52903400000/00/09.2022

2 Safety

2.1 General safety notes

Electricity

– The enclosures of all system components must not be

opened.

– Unauthorised work or modications to the device may

place the operational reliability at risk.

– Installation work and disassembly of the system may

only be carried out if the printer is disconnected from the

mains and the compressed air supply is blocked.

– The system is designed for electricity grids with AC volt-

age of between 100 V and 240 V.

– The system may only be connected to sockets with a

protective earth contact.

– The system may only be connected to devices that con-

duct safety extra-low voltage.

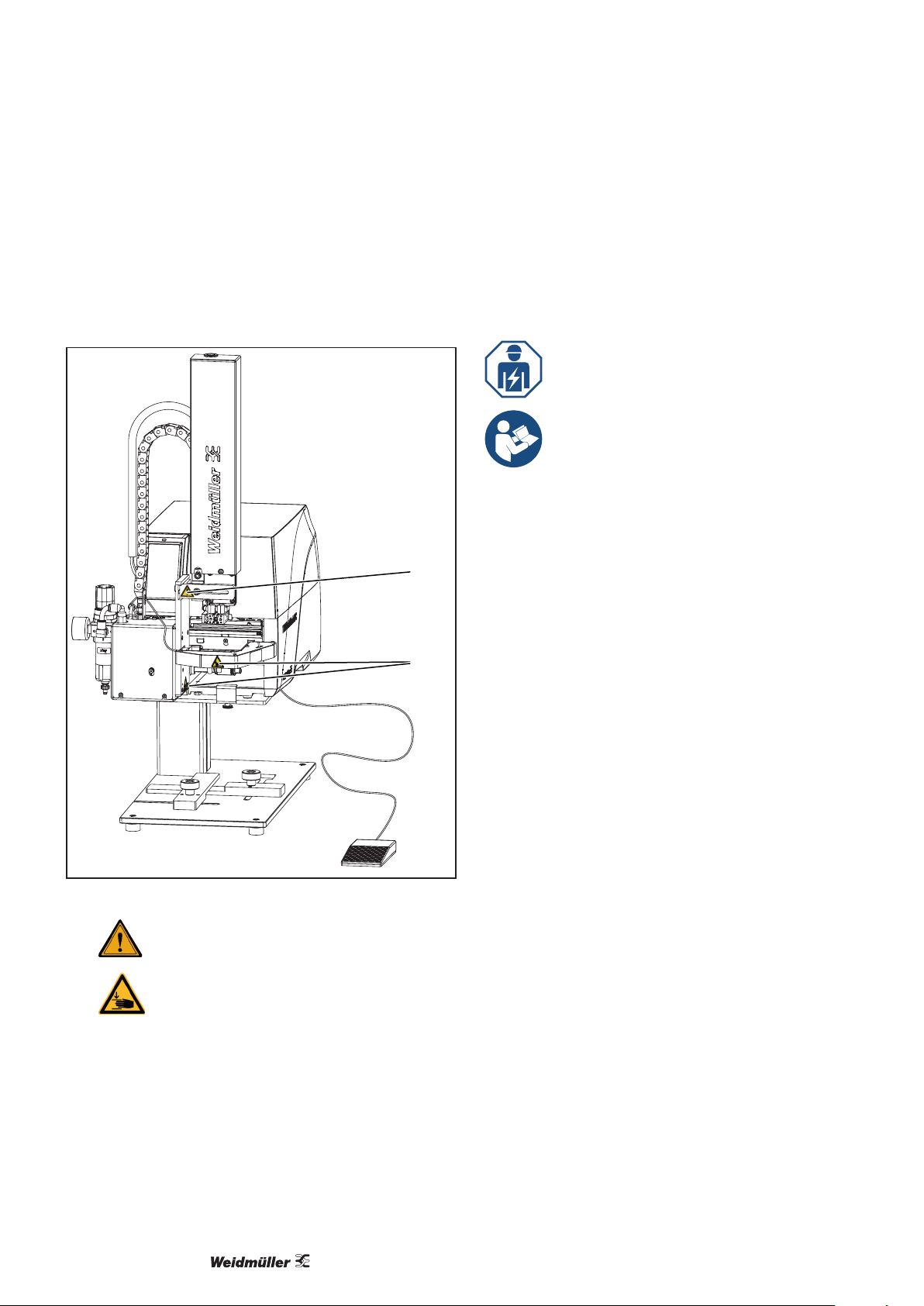

Moving parts

– When operating the applicator, moving parts are acces-

sible when the stamp is moved between the home and

labelling position. Do not reach into this area during op-

eration and keep hair, loose clothing and jewellery and

the like out of this area. The compressed air supply must

be closed when working in this area.

– If the printer is operated with an open cover, make sure

that hair, loose clothing, jewellery and the like do not

come into contact with exposed, rotating parts.

Installation site

– The system is a class A installation. The installation

can cause radio interference in residential areas. In this

case, the operator may be asked to implement adequate

protective measures.

