6 Technical specifications.......................................................................................18

6.1 General technical data CM2 XL.................................................................................18

6.2 Variant CM2 XL .............................................................................................................19

7 Assembly, first start-up........................................................................................21

7.1 Safety...............................................................................................................................21

7.2 Assembly.........................................................................................................................21

7.3 First start-up....................................................................................................................21

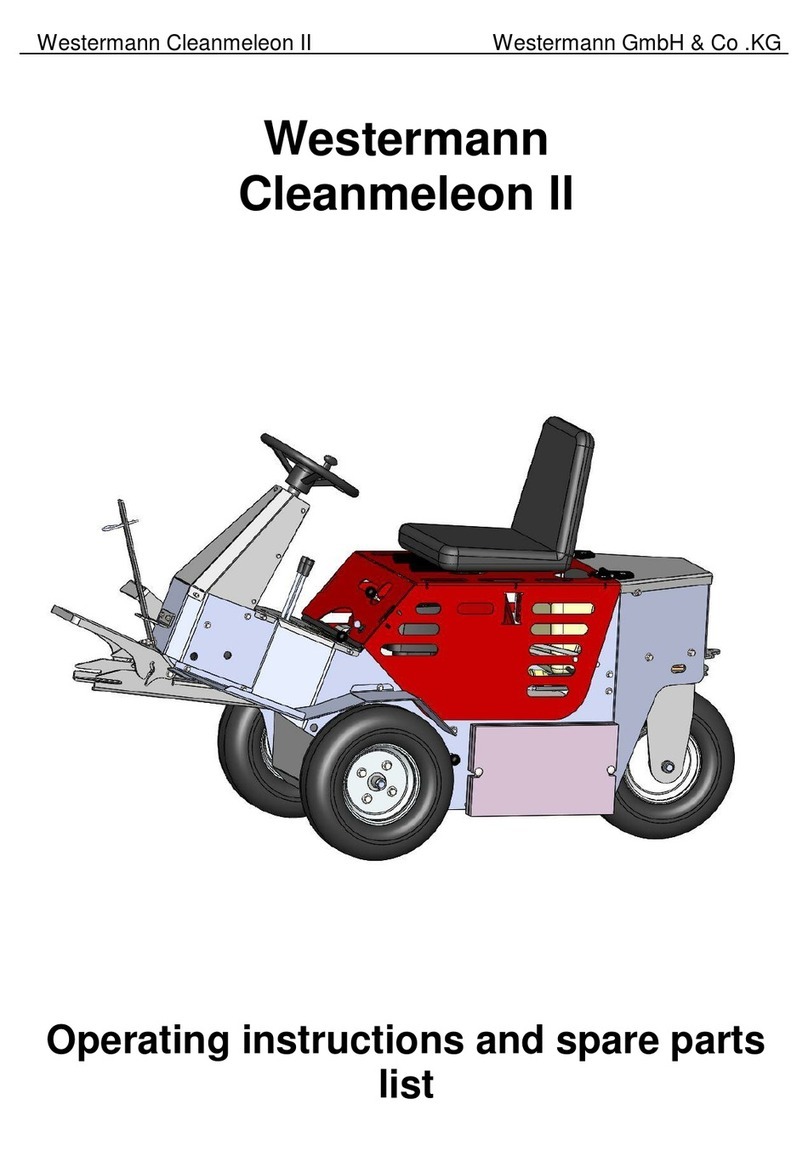

8 Product description..............................................................................................22

9 Control.................................................................................................................23

9.1 Controls............................................................................................................................23

10 Start-up.........................................................................................................24

10.1 Checking the engine before start-up.........................................................................24

11 Operation......................................................................................................25

11.1 Starting | Stopping the CM2 XL ...............................................................................25

11.2 Running-in period..........................................................................................................26

11.3 Short engine running time............................................................................................27

11.4 Functional overview ......................................................................................................27

12 Attachments..................................................................................................29

12.1 Attachment of the equipment......................................................................................30

13 Maintenance and servicing............................................................................31

13.1 General ............................................................................................................................31

13.2 Table of regular inspections........................................................................................33

13.3 Screw connections........................................................................................................34

13.4 Tensioning the V-belt....................................................................................................34

13.5 Replacing the V-belt......................................................................................................35

13.6 Tensioning the lock chain............................................................................................35

13.7 Cleaning/replacing the air filter...................................................................................35

13.8 Procedures after maintenance ...................................................................................36

13.9 Notes regarding maintenance work...........................................................................36

13.10 Documentary list............................................................................................................36

14 Residual risks................................................................................................37

15 Storage conditions ........................................................................................39

16 Troubleshooting............................................................................................40