9

Filling should only be performed by a suitably trained person and only following a full risk

assessment.

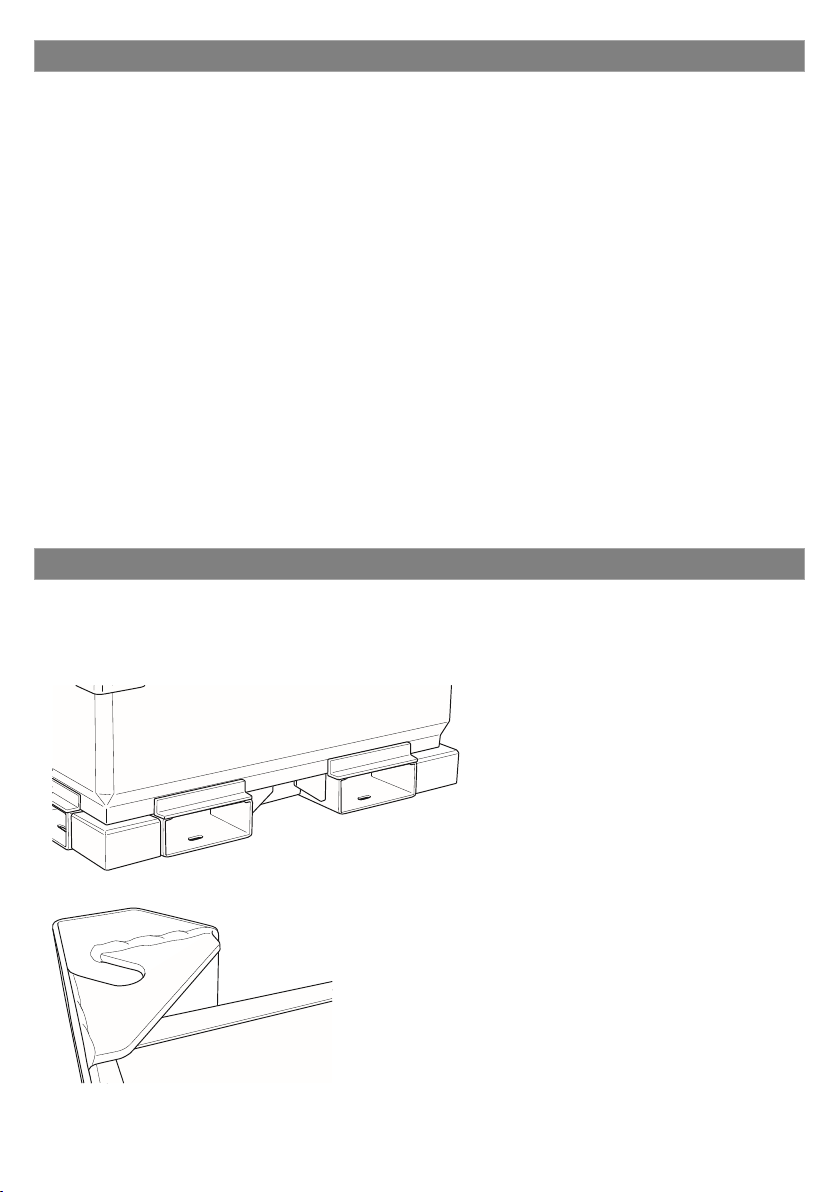

The IBC must be positioned on a firm level surface, whether static, truck or trailer mounted.

Where truck or trailer mounted, ensure that the parking brake

is set to ON and the wheels are chocked.

Before filling, ensure that you have a suitable spillage kit and

that you are wearing all required PPE.

