Page 7of 12

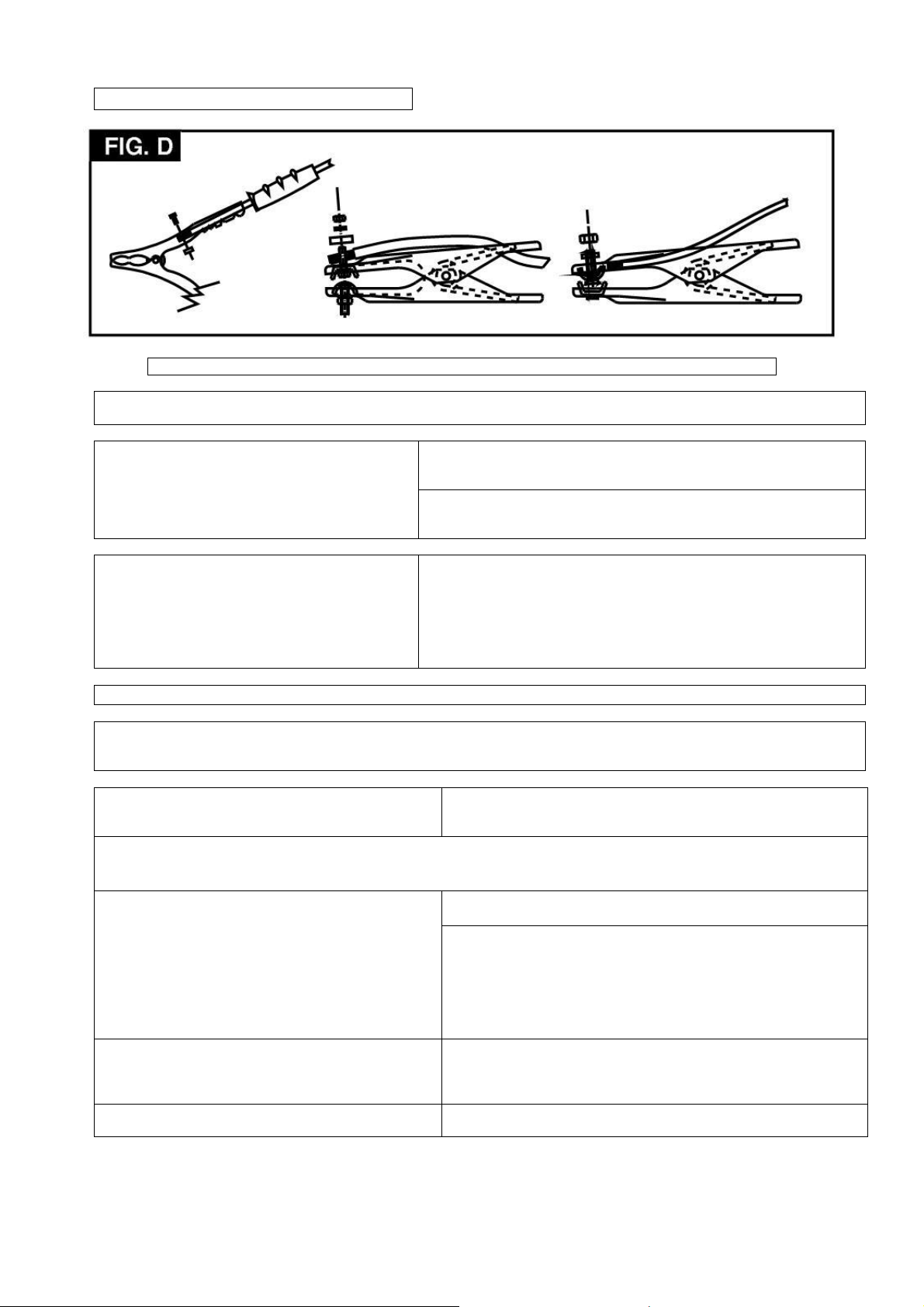

ASSEMBLING THE RETURN CABLE-CLAMP

WARNING! POSITION THE WELDING MACHINE ON A FLAT SURFACE WITH SUFFICIENT CARRYING CAPACITY

FOR ITS WEIGHT, TO PREVENT IT FROM TIPPING OR MOVING HAZARDOUSLY.

Before making any electrical connection, make sure the rating data of

the welding machine corresponds to the mains voltage and frequency

available at the place of installation.

CONNECTION TO THE MAIN POWER

SUPPLY:

The welding machine should only be connected to a power supply

system with the power cable connected to earth.

PLUG AND OUTLET.

(FOR WELDING MACHINES WITHOUT A

PLUG):

Connect a normalised plug (2P + E) having sufficient capacity for the

power cable and prepare a mains outlet fitted with fuses or an

automatic circuit-breaker; the special earth terminal should be

connected to the earth conductor (yellow-green) of the power supply.

