TABLE OF CONTENTS PAGE

Introduction

...................................................................................................

1

Serial Plate Locations ........................................................................................

..

1

Safety

...

............................................................................................

.

.........

3

Safety Decals

...............................................................................................

4,5

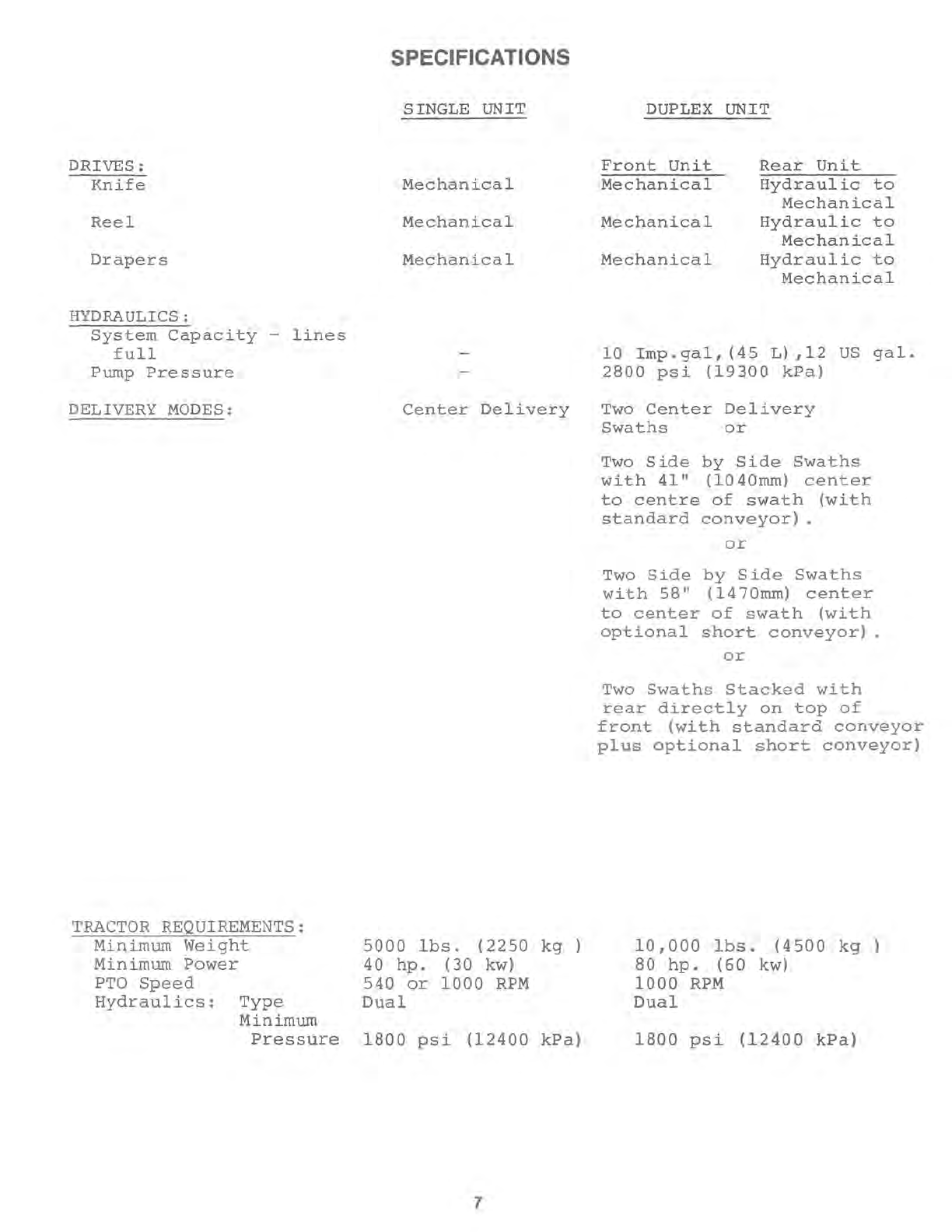

Specifications

...............................................................................................

