CONTENT

1Safety...................................................................................................................................................... 5

2Summary................................................................................................................................................. 1

2.1 Model instruction.............................................................................................................................1

2.2 Main features ...................................................................................................................................1

2.3 Usage ...............................................................................................................................................1

2.4 Working condition and environment................................................................................................1

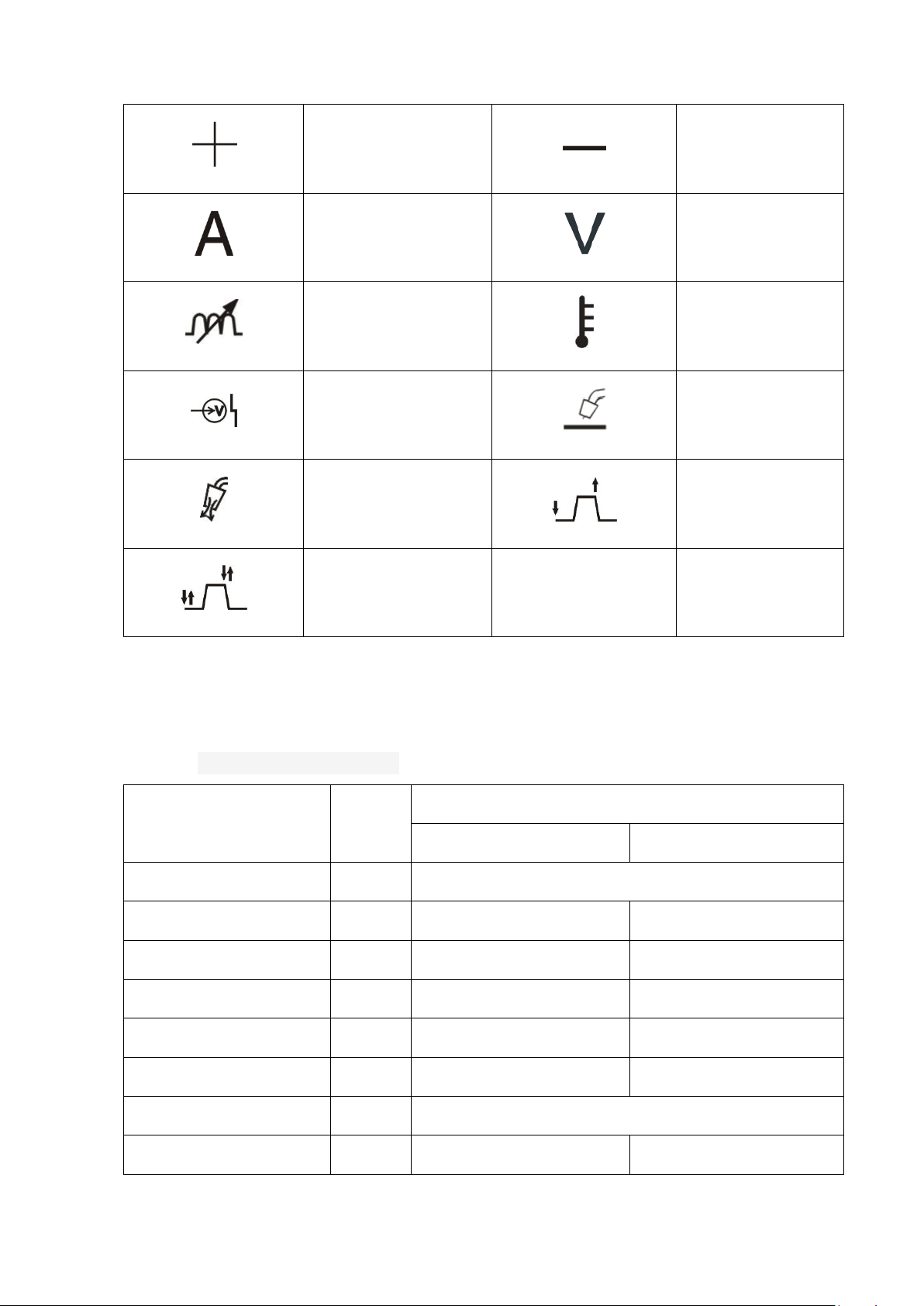

2.5 Symbol instruction...........................................................................................................................1

3Specifications.......................................................................................................................................... 2

3.1 Main technical parameters...............................................................................................................2

4Panel and function................................................................................................................................... 3

4.1 Front panel function.........................................................................................................................3

4.2 Down front panel .............................................................................................................................4

4.3 Rear panel instruction ......................................................................................................................5

5Installation .............................................................................................................................................. 5

5.1 Power supply requirement ...............................................................................................................5

5.2 Power cable connection ...................................................................................................................6

5.3 Welder and wire feeder connection..................................................................................................8

5.4 Gas cylinder and gas regulator connection .....................................................................................8

6Operation ................................................................................................................................................ 8

6.1 Pre-operation preparation and inspection confirmed items and methods and requirements............8

(1)Preparation of safety equipment...............................................................................................8

(2)Checking after connection .......................................................................................................9

(3)Wire installation.......................................................................................................................9

6.2 Weld operation...............................................................................................................................10

(1)4-Step weld operation(Non initial).........................................................................................10

(2)2-Step weld operation(Non initial and crater)........................................................................11

7Weld condition example........................................................................................................................ 12

8Working principle ................................................................................................................................. 15

8.1 Working principle ..........................................................................................................................15

8.2 Drawing .........................................................................................................................................15

8.3 Component list...............................................................................................................................16

9Maintenance and repairing.................................................................................................................... 16

9.1 Maintenance...................................................................................................................................16