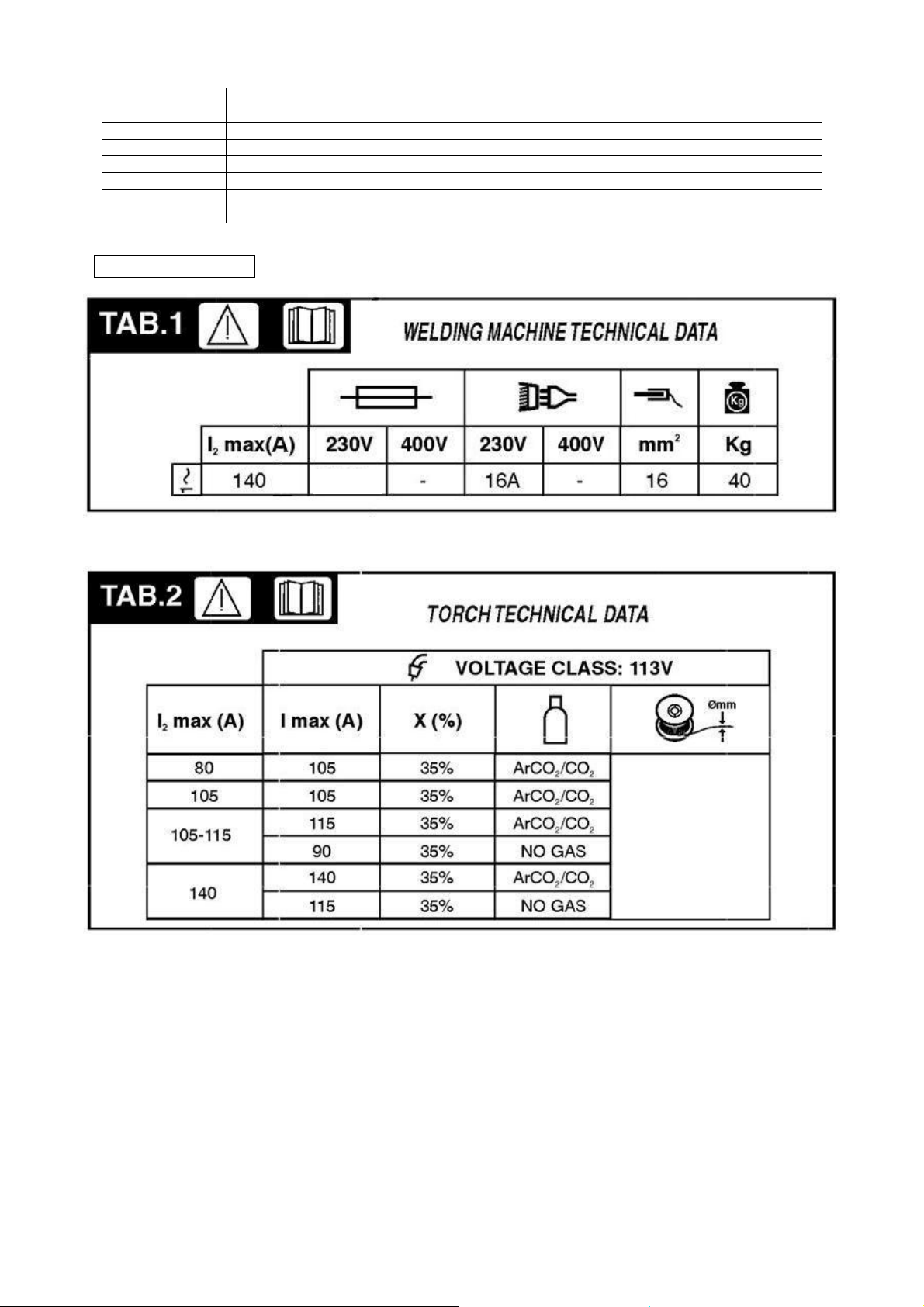

TAB.1 shows the recommended delayed fuse size in amps, chosen

according to the max nominal current supplied by the welding

machine, and the nominal voltage of the mains power supply.

Reassemble the panel carefully using the appropriate screws.

WARNING!

Failure to observe the above rules will make the (Class 1) safety system installed by the manufacturer ineffective

with consequent serious risks to persons (e.g. electric shock) and objects (e.g. fire).

CONNECTION OF THE WELDING CABLES:

Table 1 (TAB. 1) gives the recommended values for the welding

cables depending on the maximum current supplied by the

WARNING! BEFORE MAKING CONNECTIONS MAKE SURE THE WELDING MACHINE IS SWITCHED OFF AND

DISCONNECTED FROM THE POWER SUPPLY OUTLET.

- A gas bottle can be loaded on the welding machine bottle

support frame.

CONNECTION TO THE GAS BOTTLE:

- Screw the pressure reducing valve on to the gas bottle valve,

inserting the appropriate adapter for argon or an argon/C02

mixture.

- Connect the gas inlet pipe to the pressure-reducing valve and

tighten the band supplied.

- Loosen the pressure adjustment knob nut on the pressure-

reducing valve before opening the bottle valve.

CONNECTING THE WELDING CURRENT

RETURN CABLE:

- This is connected to the piece being welded or to the metal

bench supporting it, as close as possible to the join being

made. This cable is connected to the terminal with the symbol

(-).

CONNECTING THE TORCH: - Prepare the wire for loading by dismantling the nozzles and

the welding tip to ease its exit.

None of the welding machines described in this manual are equipped with a lifting device.