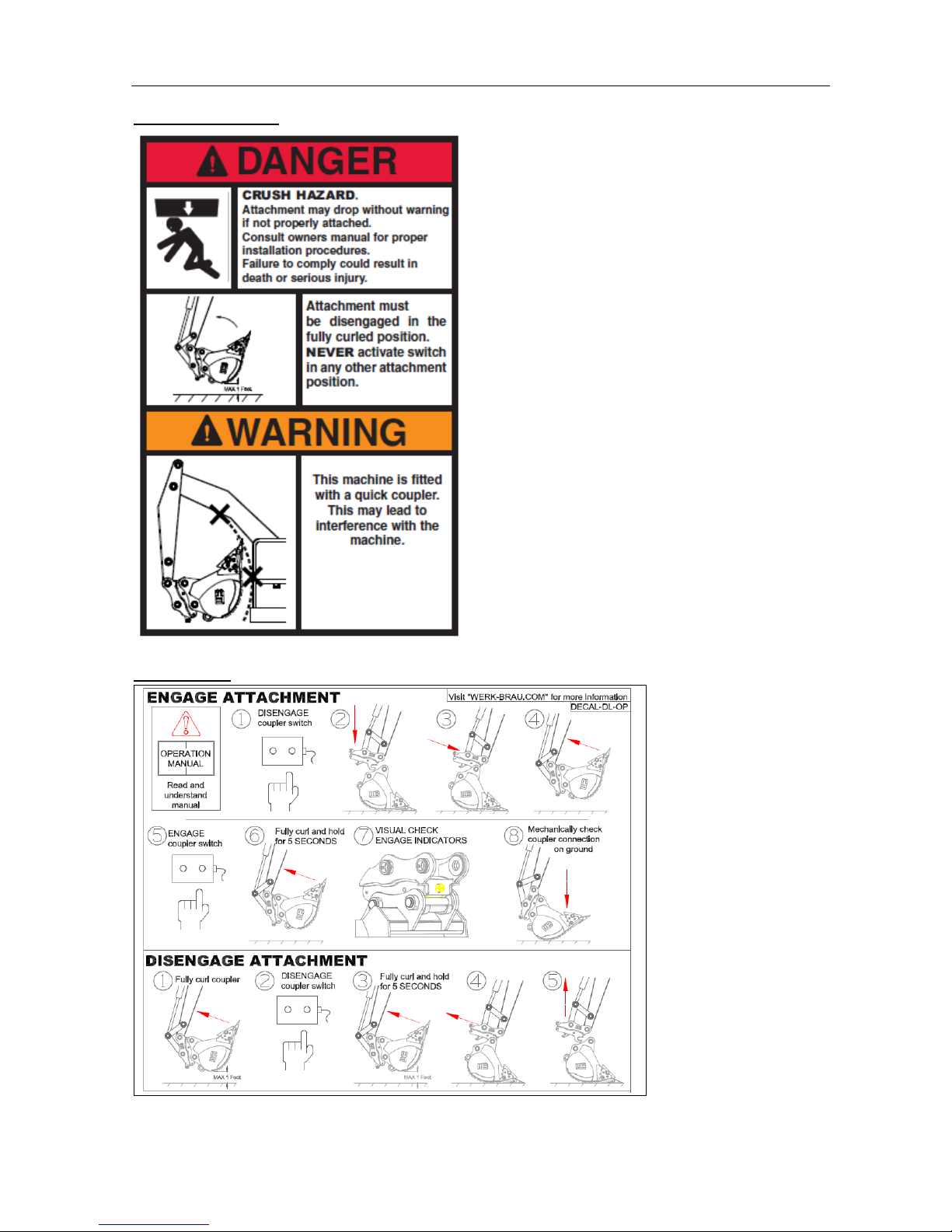

IMPORTANT SAFETY INFORMATION

D - L o c k M a n u a l R e v E . p d f P a g e | 6

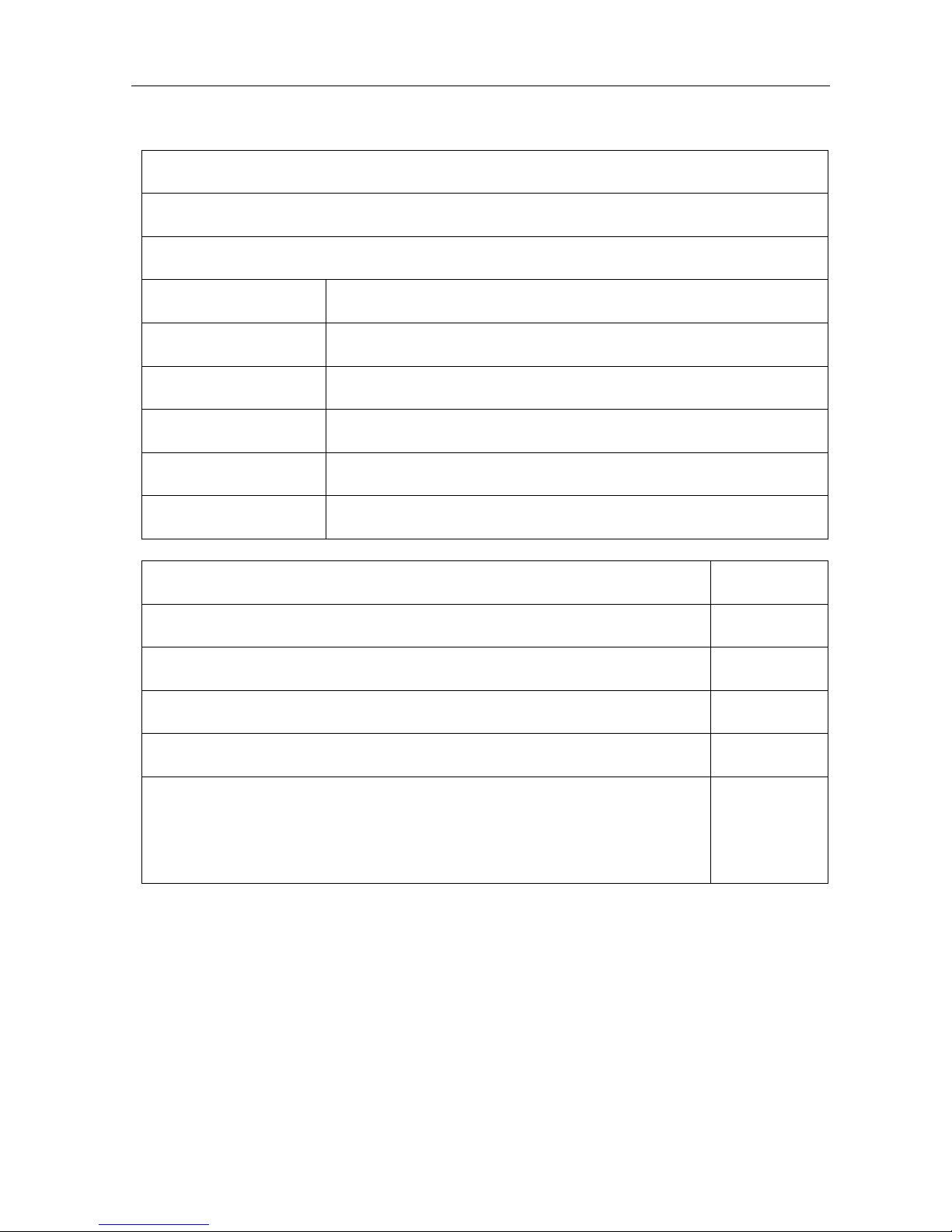

The D-Lock range of Quick Hitch Couplers comply to AS4772-2008 standard for Earthmoving machinery –Quick

hitches (Couplers) for excavators and backhoe loaders AS4772-2008 Clause 2.1.4

Remember that on any job, YOU are the key to safety. Good safe practices not only protect the people around you;

they are also your own best protection. Study this section and any relevant manufacturer’s operation manuals

covering your equipment. Read all warning and caution instructions.

1. This manual must be READ and UNDERSTOOD before any installation and operation work begins. A copy must be

kept in the operator’s cabin for ongoing use.