– The system may only be operated in a dry environment

and must not be exposed to moisture (spray water, mist,

etc.).

– The system must not be operated in potentially explo-

sive atmospheres.

– The system must not be operated near high-voltage

lines.

Personnel, activities

– Only carry out the actions described in these instruc-

tions. Additional work may only be carried out by trained

personnel or service technicians.

– Improper intervention in electronic assemblies and their

software can cause faults.

– Service activities must be carried out in a qualied work-

shop that has the necessary expertise and tools to per-

form the necessary work.

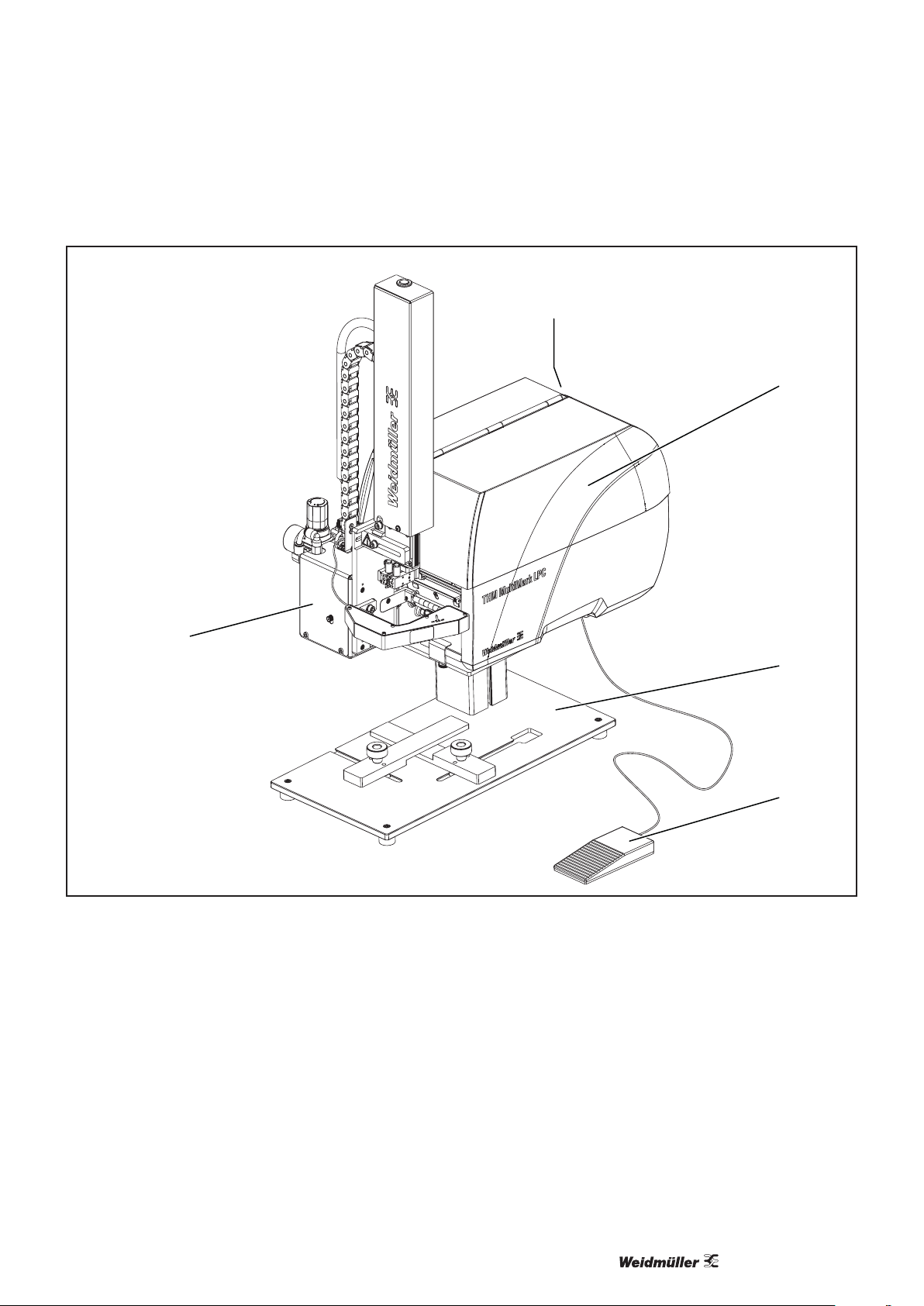

2.2 Intended use

The labelling system is exclusively intended for printing

and applying labels. The system may only be used to pro-

cess materials approved for the labelling system, see the

Weidmüller online catalogue. Any other use or use above

and beyond these instructions is considered incorrect use.

Observance of the documentation, including the mainte-

nance recommendations, is also part of the intended use.

The system may only be operated if it is technically intact.

The system is manufactured based on the state of the art

and the recognised safety rules. However, the use of the

system may pose a danger to life and limb for the user or

third parties and the device and other property may be im-

paired if the safety notes are not observed.