Wexxar BEL 180 User manual

Operator Manual 65-34-5 Effective APRIL 21, 2010

BEL 180

SEMI-AUTOMATICRANDOM/SELF-ADJUSTING

UNIFORMTOPANDBOTTOMCASETAPESEALER

©Belcor Division of Wexxar Industries Inc.

Phone (604) 270-0811 • Fax (604) 270-7897

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 2

Introduction

The BEL 180 is capable of applying pressure-sensitive tape to both the top and bottom of various

size cases presented to the machine at random or without manual adjustment between sizes. In

addition, the machine features the ability to use the random function to automatically adjust to a

uniform case size and lock itself in position for longer runs of a single case size.

The features of the BEL 180 are:

DEKKA CADET - 2” high performance tape heads

A special sensor system that activates the dynamic case height adjustment while eliminating a

potential pinch point. Moving parts are concealed by design and by guarding to a high

standard of safety

A stainless steel controls enclosure with logic controller and a second conveniently placed

start/stop switch at the front of the top tapehead holder. There is a solenoid valve as well as a

manual valve for compressed air supply.

Roller infeed section for easier case entry

A robust vertical actuator system for moving the top drive and tape head. It uses air cylinders

with pneumatic rod locks to secure the random case size adjustments, lock the machine in

position for uniform case sizes in ‘Lock’ mode and for safety to prevent unexpected

movement in the case of a sudden electrical or pneumatic power failure.

A tilt-up bottom tapehead holder for easier access to replace the tape roll or remove the

bottom tapehead from the machine.

Heavy duty stainless steel frame.

Interlocked enclosure guard doors.

Standard Specifications:

Length Width Height

Case Size Range Minimum 6” / 152mm 6” / 152mm 6” / 152mm

Maximum 72” / 1829mm* 17” / 432mm 19” / 483mm

*can be made longer

Machine Dimensions 46” / 1175mm 36” / 889mm 54” / 1372mm

In/Outfeed Height Frame 23.5” / 597mm

With adjustable leg extensions

[foot pad] Minimum

Maximum

23.5" / 597mm

30” / 762mm

Speed Up to 10 cases / min.

Shipping Weight Approx. 500 lbs. / 227 kg.

For further detail, see Layout Drawing 75-678

65-34-5 4/21/10

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 3

Table of Contents

BEL 180 Main Controls & Function Reference................................................................. 4

Connecting Power............................................................................................................... 5

Electric........................................................................................................................ 5

Compressed Air .......................................................................................................... 5

Installing & Removing the Tape Heads.............................................................................. 6

Bottom Tape Head.......................................................................................................... 6

Top Tape Head................................................................................................................ 8

Top Tapehead Downward Force [Pressure Regulator] Adjustment................................... 9

Conveyor Side Force [Pressure Regulator] Adjustment................................................... 10

Feeding Cases to the Machine .......................................................................................... 11

Automatic Random Case Size Operation ..................................................................... 11

Self-Adjusting Uniform Case Size Operation – ‘Lock’ Mode ..................................... 12

Troubleshooting Guide ..................................................................................................... 14

Section 1 - Corrugated Case Quality and Specifications.............................................. 14

General Taping Conditions........................................................................................... 15

65-34-5 4/21/10

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 4

BEL 180 Main Controls & Function Reference

Machine Status Light

• Steady Green – Ready

• Flashing Green – Bottom tape

head raised and ready to access

• Quick-Flashing Green – Machine

or cycle fault

Control Station

• E-stop

• Reset

• Self-Adjustment

lock function

Front Guard doors

with key interlock

switch

Bottom tape head tilt-up lever

Main Air Supply

• Manual and solenoid air

shut-off valves

• Air filters

Main Controls Enclosure

• Main Electrical Power

Shut-off

• Top tape head lift

switch

• Conveyor drive test

Side belt conveyor

and top tapehead

pressure (force)

adjustment

Bottom tape head

Top tape head

65-34-5 4/21/10

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 5

Connecting Power

Electric

The BEL 180 is single-phase 110-120 VAC. The conveyor drive system is powered by

dual gear-motors that together draw 5.5 amps.If required, a minimum 14 gauge (AWG)

power extension cord with standard three pin connection must be used to connect the

machine to the power source.

Compressed Air

The BEL 180 requires an air supply that must be clean and dry and at an optimal pressure

of 80 PSI. The volume of air required is 0.02 CF/cycle at 80 PSI (6 Bar). The air supply

line must be of sufficient diameter to provide an adequate amount of air without pressure

drops when the machine is cycling. A ½” air line size is recommended.

