FilterQuick™ FQ4000 FQ80/100/120

Chicken Controller Manual

TABLE OF CONTENTS

CHAPTER 1: FilterQuick™FQ4000 FQ80/100/120 Controller Instructions

1.1 FQ4000 General Information ............................................................................................................1-1

1.2 FQ4000 Button Description and Functions......................................................................................1-1

1.2.1 Navigation Buttons .................................................................................................................1-1

1.2.1.1 Main Menu Button Bar............................................................................................1-1

1.2.1.2 Home Button ............................................................................................................1-1

1.2.1.3 Crew Mode Button...................................................................................................1-2

1.2.1.4 Menus Button...........................................................................................................1-2

1.2.1.5 Recipes Button .........................................................................................................1-2

1.2.1.6 Settings Button.........................................................................................................1-2

1.2.1.7 Service Button ..........................................................................................................1-2

1.2.1.8 Power Button............................................................................................................1-3

1.2.1.9 Language Button......................................................................................................1-3

1.2.1.10 Filter Menu Button ..................................................................................................1-3

1.2.1.11 Temperature Button................................................................................................1-3

1.2.1.12 Menu Button.............................................................................................................1-3

1.2.1.13 Energy Saver Button ................................................................................................1-3

1.2.1.14 Information Statistics Button .................................................................................1-3

1.2.1.15 Escape or Back Button.............................................................................................1-3

1.2.1.16 TPM (Total Polar Materials) OQS (Oil Quality Sensor) Button ............................1-3

1.3 FQ4000 Menu Summary Tree............................................................................................................1-4

1.4 FQ4000 Information Summary Tree.................................................................................................1-5

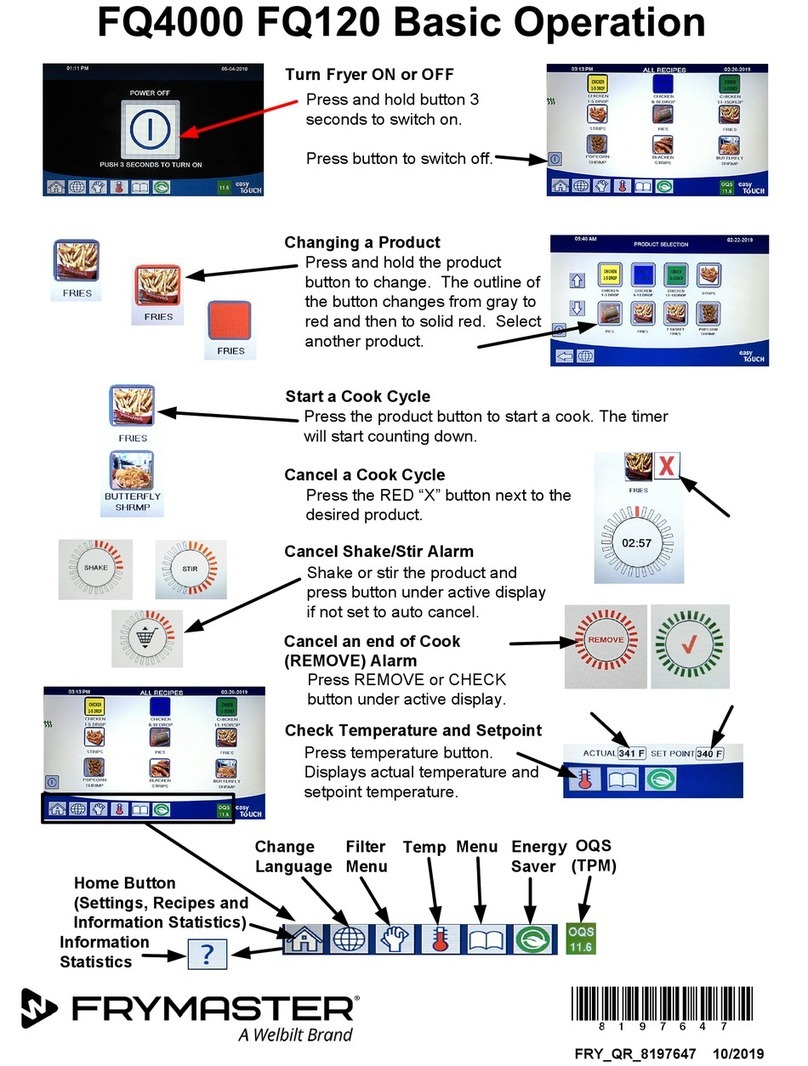

1.5 Basic Operation ...................................................................................................................................1-6

1.6 Cooking .................................................................................................................................................1-7

1.7 Fryer (Service) Setup Programming ..................................................................................................1-8

1.8 Fryer (Manager) Settings Programming ........................................................................................ 1-14

1.9 Adding or Editing Existing Products............................................................................................... 1-25

1.10 Adding or Editing Menus ................................................................................................................. 1-29

1.11 Changing Menus............................................................................................................................... 1-30

1.12 Service Tasks..................................................................................................................................... 1-31

1.12.1 High Limit Test .................................................................................................................... 1-31

1.12.2 Manager Functions............................................................................................................. 1-32

1.12.2.1 E-Log (Error Log) .................................................................................................. 1-32

1.12.2.2 Passcode Setup.................................................................................................... 1-32

1.12.2.3 USB – Menu Operation ....................................................................................... 1-33

1.13 Information Statistics....................................................................................................................... 1-34

1.13.1 Report Card Statistics......................................................................................................... 1-34

1.13.2 Oil Statistics ......................................................................................................................... 1-35

1.13.3 Life Statistics........................................................................................................................ 1-36

1.13.4 Usage Statistics ................................................................................................................... 1-36

1.13.5 Recovery Time...................................................................................................................... 1-37

1.13.6 Filter Statistics ...................................................................................................................... 1-37

1.13.7 Software Version ................................................................................................................. 1-38