Pallet Leveler

Operating Instructions and Parts List

ATTENTION: To insure proper use of your WESCO Pallet Leveler, read these instructions thoroughly

before using. It is important that all personnel involved with the installation, maintenance

or operation of the Pallet Leveler read these instructions.

159228B

Specifications

Load Capacity: 400 to 4500 lbs., depending on springs

Load Size: 50" Wide x 50" Long x 72" High (max.)

WESCO Industrial Products, Inc.

1250 Welsh Road

North Wales, PA 19454

Tel: 215-699-7031 FAX: 215-699-3836

Contact the factory if you have start-up problems after

reading these instructions, or for parts information and

parts ordering. Unpacking

When unpacking your unit, check carefully for shipping

damage. If damage has occurred, file a claim with the

delivering carrier within 24 hours and notify the dealer

from whom the unit was purchased.

General Safety Information

WARNING: WESCO Pallet Leveler is designed to

automatically maintain a load at the ideal

height for loading or unloading. To insure

proper use, the following instructions must

be adhered to:

1. Wear safety glasses and gloves when setting up

and operating your Pallet Leveler.

2. Do not exceed the rated capacity. The rated

capacity is the total weight of both the pallet and

the load.

3. Do not use this unit with damaged or broken pallets.

4. Never operate the unit if the load is off center.

5. Never sit or ride on the turntable.

6. Keep a safe distance from the the turntable when it

is moving.

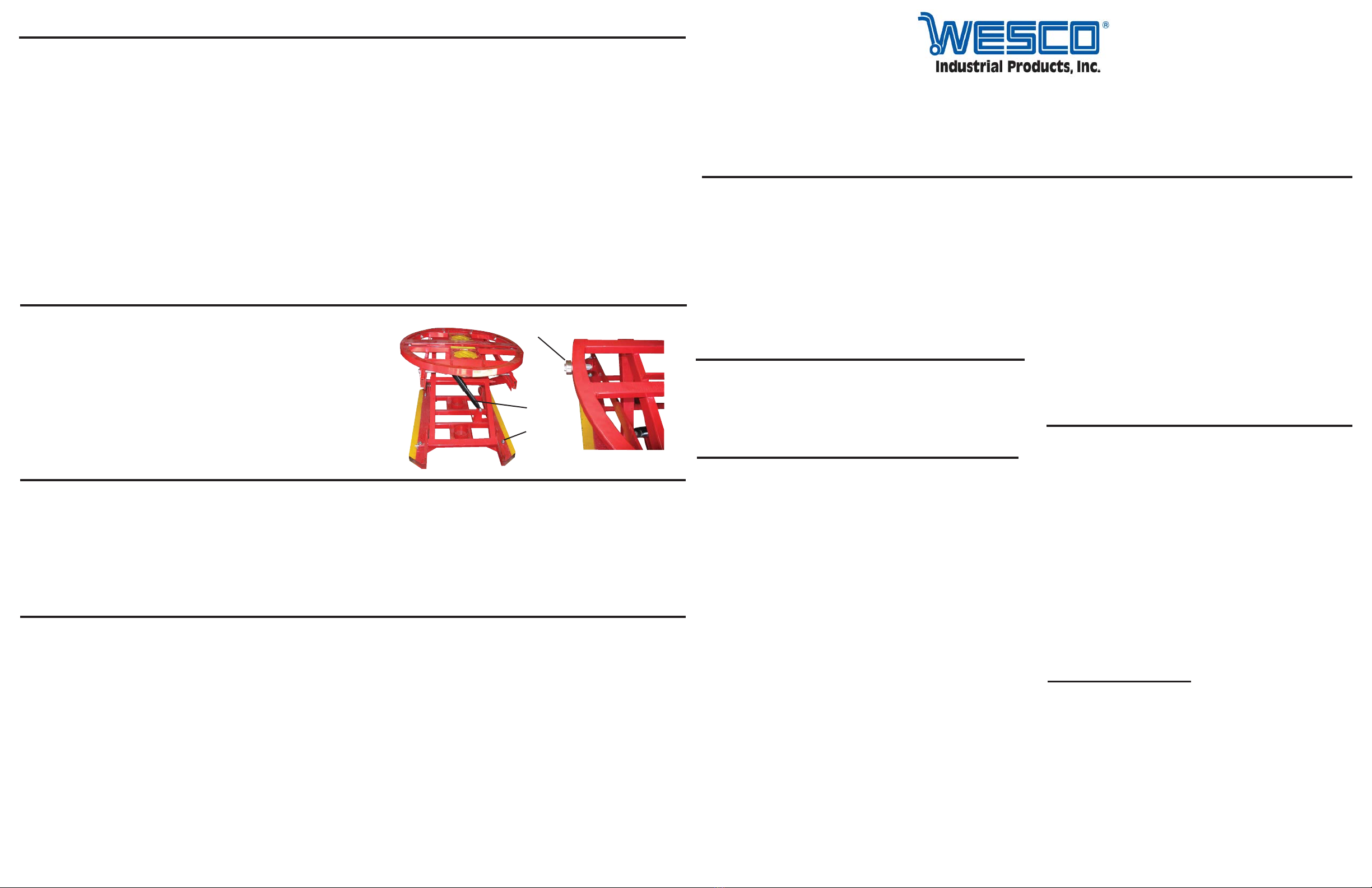

7. When installing the first (black) spring, have an

additional person to assist.