One of the most common causes of inconsistent machine performance is inadequate air

supply. Therefore, meeting machine air requirements is important to assure satisfactory

operation.

The BEL 180 is equipped with both solenoid and manual compressed air shut-off / dump

valves and a filter/regulator which should be checked daily to ensure that the air pressure

is adjusted to the proper setting, and any water drained from the filters. The BEL 180

does not use lubrication in the compressed air supply.

Pneumatic Controls

Compressed air

connection

Filter Water Drains

Solenoid Control

Valves

Manual Shut-off

/ Lockout Valve

Main Machine

Pressure

Regulator

Main Air Supply

Solenoid Valve

Pressure Regulators for

Side Belt Conveyor

Gripping Force and Top

Tapehead Downward

Force [see pages 9 & 10]

65-34-5 4/21/10

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 6

Installing & Removing the Tape Heads

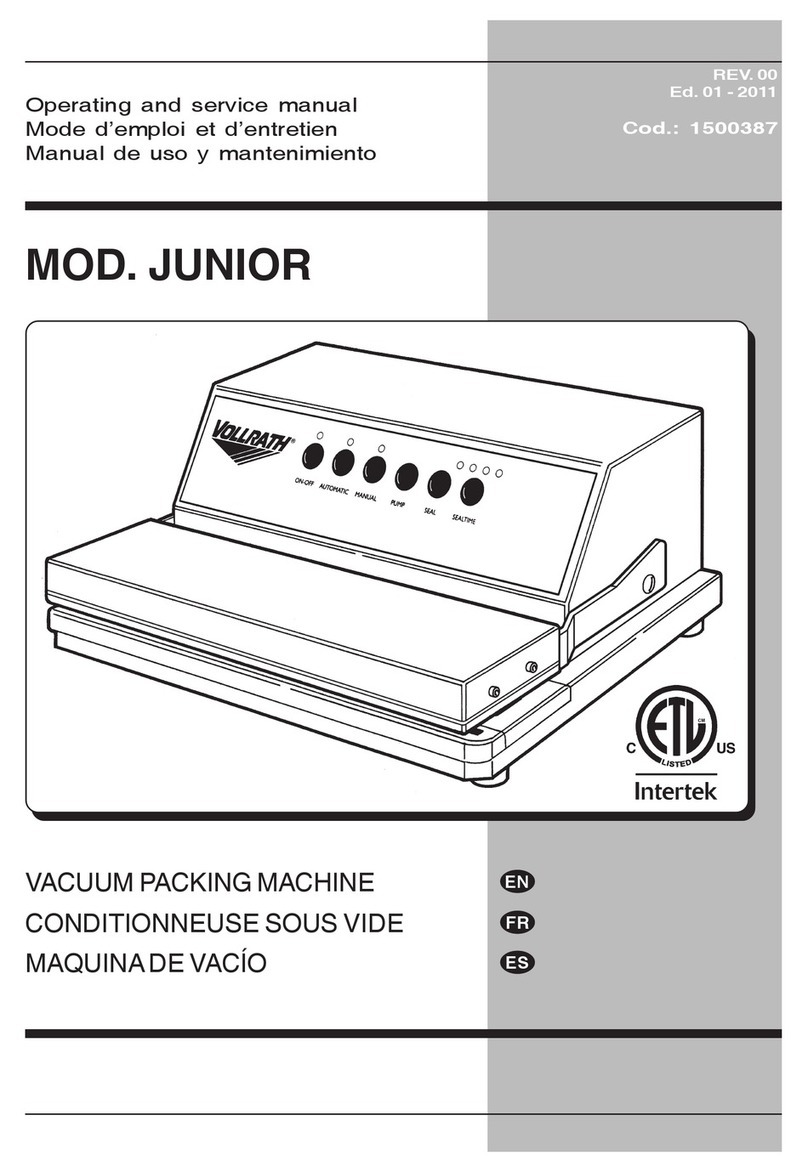

Tape dispensing heads are mounted with pins on their sides that fit into corresponding slots in the

upper and lower tape head mounting positions.

Bottom Tape Head

The bottom tapehead is installed and removed by using the manual lever to rotate it up and out of

the bottom conveyor rollers. It is first necessary to raise the top tapehead holder to be out of the

way using a switch on the main controls enclosure.

1. With the machine power turned on and all the guard doors closed, turn the TAPE

HOLDER selector switch on the main control panel to ‘UP’. The top tape head holder

will raise it to its maximum height and lock in position, making the bottom tape head

accessible. The green light on top of the machine will flash quickly indicating that the

machine guard door can be opened to reach the bottom tape head.