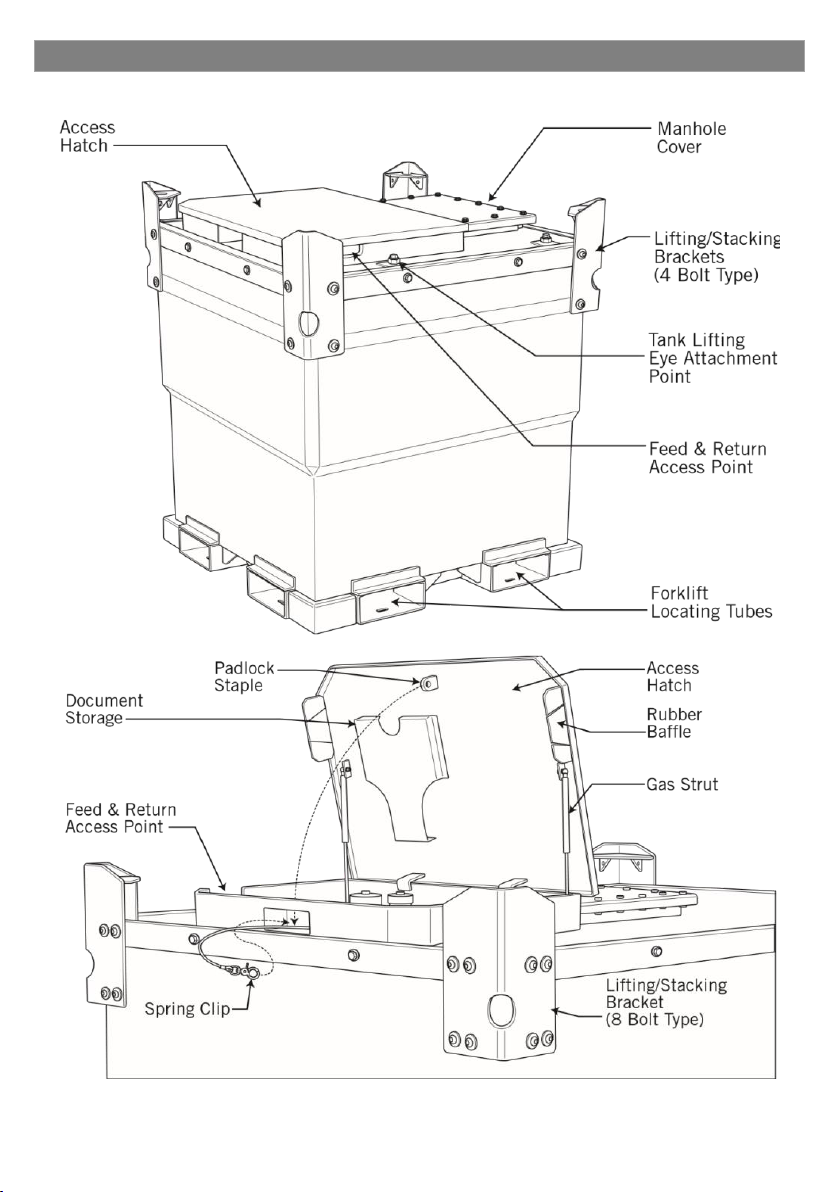

Unlock or unclip the access hatch, then open fully until it is held

open by the gas struts. Unscrew and remove the 3in male

nipple open filler cap and if not retained by a security chain,

place somewhere safe and clean.

Fill the IBC manually do not hard couple to the supply tank.

NOTE; The maximum quantity of fuel the IBC may be filled with is 95% of the IBC’s capacity.

Refer to the specification section for exact quantity for the model IBC you have.

