INTRODUCTION

IOM-040 Page 4 of 10

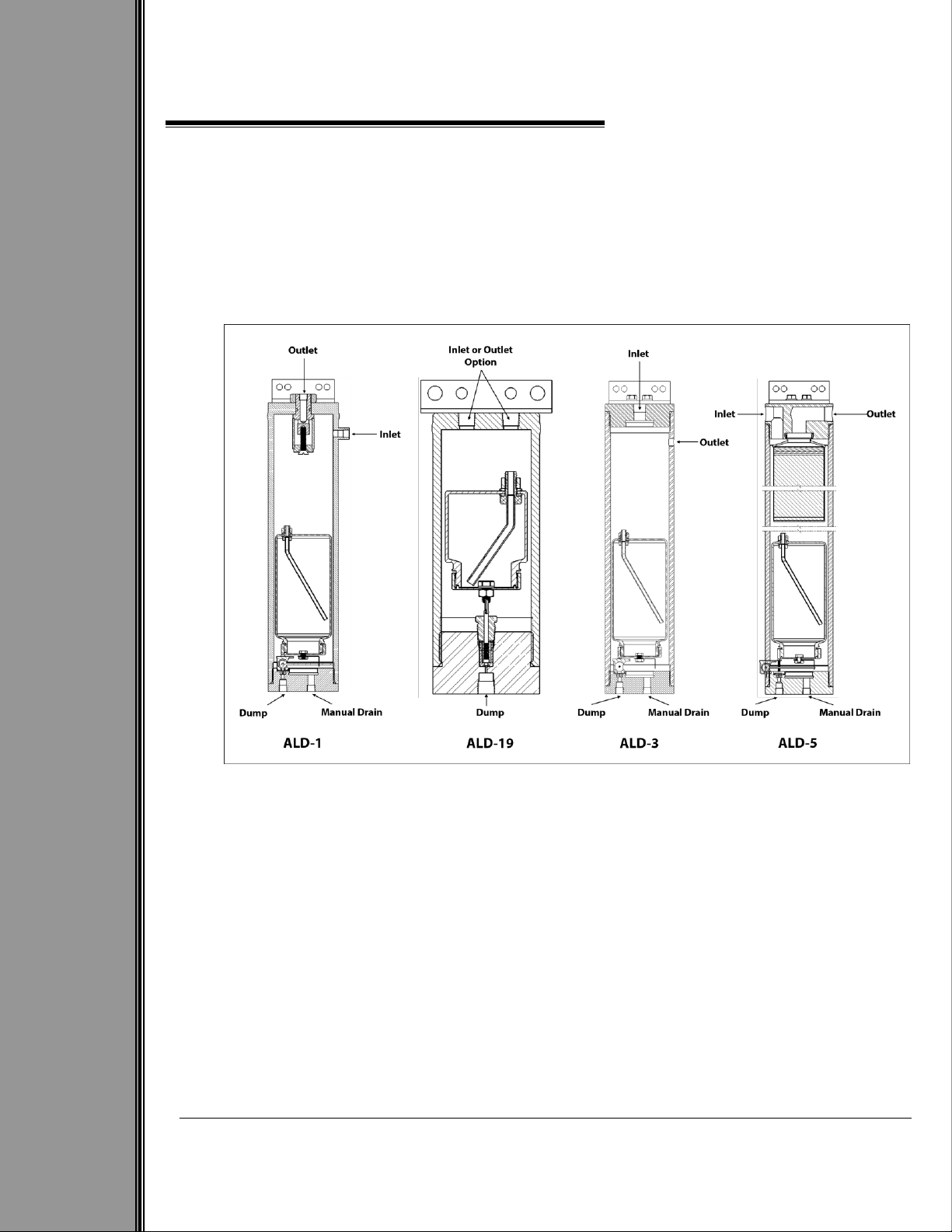

ALD-1, ALD-3, ALD-5, ALD-19

Rev: E

Last updated: 6/30/2023

1 GENERAL

1.1 Introduction

We appreciate your business and your choice of Welker products. The installation, operation, and

maintenance liability for this product becomes that of the purchaser at the time of receipt. Reading the

applicable Installation, Operation, and Maintenance (IOM) Manual prior to installation and operation of

this equipment is required for a full understanding of its application and performance prior to use. If you

have any questions, please call 1-800-776-7267 in the USA or 1-281-491-2331.

The following procedures have been written for use with standard Welker parts and equipment.

Assemblies that have been modified may have additional requirements and specifications that are not

listed in this manual.

Notes, Warnings, and Cautions

Notes emphasize information or set it off from the surrounding text.

Caution messages appear before procedures that, if not observed, could result in

damage to equipment.

Warnings alert users to a specific procedure or practice that, if not followed

correctly, could cause personal injury.

1.2 Product Description

The Welker Automatic Liquid Dump is designed for use in systems where it is necessary to filter

entrained liquids from a process gas. A steady pressure is maintained from the supply source to the

instrumentation connected to the unit. As product enters the device, any free liquids are dropped to a

float at the bottom of the dump. A downcomer is installed inside the float, and as liquids fill the device,

the downcomer itself will begin to float. The downcomer is connected to the dump port, and eventually,

the buoyancy of the float will cause the downcomer to lift. When the downcomer lifts, it will open the

dump port, allowing the liquids to be drained.

The ALD-1 incorporates a coalescing device for product supply that is high in aerosols. The device will

coalesce the aerosols into liquid droplets, which will then drop around the float.