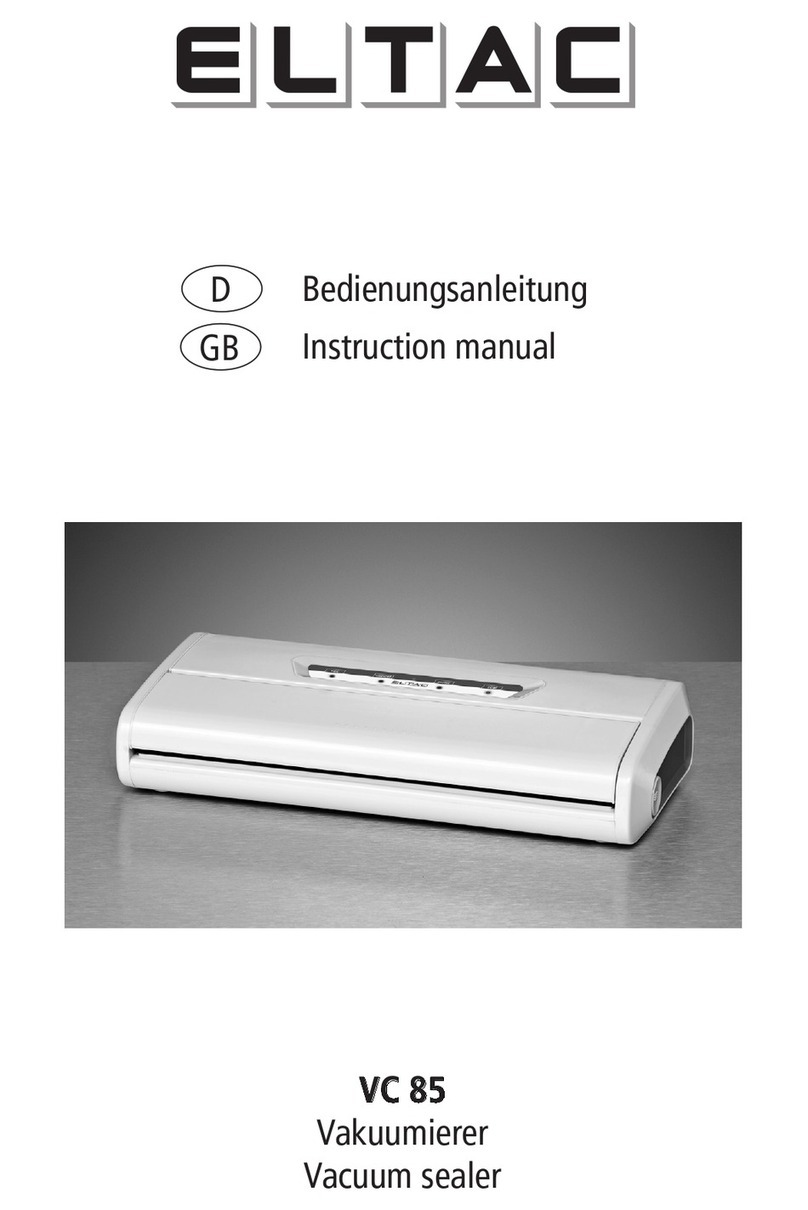

2. Pull the bottom tapehead holder lever towards you to rotate the bottom head up and out of

the bottom machine frame. The lever has a latching pin to secure it in the up position.

65-34-5 4/21/10

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 7

3. On the right side of the holder at the top in the raised position, there is a latch that locks

the tape head into the holder. It must be released to remove the head from the holder.

4. To lower the bottom head back down into the machine frame, use the lever to take the

weight of the head and pull the latch pin out to release the lever arm.

5. Once the tape has been changed or the tapehead has been remounted in the bottom holder

and the guard doors closed, turn the TAPE HOLDER selector switch to DOWN and push

the RESET button to lower the holder back down into the bottom frame.

65-34-5 4/21/10

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 8

Top Tape Head

1. Lower the bottom tape head holder, if raised, pushing the RESET button so that the top

holder will move its lowest position. Turn off the power or open a guard door to shut off the

machine. The top tape roll can be changed in this position.

2. On the top tape head, both the front and rear pins head engage in key-shaped slots. Drop the

head in and then push it back in its holder to engage in retainer clips.

Please consult the tape head manual for instructions on the mounting of tape rolls and the proper

threading of tape through the applicator head.