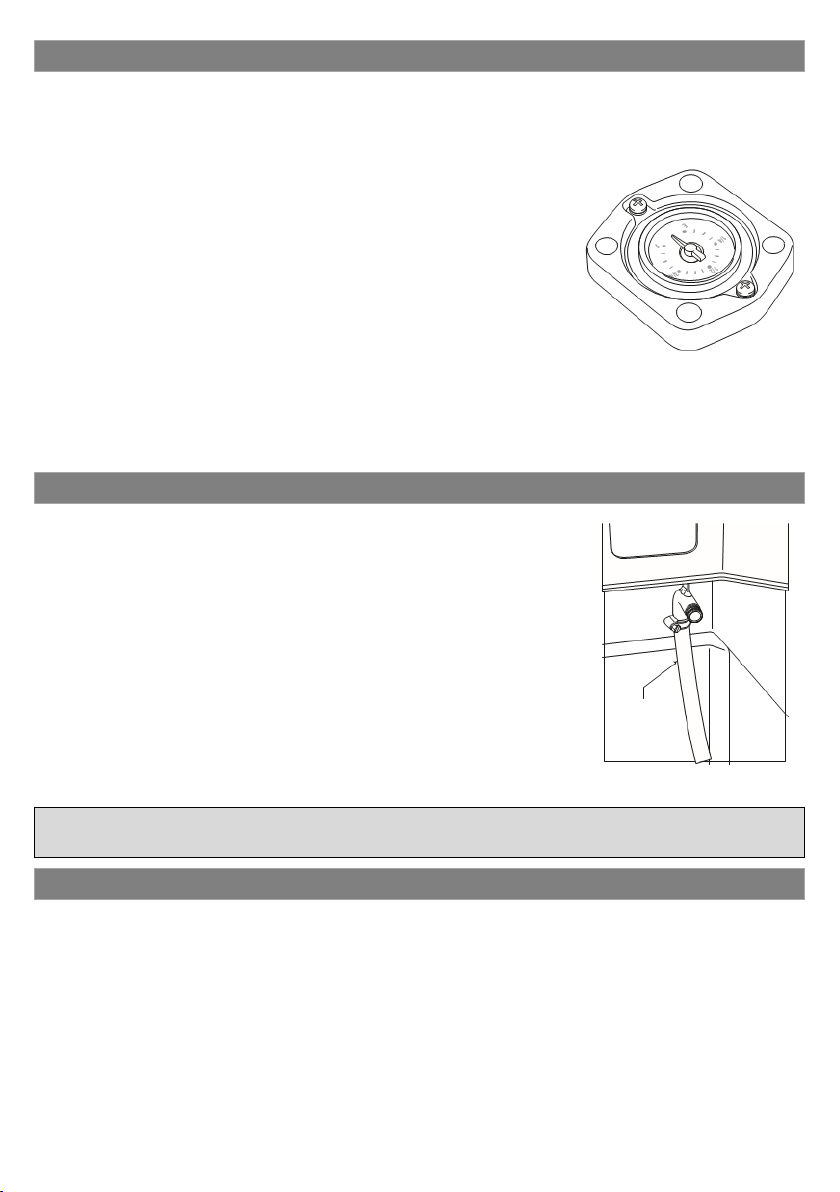

Observe the fuel level gauge for an indication of tank capacity then once filled, replace the

filler cap and clean up any fuel spillages.

The IBC bund area safeguards against any spillage exiting the

unit and polluting the immediate area. The bund is designed to

retain up to 110% of the unit’s maximum storage capability.

Though it is of a high capacity, any fuel entering the bund area

should be attended to as soon as possible without allowing the

quantity to simply increase.

The bund should be kept empty as much as possible and should

the need arise to empty it, there is a bund emptying pipe fitted

within the bund area.

Fitted to the front right hand side of the unit, under the access

hatch, simply connect a suitable pump to the captive fitting and

empty into a waste container.

WARNING

Waste may only be collected by a registered carrier.

Should a spillage occur when emptying the bund, or when filling or transferring fuel, clear

the spillage as quickly as possible using absorbent material. Ideally, you should use a

dedicated spillage kit which will contain all the necessary items to retain and remove such a

spillage.

DO NOT hose the area down or use any detergents. DO NOT allow the fuel to enter drains

or water courses.

Spillages must be reported to the environment Agency Hot Line (0800 807 060).

All material used to retain and remove a spillage should be bagged and collected by a

registered carrier.