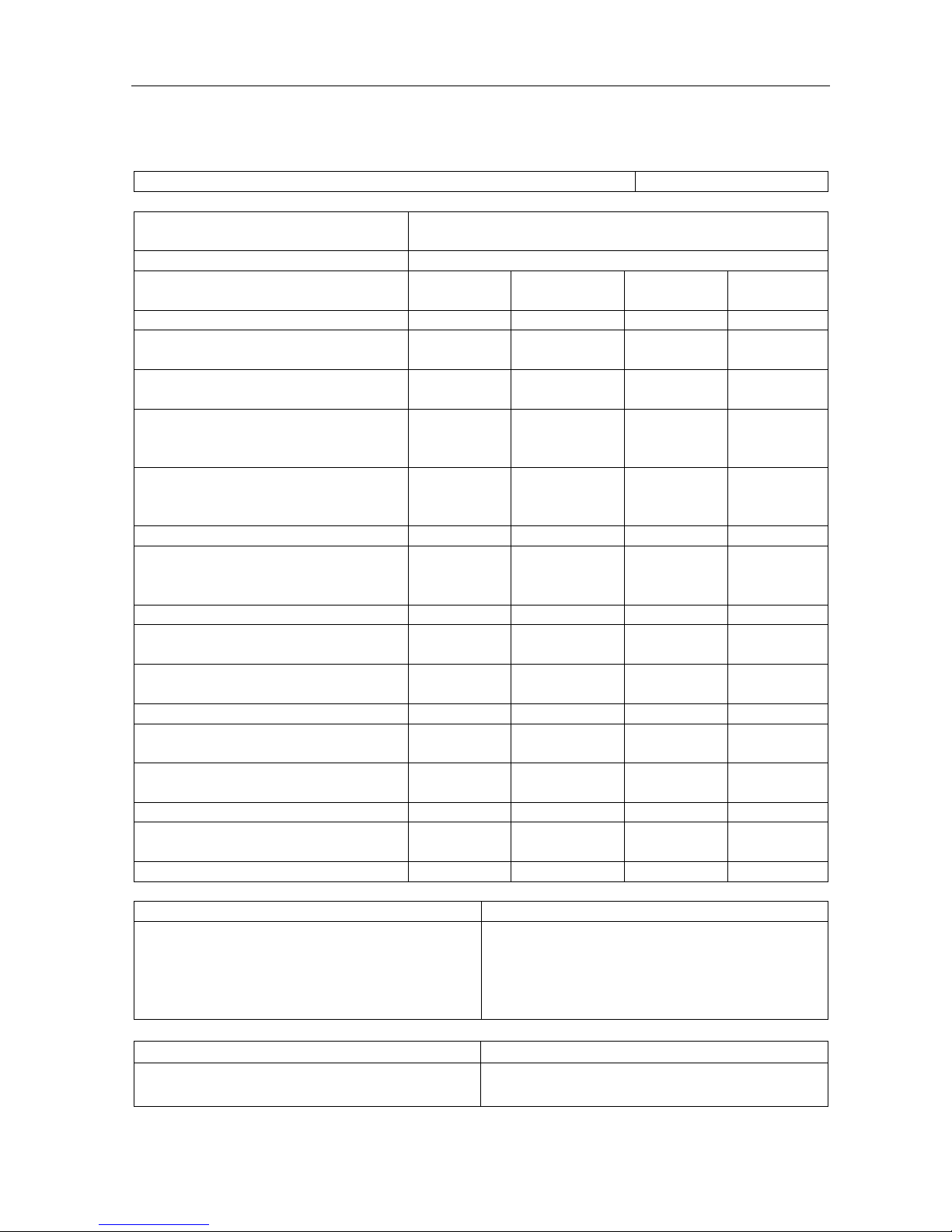

2. Operators should note that the use of a quick coupler may affect the machine's breakout force and balance and may

result in attachments being able to come into contact with the boom set and or operator’s cabin.

3. Operators should note that the weight of the coupler is stamped on the ID Plate and this must be taken into account

which calculating the machine's lifting capacity.

4. Werk-Brau Engineered Attachments Couplers are designed for use with Werk-Brau Approved attachments only.

Approval must be obtained for use with non Werk-Brau attachments.

