`çãéäÉíÉ=háí==^`qolp=

`çãéäÉíáçå=çÑ=~ëëÉãÄäó=Öêç éë

72

71

1

21

57

57

723

655

655

710

709

2

1

25

73

25

709

342

342

341

44 74

46

341

47

908

908

13

13

1390

789

30

3

13

26

13

13

26 13 3

32 33

18

20

27

52

20

2

29

36

55

19

19

2

20

5

18 20 27

52

53

53

29

30

30

36

5

3233 13

3 13 26

3 13

13

26

109 41

42

4

41

41

41

42

434

34

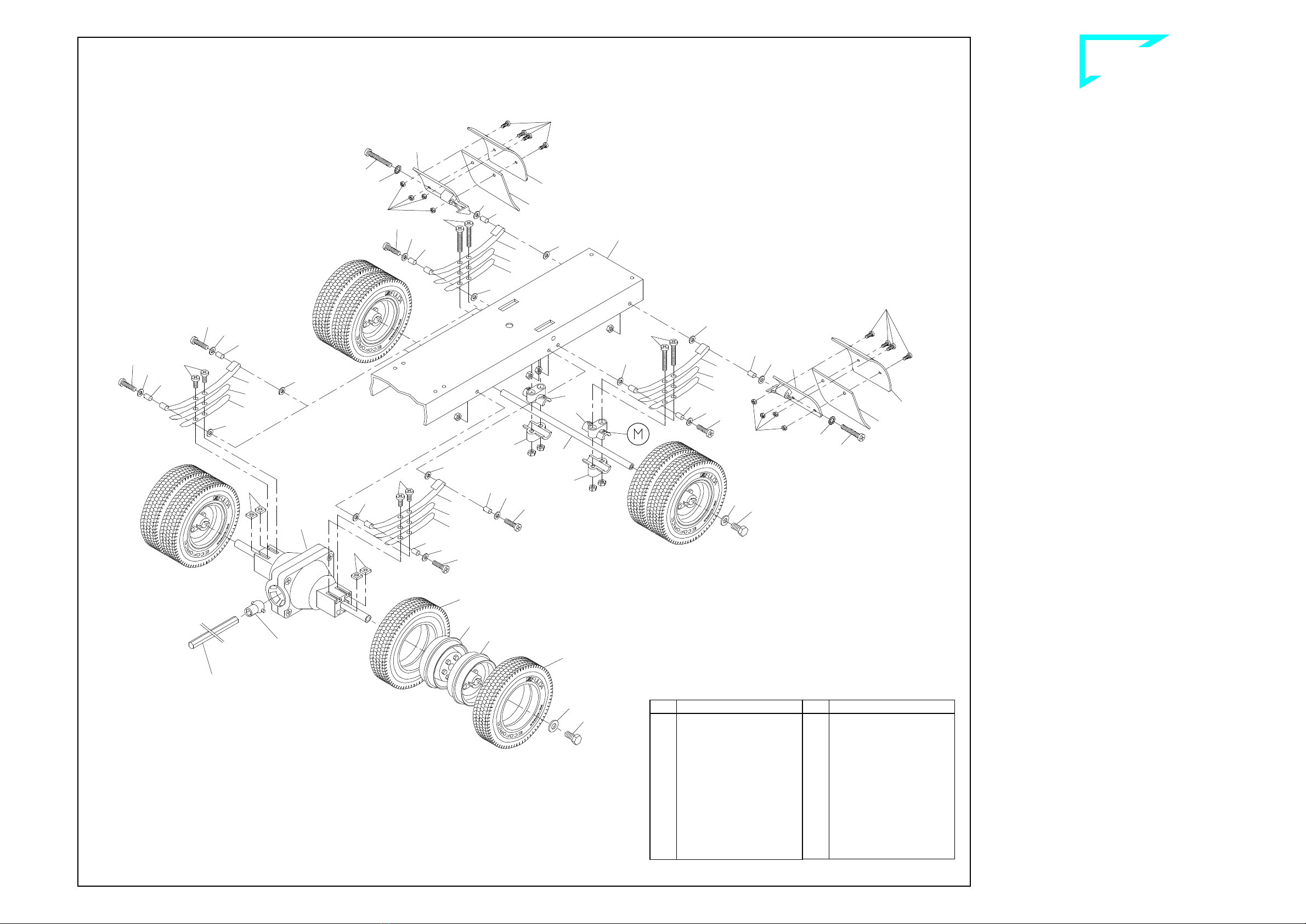

NM `çãéçåÉåíë=~íí~ÅÜÉÇ=íç=íÜÉ==

êÉ~ê=Ñê~ãÉ=ëÉÅíáçå=

10.1 Mounting the fifth-wheel components

Attach the spring 74 to the link lever 44 with a screw 1and M3 nut.

