5

Westward Operating Instructions and Parts Manual 22XP38, 22XP39

Drain Cleaning Machine

3.Groundedtoolsmustbepluggedintoaproperlyinstalledandgroundedoutlet,whichisin

accordancewithallsafetycodesandordinances.Nevermodifythepluginanymanner.Do

notremovethegroundingpin.Neveruseanyadapterplugs.ChecktheplugswithUL

approvedtestersorconsultwithacertifiedelectricianifyouarenotsurewhetherthe

powersourceisproperlygrounded.Shouldtheelectricaltoolmalfunctionorstopworking,

groundinggivesasafewaytokeeptheoperatorfromelectricalshock.

4.Useastraightelectricplug,sothattheoperatorcancutthepoweroffimmediatelyby

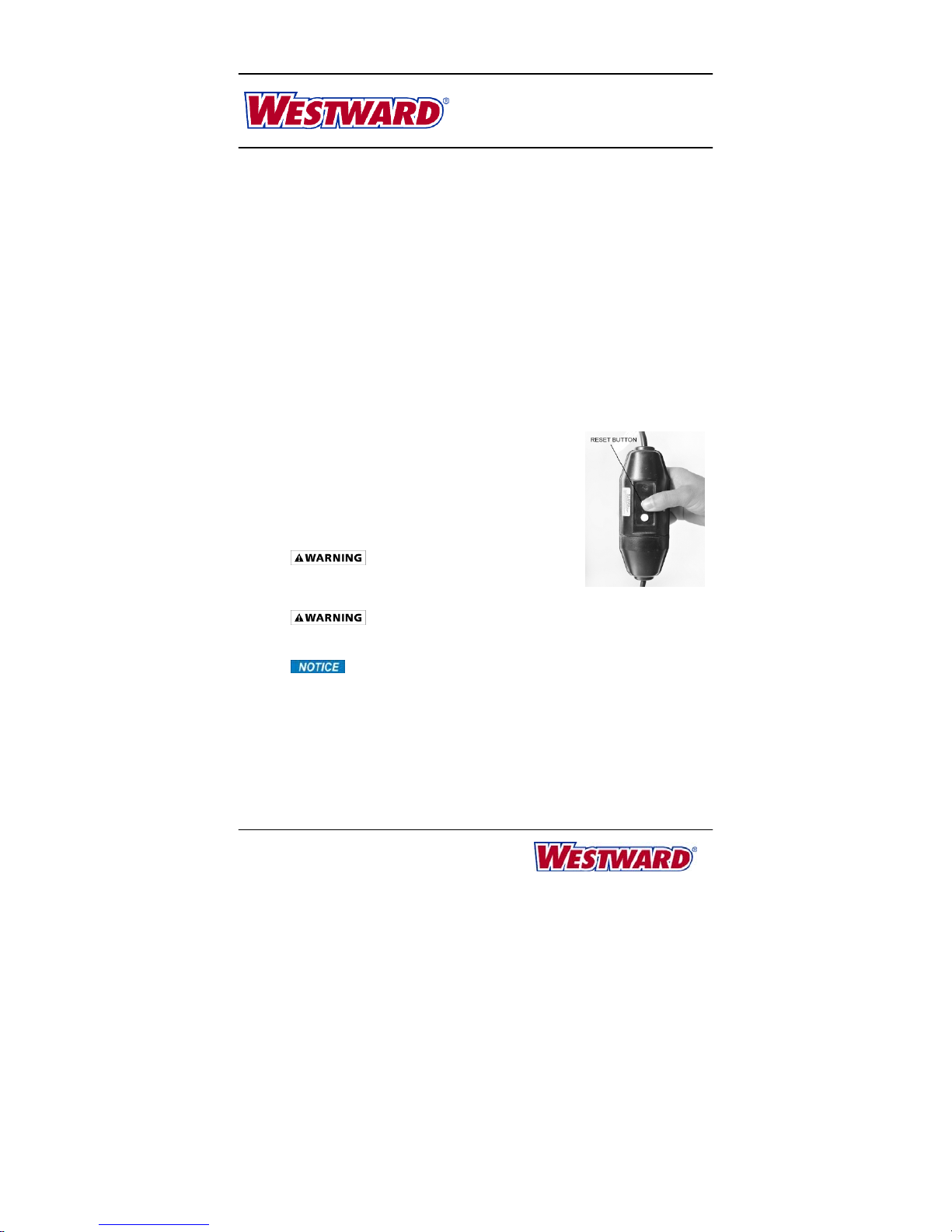

pullingtheplugofftheseatonthewall.Inaddition,checktheshockprotectortomake

sureitworksproperly.Failuretofollowinstructionsmayresultinseriousinjuryordeath.

5.Neverleavethepowermachineinrainorinwetconditions.Wetmachinesoftencause

electricshock.

6.Donotallowyourbodytocontactanygroundedsurfacessuchasradiators,rangespipes,

andrefrigerators.Itisverydangeroustobeelectricallyshockedwhenyourbodyis

grounded.

7.Neverabusetheelectricalcord.Donotusethecordtopulltheplugfromanoutletanddo

notusethecordtocarrythemachine.Keepthecordawayfromheat,oil,sharpedges

and/ormovingparts.Replacedamagedcordsimmediately.Damagedcordsincreasetherisk

ofelectricshock.

8.Nevertouchplugsortoolswithwethands.Keepallelectricalconnectorsdryandoffthe

groundtoreducetheriskofelectricshock.

9.Usemachine’sratepowertospecifyfusesonyourpowersupply.Neveruseothermetal

wirestoreplacethespecifiedfuses.Failuretofollowthisrulemaycauseseriousinjuryor

evendeath.

