Tech. Dok. / WNW 850 02 / 02.2005.A / © MICHAEL WEINIG AG Weinig Tools 1-5

1 Safety .......................................... 1-7

1.1 Intended use ................................ 1-7

1.2 General safety instructions ........... 1-7

1.3 Tools and machine ....................... 1-8

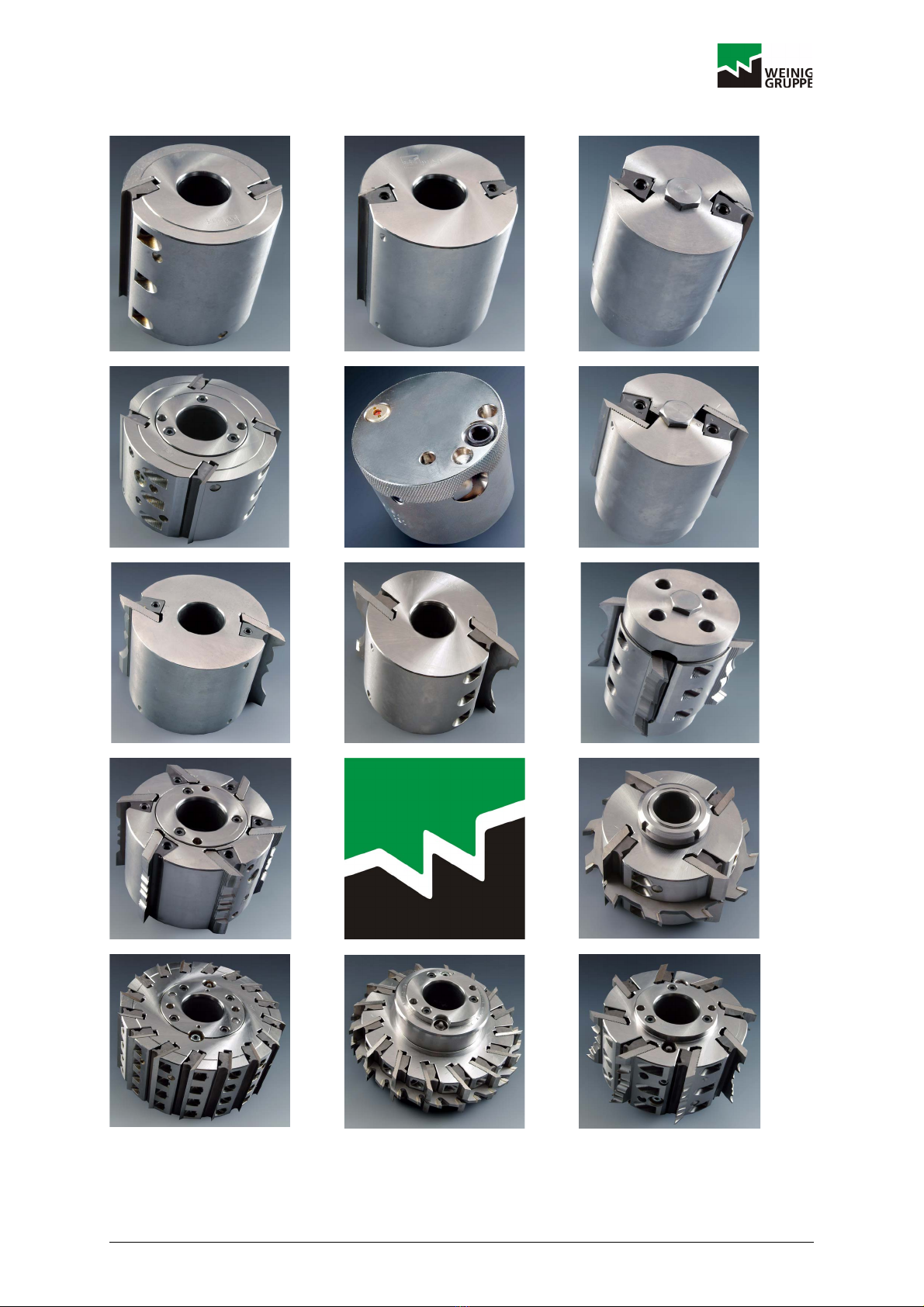

2 PowerLock .................................. 2-1

2.1 Weinig PowerLock 536 ................ 2-2

2.2 Weinig PowerLock 538 ................ 2-5

2.3 Weinig PowerLock 539 .............. 2-10

3 Normal clamping ........................ 3-1

3.1 Hydraulic spindle nut (optional) .... 3-1

3.2 Weinig Centrolock 530 ................. 3-3

3.3 Weinig Centrolock 533 ................. 3-6

3.4 Weinig cutterhead 500 / 510 ...... 3-11

3.5 Weinig profile cutterhead

503 / 513 .................................... 3-15

3.6 Weinig tongue and groove

cutterhead 508 / 518 .................. 3-20

4 Hydraulic clamping .................... 4-1

4.1 Weinig Centrolock 534 ................. 4-1

4.2 Weinig hydro cutterhead

501 / 511

and Rotaplan cutterhead

502 / 512 ...................................... 4-9

4.3 Weinig hydro profile cutterhead

504 / 514 .................................... 4-12

4.4 Weinig hydro cutterhead

508 / 518 .................................... 4-17

Contents