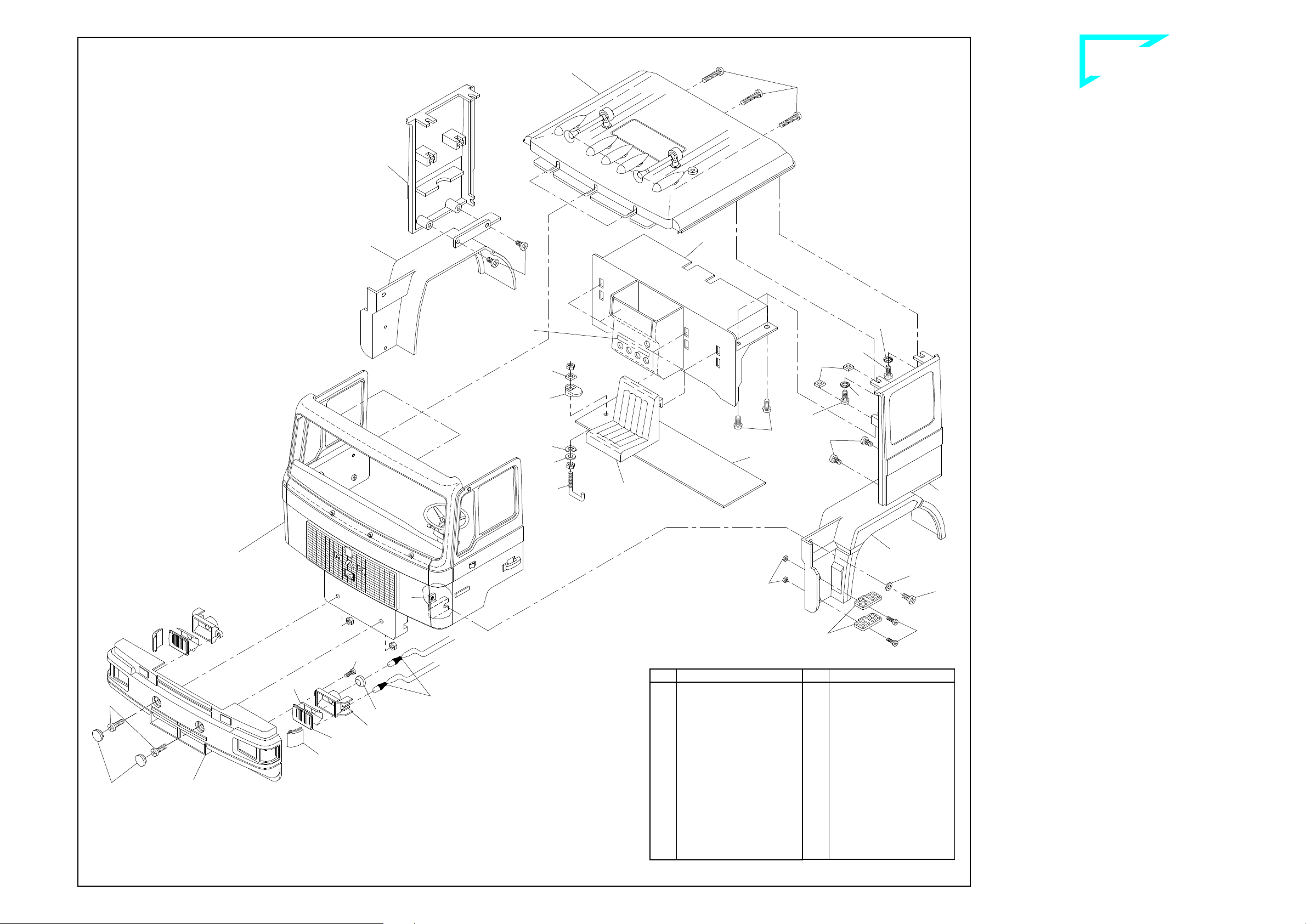

13.1 Mounting the switching panel and lamp PCBs

The switch panel is inserted into the seat rear panel of the cab. First

connect the bulbs and cables and then clip the lamp PCBs in place

at the front and rear in the supports provided for this purpose.