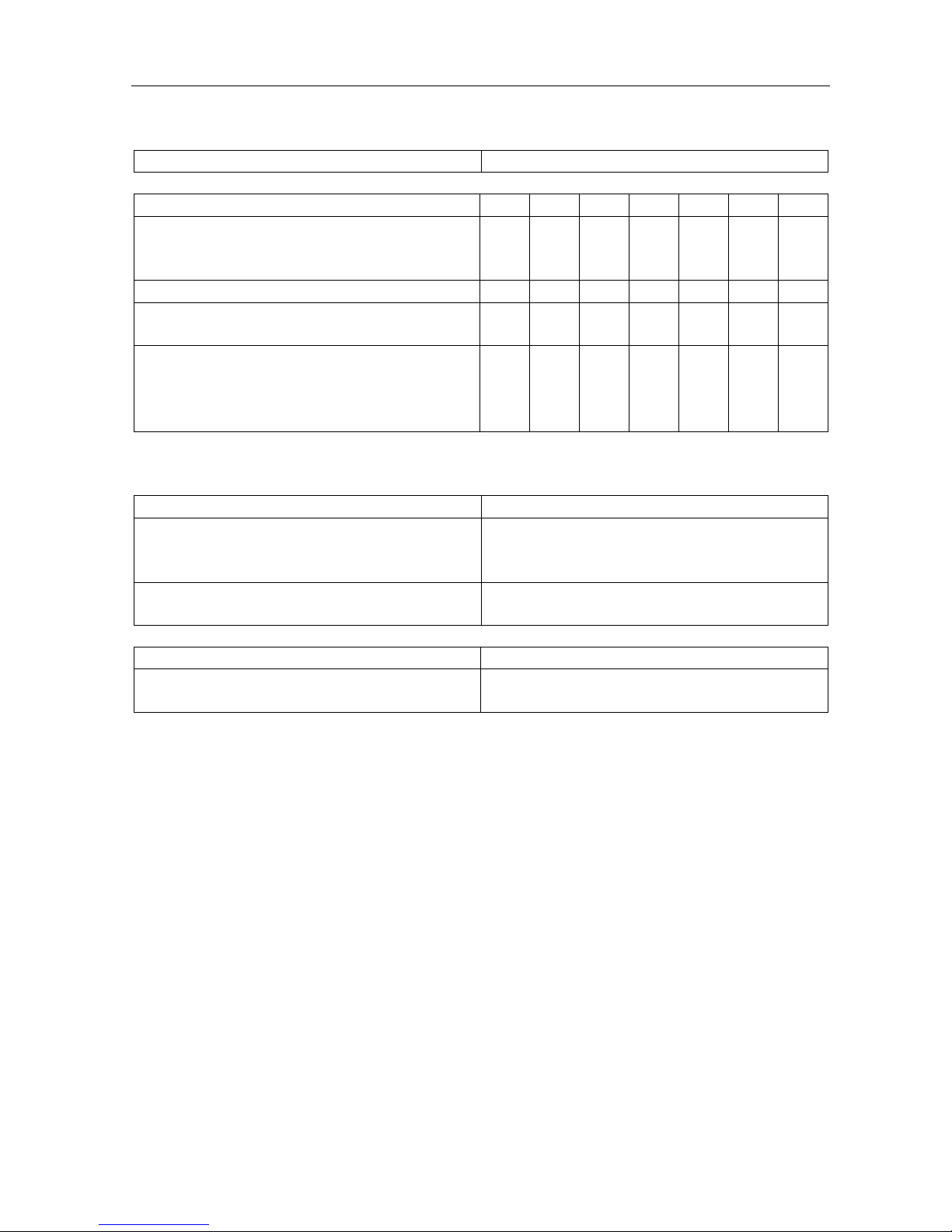

5. All D-lock couplers must be connected and installed in full compliance with this manual. Any variations may cause the

coupler to operate in an unsafe manner and/or void the warranty.

6. Due to the self-tightening and automatic wear compensation features of this coupler it is recommended that the locking

cylinder be disengaged at the end of each day.

