Publication: WBHLP08152022

Copyright 2022

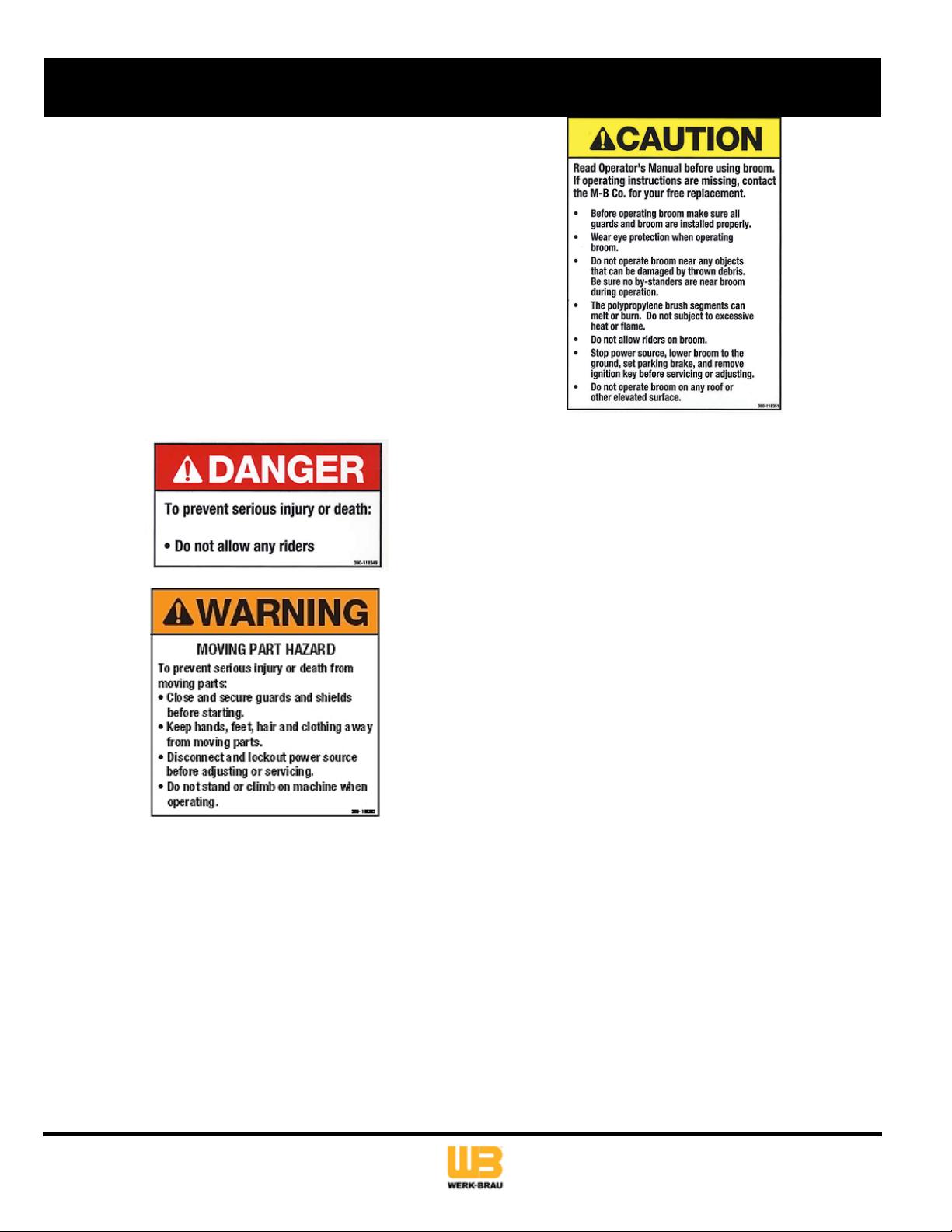

CAUTION! Indicates a hazardous situation or

unsafe practice which, if not avoided,

could result in minor or moderate

injury or property damage.

WARNING! Indicates a hazardous situation

which, if not avoided, could result in

serious injury or death.

DANGER! Indicates a hazardous situation

which, if not avoided, will result in

serious injury or death.

3

SAFETY

SAFETY ALERTS

Signal words and alert symbols notify of important safety precautions.

SAFETY DECALS

Although reading this manual and the safety instructions it contains

will provide you with the necessary basic knowledge to operate this

equipment safely and eectively, we have placed several safety

labels on the unit to remind you of this important information while

you are operating your unit.

All DANGER, WARNING, CAUTION, and instructional messages on

your unit should be carefully read and obeyed. Bodily injury can result

when these instructions are not followed. The information is for your

safety and it is important.

These labels will act as a constant visual reminder to you, and others

who may use the equipment, to follow the safety instructions

necessary for safe, eective operation.

If any of these labels are lost or damaged, replace them at once. See

your local dealer for replacements.