PersonalSafety

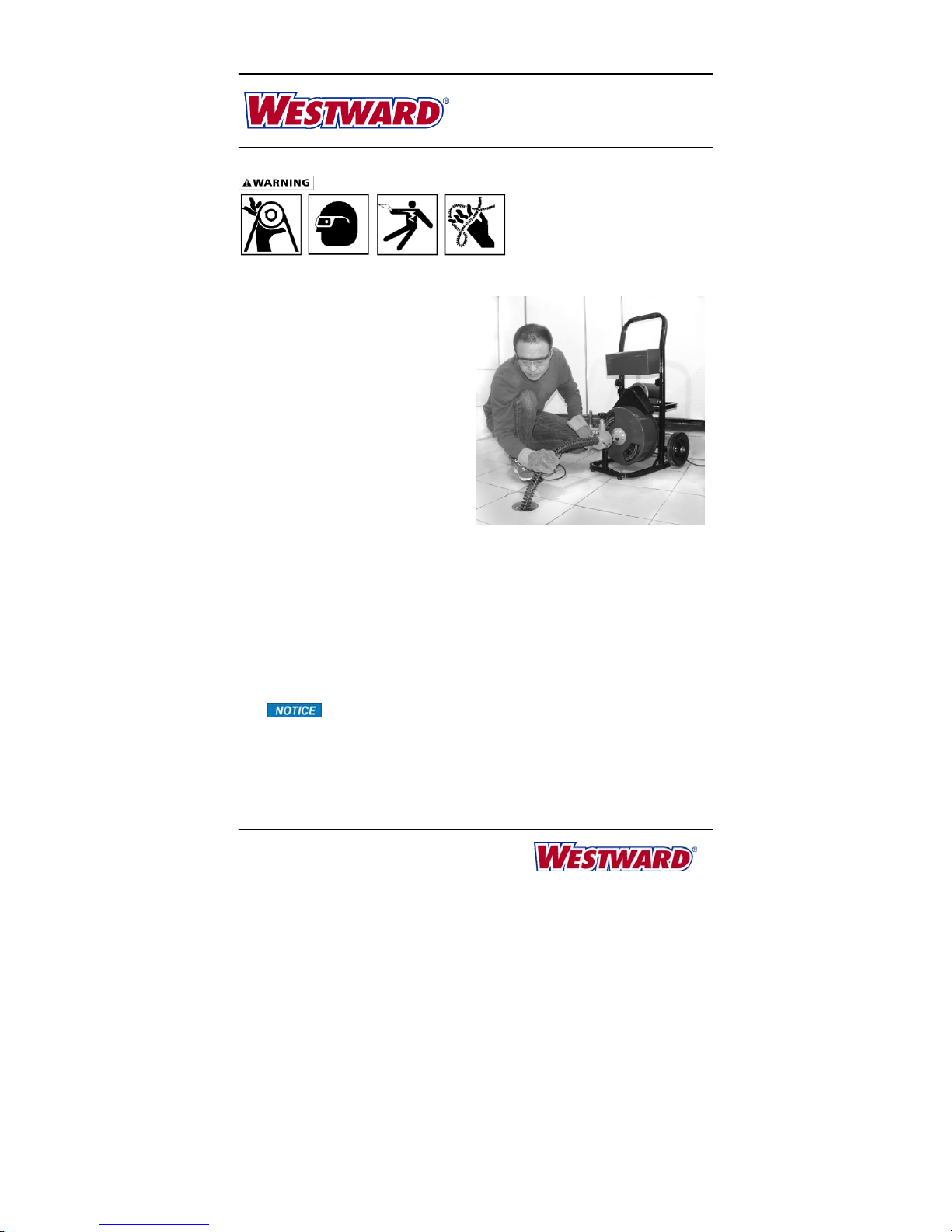

1. Wearproperworkingattire,rubber‐solednon‐slipshoes,safetyglasses,dustmask,hard

hat,hearingprotectionandleathergloveswhenoperatingthemachine.Failuretofollow

thisrulemaycauseseriousinjuryorevendeath.

Nevergrasparotatingcablewitharagorclothglove.Graspingthe

rotationalcablemaycausehandorfingerstobecaughtonthecableandleadtopersonal

injury.

2. Neveroperatemachinewithbeltguardremoved.Keephandsawayfrompulleyandbelts.

Fingerscangetcaughtbetweenbeltandpulley.

3. Keephandsawayfromtherotatingdrumanddistributingcone.Donotreachintothedrum

unlessthemachineisunplugged.Handmaybecaughtinthemovingpartsresultingin

seriousinjury.

4. Bealertatalltimes.Keepgoodjudgmentwhenoperatingamachine.Neveroperate

machineunderinfluenceoffatigue,drugs,alcoholormedications.Asinglesecondof

inattentioncanleadtoalifetimeofregret.

5. Dressneatly.Donotwearlooseclothingorjewelry.Keephairtiedand/ortuckedaway.

Keeplonghair,clothes,andglovesawayfrommovingparts.Sucharticlesmayresultin

seriousinjuryordeathwhencaughtinthemachine.

6. Avoidaccidentalstartingofthemachine.MakesuretheRotationSwitchissetatOFF

positionbeforepluggingin.Pluggingintoolsthathavetheswitchon

invitesaccidents.

Note:ThismachinehasaRotationSwitchandanAir‐ActivatedFoot

Switch.TheRotationSwitchisusedtosetthemotoranddrum

rotatingdirection.Ithasthreepositions,representingForward

rotation(FOR),OFF,andReverserotation(REV),respectively.When

readytowork,settheRotationSwitchtoFORandthenpressthe

FootSwitchtoletthemachinerunintheforwarddirection.Stop

machinefirstandwaitforfewsecondstoallowthemachinetostop

beforechangingtherotationdirection.

7. Makesureadjustingkeysareremovedbeforeturningthetoolon.Awrenchorkeythatis

thrownfromarotatingpartofthemachinecanresultinseriouspersonalinjuryordeath.

8. Donotoverreach.Keepproperfootingandbalanceatalltimes.Properfootingandbalance