8. When installing the first (black) spring, use the

shock absorber pivot pin to support the frame

(Figure 1). This will prevent the frame from a

sudden drop.

9. Make sure after installing springs that they are

seated properly and that the spring locks are in

place.

10. When placing load on unit, make sure the

unit is supporting the weight, not the fork lift,

before removing the fork lift.

11. When removing a load with a fork lift, make

sure that the load is clear of the Pallet Lev

eler before moving the fork lift. If the load is

not clear of the Pallet Leveler, it may

suddenly release when the fork lift is

moved.

12. Never move the Pallet Leveler when it is

loaded. This would damage the base frame

since the fork pockets are designed to

support the weight of the unit, not the

extra load weight.

Start-up

1. Choose the place where you want to mount the

unit. The Pallet Leveler must be set up on a

clean andflat surface. Use optional leveling

pads

P/N 273000 to compensate for uneven floors.

2. Remove the plastic ties which secure the unit

to the base frame. Unpack three springs.

Remove all packing materials.

3. Check that frame of the unit is sitting firmly on

the floor. Pallet Leveler must be stable and

level. If unit is not level within 1/2" you must

use the optional leveling pads P/N 273000.

4. Remove the springs and place them on the

floor.

Installing the springs:

1. The Pallet Leveler can handle loads up to

4500 lbs. In order to adjust the Pallet Leveler

to adapt to different loads, the springs are

changed per the weight and height of the fully

loaded pallet. The Pallet Leveler may have

one to three springs, depending on the load.

Item Part No. Description Qty.

1 272988 Shock Absorber 1

2 272989 Bearing 16

3 272993 Spring: Black(not shown) 1

4 272994 Spring: *Ua\(not shown) 1

5 272995 Spring: 2raQJH (not shown) 1

6 272996 Kit: Hardware (not shown) 1

7 273000 Kit: Leveling Pad (optional) 1

Parts List

Warranty Repairs

If unit does not work properly, contact your dealer or the factory (215-699-7031), within one year of purchase date.

Non-Warranty Service

For units older than one year, repairs can be made easily on site with factory supplied parts, or repairs can be made at the

factory. NOTE: Do not send units to the factory for service without obtaining a “returned materials authorization" (RMA)

number from the service department. We will not be responsible for goods returned without proper authorization.

To Purchase Parts

A complete parts list with drawings appears in this manual. To order parts contact the factory at the phone or fax numbers

shown on page 1 of this manual. Ask for the Customer Service Department.l

LIMITED WARRANTY

Wesco Industrial Products, Inc. (WESCO) warrants to the purchaser of this product for a period of one year from the date of purchase

that this product shall be free of defects in material and/or workmanship, as follows:

1. WESCO will supply, at no charge, new or rebuilt replacements for any part that fails through a defect in material and/or workman-

ship during the warranty period.To obtain warranty service, you must deliver the product prepaid, to the WESCO factory.

2. This warranty does not cover any product or product part which has been subject to accident, misuse, abuse or negligence. WES-

CO shall only be liable under this warranty if the product is used in the manner intended by the manufacturer as specified in the written

instructions furnished with this product.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER.

ANY EXPRESS WARRANTY NOT PROVIDED IN THIS WARRANTY DOCUMENT, AND ANY REMEDY FOR BREACH OF CON-

TRACT THAT, BUT FOR THIS PROVISION, MIGHTARISE BY IMPLICATION OR OPERATION OF LAW, IS HEREBY EXCLUDED

AND DISCLAIMED. UNDER NO CIRCUMSTANCES SHALL WESCO BE LIABLE TO PURCHASER ORANY OTHER PERSON FOR

ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER ARISING OUT OF BREACH OF WARRANTY, EXPRESS OR

IMPLIED, A BREACH OF CONTRACT OR OTHERWISE. EXCEPT TO THE EXTENT PROHIBITED BYAPPLICABLE LAW, ANY

IMPLIED WARRANTY OF MERCHANTABILITYAND FITNESS FOR ANY PARTICULAR PURPOSEARE EXPRESSLY LIMITED IN

DURATION TO THE DURATION OF THIS LIMITED WARRANTY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on how long any

implied warranty lasts, so the above limitations may not apply to you. This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state. © Copyright 2008 Wesco Industrial Products, Inc.

1

7

2

Troubleshooting

PROBLEM CAUSE CHECK

Unit lowers too easily. Wrong spring configuation, Check spring ratings,

springs too weak for load. Refer to table 1A and 1B.

Unit lowers too hard. Wrong spring configuation, Check spring ratings,

springs too strong for load. Refer to table 1A and 1B.

Top of unit rotates away Unit may not be level. Move to level surface or install

from operator. operational leveling pads, P/N 273000.

Top of unit bounces. Shock absorber damaged. Replace shock absorber.

Excessive "Rumble" when Damaged bearings under Replace bearings.

in operation. turntable.