13.2 Information on the bulbs, troubleshooting

All the bulbs are 3-volt bulbs connected in series. This means that

the conductors are not each connected to the supply voltage, as in

an automobile. Instead, the ends are joined one to another to form a

chain and the ends of the chain are attached to the power supply.

Consequently just a single defective bulb will interrupt the entire cir-

cuit and none of the lamps in the chain will light. The best way to lo-

cate the defective bulb is to use a cable to bypass each of the bulbs

in the series, one after the other. When you bypass the defective

bulb, the rest in the chain will light. The reason for using a series

circuit, which may appear to be complicated, is the low power con-

sumption. 3-volt bulbs use far less power than 12-volt bulbs in rela-

tion to their brightness. The power consumed by a chain of up to five

3-volt bulbs is just 0.1 A in the series connection which we use; 12-

volt bulbs, by comparison, would draw 0.3 A.

13.3 Wiring the roof lamps

The bulb leads and the red and black cables from the switch panel are

attached at the screw terminal strip for the roof lamps. Then attach

the terminal strip under the roof as described in Section 3.2.

Be careful when clipping off the solder pins at the terminal strip as

there is a danger of shorts!

13.4 Wiring at the rear lamp PCB

(tail and brake lights, rear blinkers)

The red/black/yellow cable exiting the switch panel for the rear lamps

are routed under the frame and to the rear and connected to the PCB

- marked on the bottom with „H“ for rear - as shown in the illustration.

The green/yellow brake light cable coming from the speed controller

is also to be connected at this PCB. Once the bulb leads have been

attached, the PCB is clipped in place at the support which was previ-

ously affixed with adhesive pads.

Explanation: The green/yellow brake light cable connects the brake

light bulbs to ground when the vehicle is at a standstill. This circuitry

incorporates an element which limits the current to 750 mA and will

disable the circuit in case of an overload or short. Switching off the

supply voltage for about one second will reset this element, provided

that the reason for the malfunction has been corrected.

13.5 Wiring at the front lamp PCB

(headlamps, front blinkers)

The green/yellow/grey cable serving the lamps at the front also exits

from the switch panel and is routed below the frame and to the front

in exactly the same fashion. After connecting to the PCB - marked

on the bottom with „V“ for front - and connecting the bulb leads, the

lamp PCB is clipped in place in the support previously mounted.