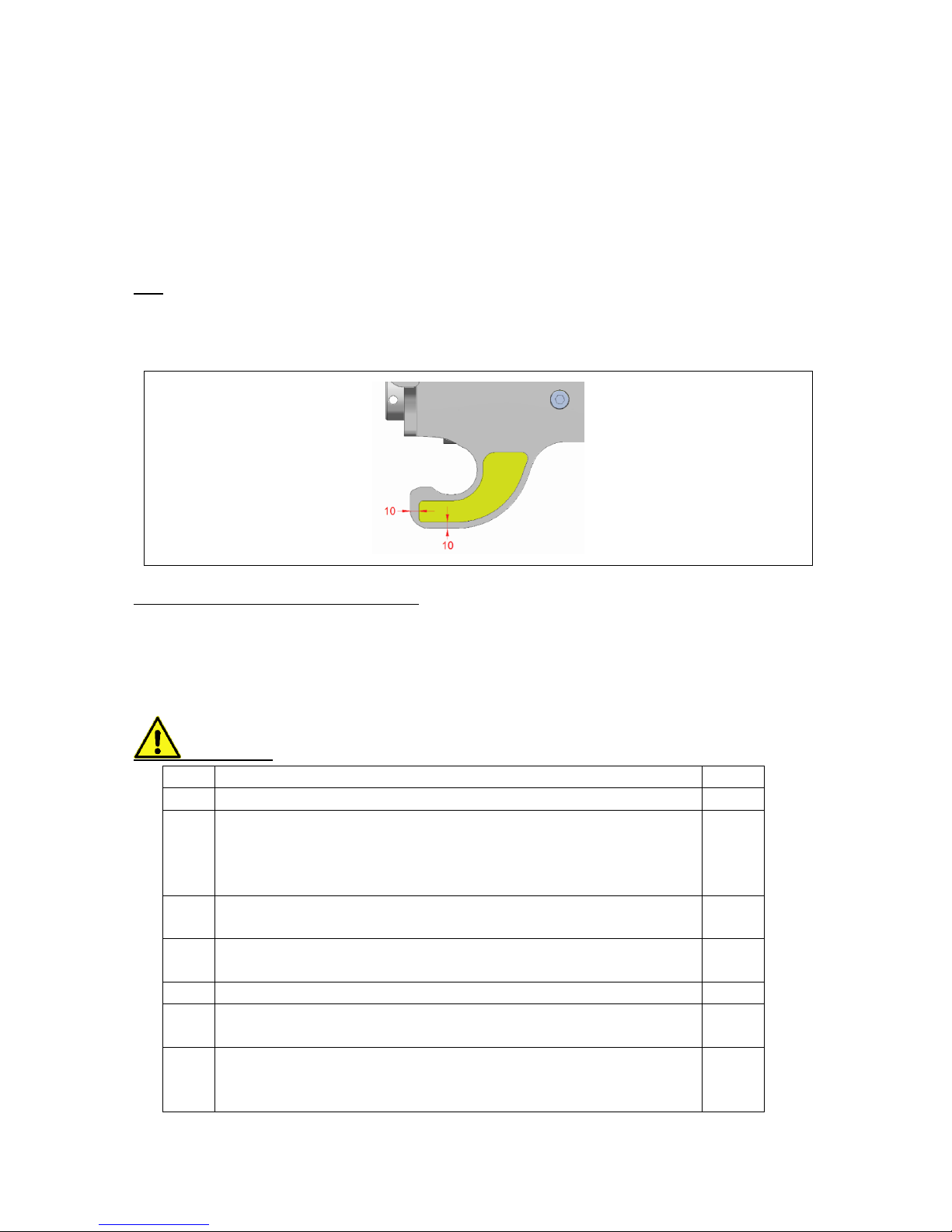

7. The D-Lock Quick Coupler is designed to take up wear, however if mounting pin wear exceeds 5% of the original

diameter, immediately replace implement pins.

8. All excavator operators should familiarise themselves with all coupler/attachment combinations before attempting to

operate the coupler. This should include, but be not limited to, practicing engaging and disengaging each attachment.

Furthermore when new attachments are added to the machine’s fleet, the operators should proceed with the same

“familiarisation” process before it is used on the job site.

9. Never use the Coupler as a prying tool.

10. Never use the Coupler as a clamping device.

11. In the event of a loss of engagement failure, the Jaw Locking Pawls and compression units MUST BE

REMOVED AND REPLACED