65-34-5 4/21/10

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 9

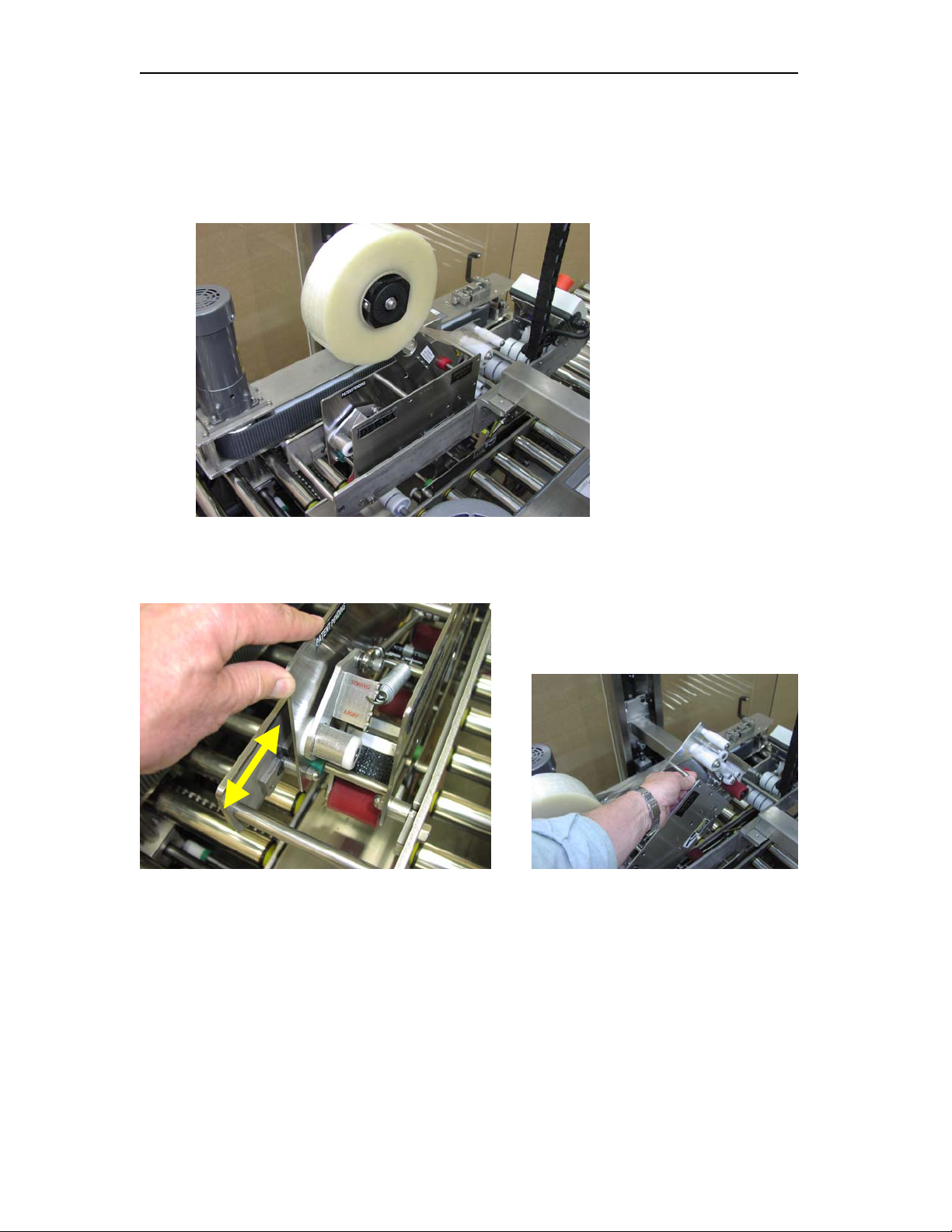

Top Tapehead Downward Force [Pressure Regulator] Adjustment

The top tapehead downward force can be adjusted to provide adequate clamping of the top flaps

and proper taping performance. Too much downward force can cause crushing of the top of the

case or create taping problems. The regulators for the top tape head and conveyor grip are on the

left-hand side of the machine next to the pneumatic air supply and solenoid control valves.

The right hand regulator controls

the top tape head downward force.

To adjust the downward force of the top tapehead, have the machine in ‘Ready’ mode and

use a screwdriver to manually actuate the right-hand end valve on the manifold so that the

pressure indicates on the regulator gauge. Turn the regulator knob to adjust the pressure, it

should be set in the range of 15 psi for average conditions.