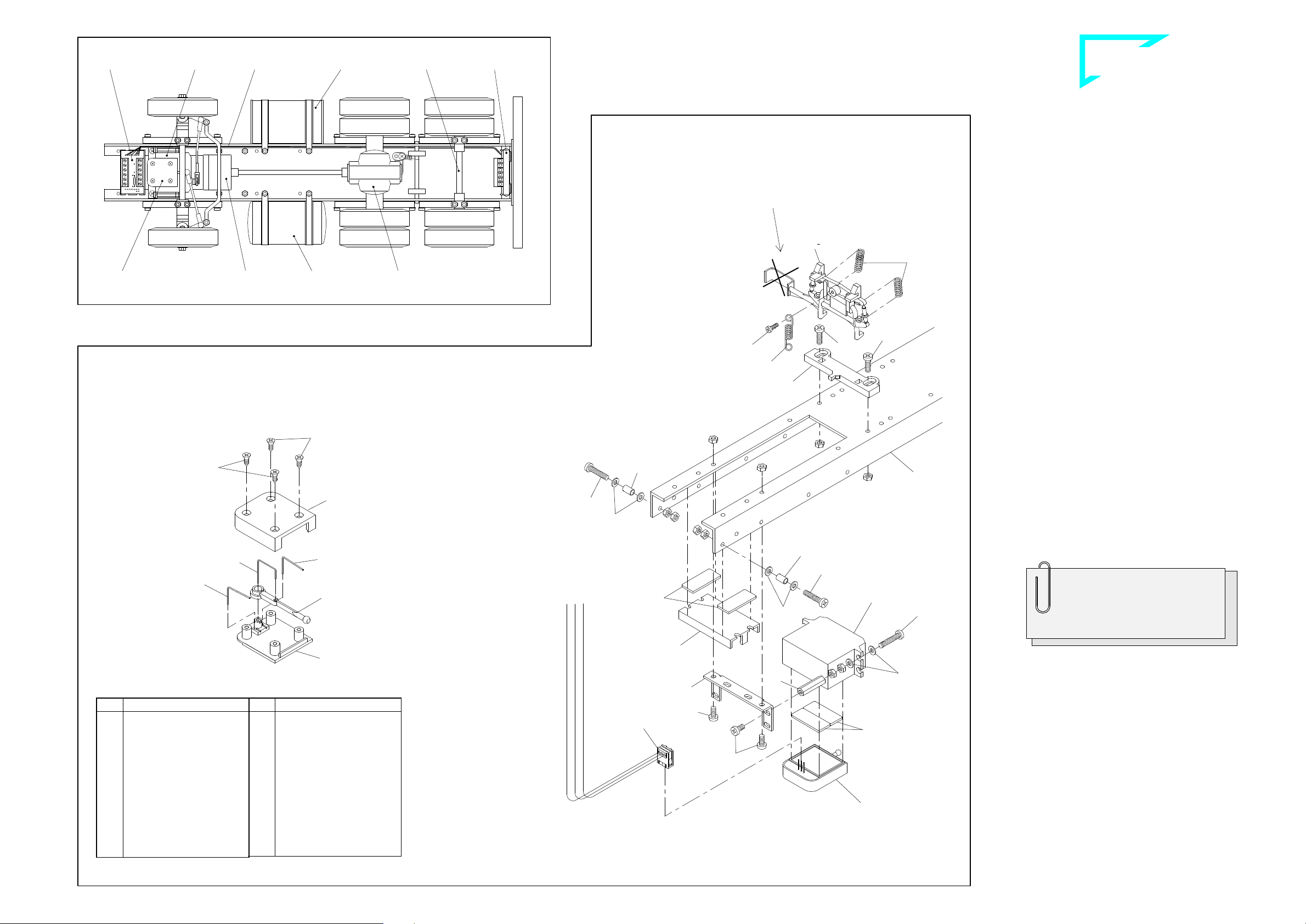

13.6 Wiring the blinker switch

The green/brown/white cable for the blinker switch terminates in a

clamp-type connector (see therefore ill. 13a on page 11). This con-

nector is attached to the blinker switch (if the direction of travel does

not correspond to the blinking, please rotate it through 180°), mounted

beneath the steering servo, already illustrated in ill. 7.

57-e.DOC / K-MAN Page 10

Wiring diagram of the electrical equipment ill. 13

Supplied with the kit:

No. Assembly part

568

Antenna socket

708

Drive motor

929

Clamp-type connector

1580

Speed controller,

round tank short

---

Terminal strip, 6-pole

for roof lamps

---

Blinker switch

---

Drive battery 12 V

---

Charging cable with AMP-plug

---

Set of circuit boards f. complete

chassis with lamp PCBs

---

Switch panel with jack bushes

Not supplied with the kit:

RC receiver

Steering servo

Servo connecting cable

Cable for receiver voltage

Blinker switch

Steering servo

(not incl. in the kit)

white

brown

green

black

red

Brake light

yellow/green

Motor

yellow

yellow

yellow

yellow

red

black

Antenna socket

brown/red/orange

Terminal strip

roof lamps

Clamp type

connector

red

red

black

yellow

green

yellow

grey Head lamps -lh-/-rh-

RECEIVER

(not incl. in the kit)

to the battery box of the

remote control system

or alternative to the

switch panel (ill. 16)

Cable for receiver voltage

(not incl. in the kit)

Speed controller

Antenna cable

black

red

Blinker -lh-

Blinker -rh-

12V Battery

Switch panel

Charging

cable

black

red

blue

Jack bush

Jack bush

Knurled nut

Disc red

Knurled nut

Disc black

grey

green

yellow

Front lamp PCB

Set of circuit boards

for chassis

Blinker -rh-

Blinker -lh-

Rear lamp PCB

black

black

red

yellow

Brake lights

Rear lights

yellow/green

red

black

red

red

B-57-7

Control LED

red/black