SPECIFICATIONS

IOM-011 Page 4 of 20

CP2G, CP5G, CP35G

Rev: F

Last updated: 7/9/2018

1.2 D

ESCRIPTION OF

P

RODUCT

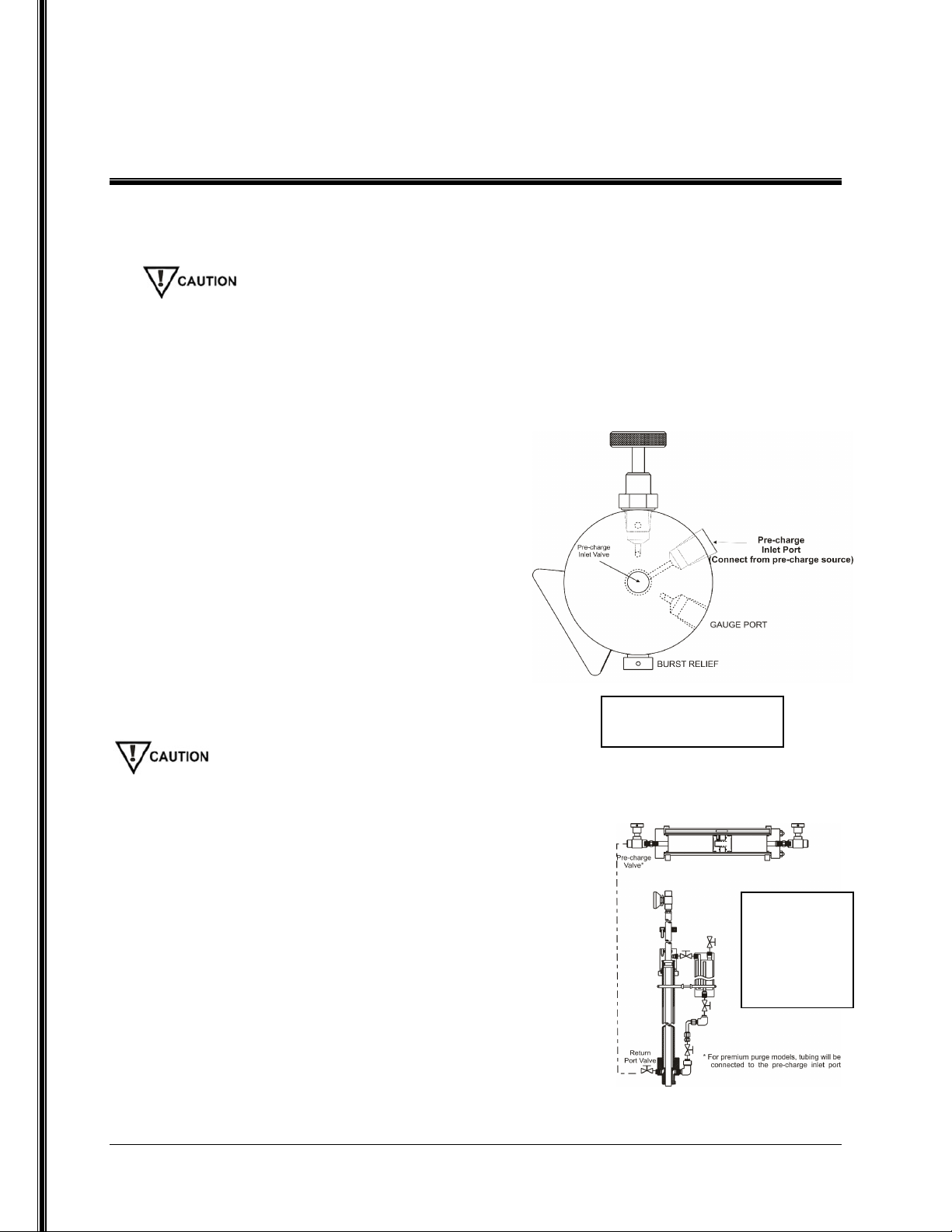

The Constant Pressure Sample

Cylinder is designed for use in

systems where it is necessary to

extract and isolate accurate

product samples by maintaining

a steady pressure from the

pipeline to the cylinder. The

cylinders are equipped with a

magnetic indicator and a

graduated scale set to specify

the capacity of the device.

During continuous sampling,

when the magnetic indicator

reaches the 80% mark, all

sampling should be stopped. A

pneumatic supply pre-charges

the cylinder with pressure to

correspond with pipeline pressure. Pre-charging allows the sample to be transferred to the

cylinder without taking a pressure drop. An internal piston in the cylinder helps to purge

out air and contaminants prior to taking the sample by displacement.

During the purge process, the piston is pushed to the end of the cylinder, also preventing

any other possible contaminants from entering. Burst discs and gauges are also included

on each end cap of the device. In the event that the cylinder is overpressurized, these

discs will rupture, relieving excess pressure from the cylinder. CP-2 Premium Purge

model cylinders have valves built into the pre-charge and product end cap ports. They are

also included with product purge and pre-charge purge valves.

Adjustable relief valve (optional)

The adjustable relief valve functions as a safety device for the unit.

During continuous sampling and transportation of the cylinder, the

relief valve assures that the device maintains a constant pressure

and does not exceed maximum allowable pressure. The valve will

relieve any pressure that exceeds the set pressure.

Figure 2

Figure 1