Insert the bar 72 into the opening from above, securing it from below

with the link lever and a tapping screw 21. Mount the fifth-wheel 71

from above, inserting the feet into the slots in the frame. Slide the

shaft 73 through the holes at the side of the frame and the feet of the

fifth-wheel, catching the free end of the spring 74 between the feet

when doing so. The shaft is secured with two retaining washers 25.

Please ensure when attaching the fifth-wheel that the ribbon cable

with the two circuit boards is located between the frame and the

shaft (ill. 8).

10.2 Mounting the rear bumper assembly

First insert the bulbs 713 in the lamp caps 709 as shown in the figure.

Now affix the assembled caps to the rear bumper 47 using one each

screw 57 and M3 nut. From the rear insert the lenses into the bumper:

outwards the blinker lenses 341, inwards the rear light lenses 342.

Attach the frame tail piece 46 underneath the frame using screws 1

and M3 nuts. Then the bumper and carrier plate 710 are set in front

of the frame tail piece and attached with screws 2and M3 nuts.

Take particular care that the bulb cables are not clamped between

the bumper and the frame tail piece; this could cause a short cir-

cuit!

Using two adhesive pads 655, affix the PCB support 723 on the front

surface of the carrier plate, centred and flush with the bottom edge.

NN cêçåí=~ñäÉ=ëÉÅíáçå=

11.1 Mounting the suspension with front axle

First install the screws 3together with washers 13, bushings 26, and

M3 nuts at the rearward holes in the frame, provided for attaching the

springs. Then attach the open ends of the two long spring leaves 32

at the bushings and use an identical set of parts to screw the closed

ends to the front of the frame 45. One nut 19 each is pressed into the

hexagonal depressions at the steering lever 42. Use two screws 5

and M3 nuts to attach to the long spring leafs, previously mounted,

two medium spring leaves 33 and a short spring leaf 34 along with

two half-axle guards 41, into which the front axle 55 and steering

lever 42 have been inserted. Before tightening down the screws 5

ensure that the spring sets are not under tension and can move

freely.

11.2 Mounting the wheels and steering linkage

First mount the standard tyres 53 on the rims 52. Then use screws

18 and one washer 20 each in front of and behind the axle tube 27

located in the hub to bolt the wheels to the steering lever, using the

nut already inserted. To the outer holes on the steering levers fix two

screws 4along with nuts M3. To this unit add now the track rod 1390

using washers 13 and stop nuts 908; do not tighten the stop nuts but

leave the track rod moveable.

With screws 2fix two ball bolts 29 to the inner holes on the steering

levers for the attachment of the steering rods. To a steering rod 36

add one nut 109, fork head 789 and ball socket 30. The steering rod

has to be bent slightly, depending on the size of the servo unit. After-

wards clip this steering rod for the servo linking to the left-hand ball

bolt. For operation of the blinker switch, add to the right-hand ball

bolt another steering rod 36, equipped with two ball sockets 30. Ad-

just the distance between the ball sockets so that the wheels are in

the straight-ahead position when the lever of the blinker switch is in

its neutral setting.

80-e.DOC / K-Actros Page 8

Front axle section ill. 11

Components attached to the rear frame section ill. 10

Qty.

No. Assembly part

10 ---

Nut M3

2 2

Screw M3 x 8

4 3

Screw M3 x 12

2 4

Screw M3 x 16

4 5

Screw M3 x 20

12 13

Washer 3.2

2 18

Hex head screw

M4 x 25

2 19

Nut M4

4 20

Washer 4.3

4 26

Bushing 4 x 0.5 x 7

2 27

Axle tube

2 29

Ball bolt M3

3 30

Ball socket

Qty.

No. Assembly part

2 32

Spring long, “AF“

4 33

Spring medium, “AF“

2 34

Spring short, “AF“

2 36

Steering rod M2 x 50

4 41

Half-axle guard

2 42

Steering lever

2 52

Rim, chromed

2 53

Standard tyre

“Ecocontrol“

1 55

Front axle

1 109

Nut M2

1 789

Fork head

2 908

Stop nut M3

1 1390

Track rod, flat

Frame

B-44-9

Frame

Note!

The kit contains two

additional red lenses

342 for the US chas-

sis version equipped

with red blinkers.

Inserting the bulbs

Bulb for

brake light

Bulb for blinker

Bulb for rear light

B-44-9

Act

709

709

713

Qty.

No. Assembly part

1 73

Shaft for fifthwheel

1 74

Draw spring

2 341

Blinker lens high, orange

4 342

Lens/rear light high, red

2 655

Adhesive pad,

double-sided

2 709

Lamp cap

1 710

Carrier plate for

support PCB

6 713

Bulb 3V

1 723

PCB support, small

Qty.

No. Assembly part

7 ---

Nut M3

3 1

Screw M3 x 6

2 2

Screw M3 x 8

1 21

Tapping screw 2.2 x 4.5

2 25

Retaining washer 3.2

1 44

Link lever

1 46

Frame tail piece

1 47

Bumper, rear

2 57

Screw M3 x 10

1 71

Standard fifthwheel

1 72

Bar for kingpin