4 2002150000/03/06.2017

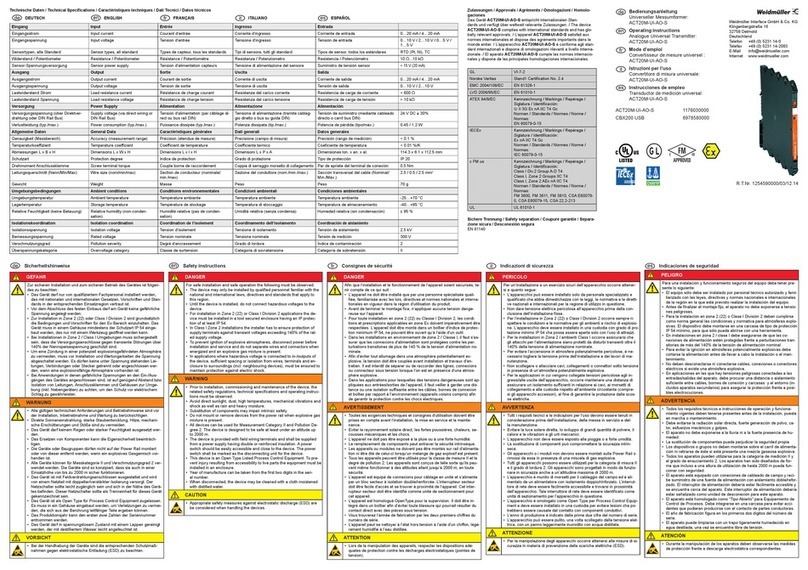

1 Safety

1.1 General safety notications

– Work on the FreeCon product may only

be performed by qualied electricians

with the support of trained persons. As

a result of their professional training

and experience, an electrician is qual-

ied to perform the necessary work

and identify any potential hazards. A

qualied electrician must dimension the

cables.

– Before any work is carried out on the

FreeCon product the power supply

must be switched off and secured

against being switched on again.

– The surface temperature of the

FreeCon products can exceed 70°C

depending on application. To avoid

unintentional touch, install a mechan-

ical barrier or a conspicuous security

advice.

– A power supply with secure isolation

must be used to power the base.

– If faults on a FreeCon product cannot

be rectied using the recommended

measures, the product concerned must

be sent to Weidmüller. Weidmüller

assumes no guarantee if the device is

tampered with!

– During operation, steps must be taken

to ensure that no metallic objects can

enter the air gap between the base and

remote.

1.2 Intended use

The FreeCon Contactless power system

is designed to provide a contactless elec-

tromagnetic connection in an industrial

environment. The housings comply with

IP65 protection. Any other usage is not

permitted and may lead to accidents or

destruction of the device. The observance

of the supplied documentation is part of

the intended use.

1.3 Conformity with EU directives

The product complies with the EMC direc-

tive 2004/108/EC. Weidmüller will provide

the CE Declaration of Conformity upon

request.