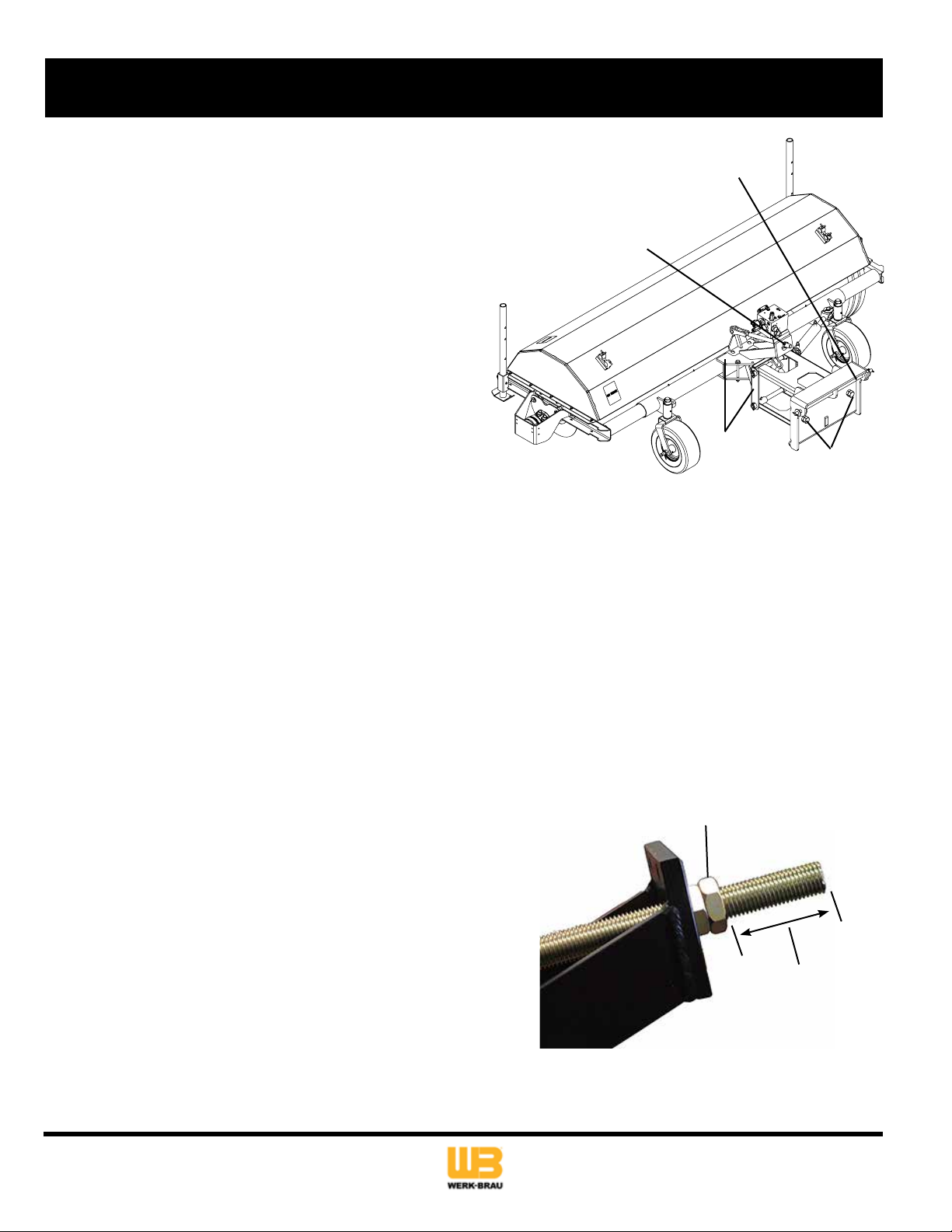

PRE-START GUIDELINES

• Install any covers or guards which may have been removed for

shipping purposes.

• Before starting equipment, walk around equipment, making a

visual inspection that all safety devices are properly installed and

secured.

• Check that all hardware, fasteners, hydraulic ttings, etc. are in

good condition and properly fastened. Replace any fatigued or

damaged items with proper replacements.

• Personnel who are not required to be in the work area should be

kept away. Never start the equipment unless you are absolutely

certain that everyone in the area is clear of the machine and

aware it is being started.

• Follow the manufacturer’s recommended start-up procedure.

OPERATION GUIDELINES

Read, understand and follow all instructions in the manual and on

the unit before starting.

NOTE: All reference to left, right, front or rear are given from the

operator position and facing forward.

• To avoid serious injury or death, do not modify equipment. Any

modications made to equipment can be dangerous and can void

equipment warranty.

• Never defeat a safety device to make a task easier.

• Always wear proper apparel when operating equipment; safety

glasses, face shield or goggles, ear protection, and dust mask. Tie

hair back. Never wear loose clothing or jewelry that could get

caught in moving parts.

• Never operate equipment with covers or guards removed. Rotating

parts can cause severe injury. Keep hands, feet, hair, jewelry and

clothing away from all moving parts.

• Only allow responsible adults who are familiar with the instructions,

to operate the unit (local regulations can restrict operator age).

• Clear the area of objects such as rocks, toys, wire, etc., which

could be picked up and thrown.

• Be aware of surroundings. Be sure the area is clear of other

people, bystanders or pets. Stop unit if anyone enters the area.

Indicates a hazardous situation

Indicates a hazardous situation

Indicates a hazardous situation

or unsafe practice which, if not