65-34-5 4/21/10

BEL 180 SEMI-AUTOMATIC RANDOM TAPE SEALER 10

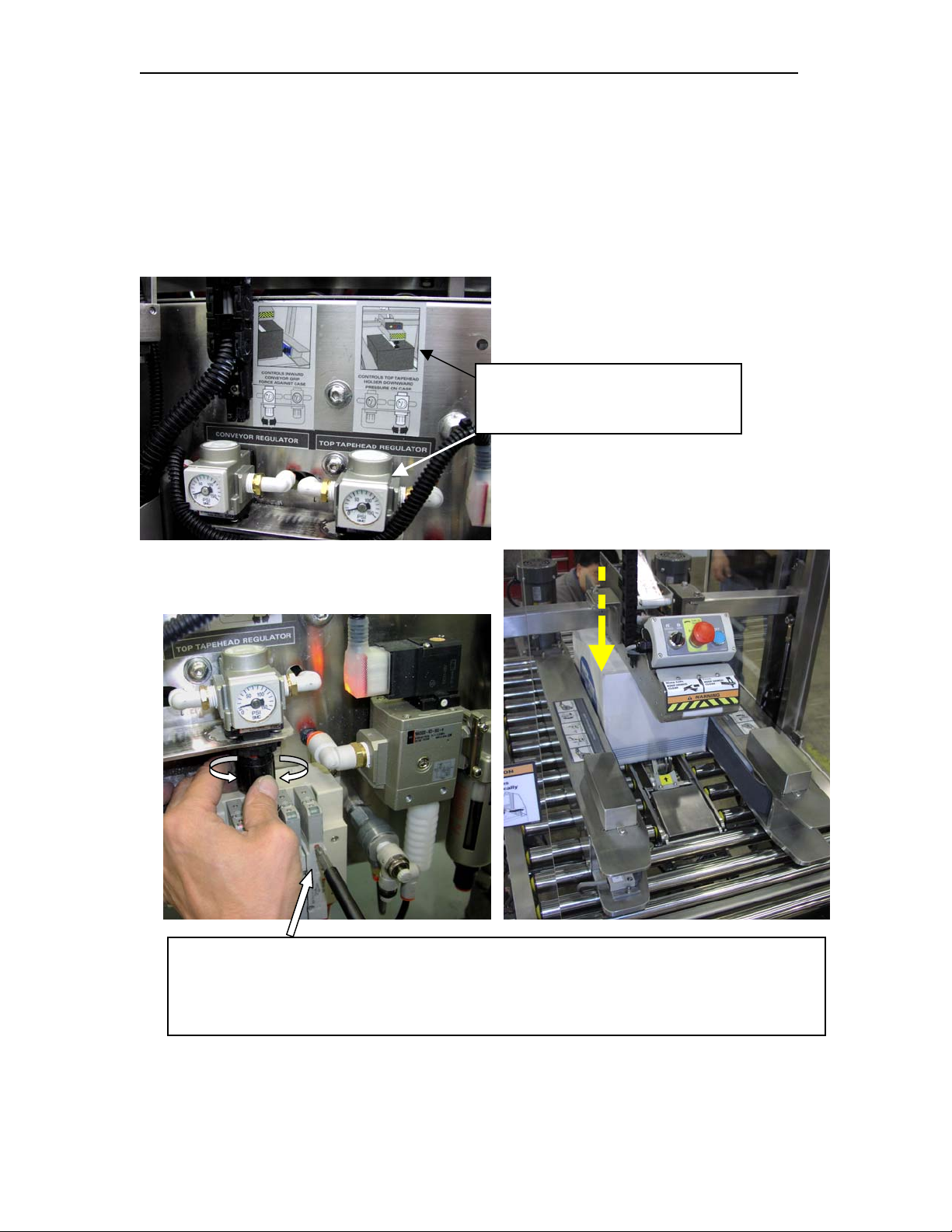

Conveyor Side Force [Pressure Regulator] Adjustment

The force required to center and grip incoming case in the conveyor drive belts may vary

according to the weight of the product. The amount of force exerted by the conveyor belts can be

adjusted by regulating the air pressure in the conveyor case width adjustment mechanism. The

regulator for the width adjustment is on the left-hand side of the machine behind the main control

enclosure at the outfeed end.

Use just enough pressure to center and drive the case effectively. On soft-sided cases, it will

prevent the case and product from being squeezed unnecessarily. The recommended pressure

range is about 40 PSI.

The left hand regulator controls the side

belt conveyor case centering and gripping

force. It should be set in the range of 40

psi for average conditions

65-34-5 4/21/10

Table of contents

Other Wexxar Food Saver manuals