6,7

Operation

At

First

Use-

Electrical Hook-Up

.............................................................................

8,9

-

PTO

Adjustment

.............................................

....

...............................

10

-Optional Hitch Plate

.........................

.......

............................................

11

-Duplex Initial Field Adjustments

..............................................................

11,12

-Hydraulic Oil Filter

..............................................................................

12

-

Wheel

Bolts

...........................................

............

...................

..........

12

Switch

Box

...................................................................................................

13

Pre-Season Check

............................................................................................

14

End of Season Check

..........................................................................................

14

Transporting-General

........................................................................................

15

-Single Unit -Field to Transport

.................................

..........

........................

16

-Single Unit -Transport to Field

................................................................

17,18

-Duplex Unit -Field to Transport

...........................

...

.................................

19-22

-Duplex Unit -Transport to Field

............

..

.................................................

23-26

Changing Modes of Delivery -Description of Modes

..............................................................

26

-Center to

End

...•................................................................

27

-Conveyor Extension Package (Option)

..............................................

28

To

Separate and Re-Connect Duplex Units

........................................................................

29

Duplex Operating Tips

.............................................

........

.................

............

.....

30,31

Trouble Shooting

Swath Formation: Center Delivery

..............................................................................

32

Crop Loss at Cutter Bar

.......................................................................................

33

Crop Loss at Drapers

..........................................................................................

33

Transport

.....................................................................................................

34

Drives

..............................................

. . .

.....................

...

............................

35,36

Duplex Tracking

..............................................................................................

37

Duplex Cornering

..........................................................................................

38,39

Duplex Swath Formation: End Delivery

.........................................................................

40

Duplex Hydraulic System

......................................................................................

41

Duplex Electrical System

......................................................................................

42

Duplex Transport & Conversion

................................................................................

43

Duplex Center Deck

...........................................................................................

43

Adjustment & Maintenance

Main

Drives -Idler

Alignment

...............................................................................

44

-Belt Tension

.........

...............

..........

.................................

...............

44

-Rear Unit

Main

Drive Belt Tension

..............................................................

45

-Rear Unit Clutch Drive Belt Tension

............................................................

45

Knife -Drive Belt Tension

........................................

..............

...............

.

.............

46

-Maintenance

...........................................................

......

.....

...

...............

47

Reel -Horizontal Position

...................................................................................

48

-Safety Props

.........................................................................................

48

-Clearance From Cutterbar

................................................

.........

...............

...

.

49

-Centering

...........................................................................................

49

-Drive Idler Position

...................................................................................

50

-Primary Drive Belt Tension

...........................................................................

50

-Final Drive Belt Tension

......................................................

.

...............

........

51

-Speed

................................................................

........

.......................

52

Drapers -Tracking

.......................................................................................

53,54

-Tension

.............................................

..

........

...........

........................

54

-Speed

............................................................................................

55

-Drive Belt Travel

..................................................................................

55

-Delivery Opening

..................................................................................

56

Head Lift Cylinder Stop

........................................................................................

57

Header Float

..................................................................................................

57

Wheel

Alignment

..............................................................

......

.........................

58

Trail

Width

....................................................................

...........................

....

59

Telescoping Hitch Shear Bolt

..................................................................................

59

Duplex Hitch -Rear Machine Overlap

......................................................................

60,61

-Hitch Spring

..................................................................................

62

Front Wheel Steering Spring

...................................................................................

62

Front Wheel Support Dis-assembly

.............................................................................

63

Hydraulic System-Maintenance

..............................................................................

64

-Single

Unit

Schematic

.....................................................................

64

-Duplex Unit Schematic

....................................................................

65

Electrical System -Schematic

................................................................................

66

Lubrication & Periodic Maintenance-

10

Hour

.................................................................

67

-

50

Hour

.................................................................

68

-

End

of Season

........................................................

69-71

A~~~~~I~harts

.............................................................................................

72-75

Single Unit or Front Duplex Unit

............................................................................

76-95

Rear Duplex

Unit

........................................................................................

96-117