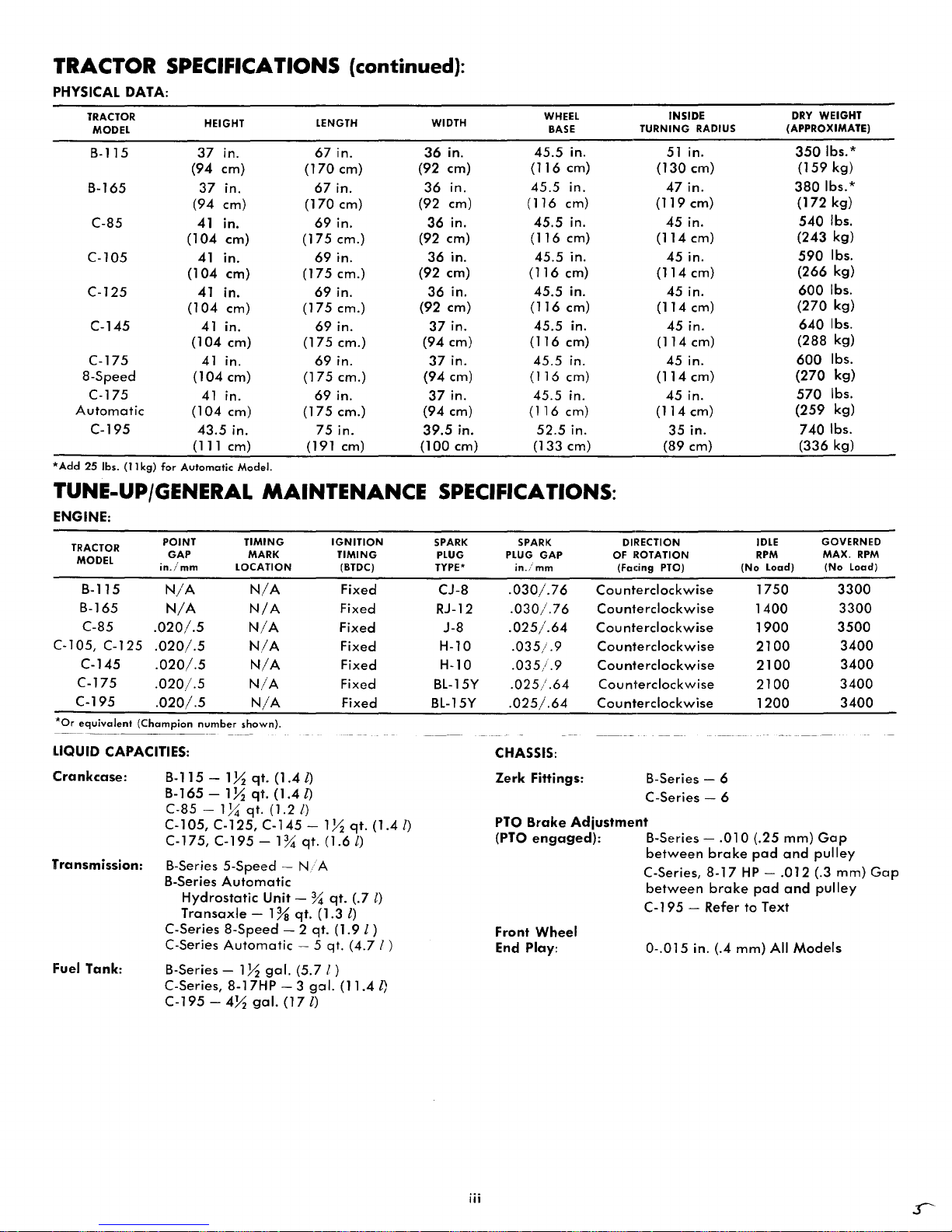

TRACTOR SPECIFICATIONS (continued):

PHYSICAL

DATA:

TRACTOR HEIGHT LENGTH WIDTH WHEEL INSIDE

DRY

WEIGHT

MODEL

BASE

TURNING

RADIUS (APPROXIMATE)

B-115

37

in.

67

in.

36

in.

45.5

in.

51

in.

350

Ibs.*

(94 em)

(170

em) (92 em)

(116

em)

(130

em)

(159

kg)

B-165

37

in.

67

in.

36

in.

45.5

in.

47

in.

380

Ibs.*

(94 em)

(170

em) (92 em) (116 em)

(119

em)

(172

kg)

C-85

41

in.

69

in.

36

in.

45.5

in.

45

in.

540

Ibs.

(104

em) (175 em.) (92 em)

(116

em)

(114

em)

(243

kg)

C-l05

41

in.

69

in.

36

in.

45.5

in.

45

in.

590

Ibs.

(104

em) (175 em.) (92 em)

(116

em)

(114

em)

(266

kg)

C-125

41 in.

69

in.

36

in.

45.5

in.

45

in.

600

Ibs.

(104

em) (175 em.) (92 em)

(116

em)

(114

em)

(270

kg)

C-145

41 in.

69

in.

37

in.

45.5

in.

45

in.

640

Ibs.

(104

em) (175 em.)

(94

em)

(116

em) (114 em)

(288

kg)

C-175

41

in.

69

in.

37

in.

45.5

in.

45

in.

600

Ibs.

8-Speed

(104

em)

(175

em.)

(94

em)

(116

cm)

(114

em)

(270

kg)

C-175

41

in.

69

in.

37

in.

45.5

in.

45

in.

570

Ibs.

Automatic

(104

em)

(175

em.) (94 em)

(116

cm)

(114

em)

(259

kg)

C-195

43.5

in.

75

in.

39.5

in.

52.5

in.

35

in.

7401bs.

(111 em) (191 em) (100 em) (133 em) (89 cm) (336 kg)

*Add

25

Ibs.

(11

kg)

for

Automatic

Model.

TUNE-UP/GENERAL

MAINTENANCE

SPECIFICATIONS:

ENGINE:

TRACTOR

POINT

TIMING

MODEL

GAP

MARK

in./mm

LOCATION

B-115

N/A

N/A

B-165

N/A

N/A

C-85

.020/.5

N/A

C-l05,

C-125

.020/.5

N/A

C-145

.020/.5

N/A

C-175

.020/.5

N/A

C-195

.020/.5

N/A

*Or

equivalent

(Champion

number

shown).

---

--~--

--------

LIQUID

CAPACITIES:

Crankcase:

B-115 - 1X

qt.

(1.4

I)

B-165 -

IX

qt.

(1.41)

C-85 -

1~

qt.

(1.2/)

IGNITION

TIMING

(BTDC)

Fixed

Fixed

Fixed

Fixed

Fixed

Fixed

Fixed

C-l05,

C-125,

C-145

- 1X

qt.

(1.4

I)

C-175, C-195

-1%

qt.

(1.6l)

Transmission:

B-Series

5-Speed

-

N/

A

B-Series

Automatic

Hydrostatic

Unit - %

qt.

(.7 l)

Transaxle

- 1%

qt.

(1.3

I)

C-Series

8-Speed

- 2

qt.

(1.9l)

C-Series

Automatic

- 5 qt.

(4.71

)

Fuel Tank: B-Series - 1X

gal.

(5.7 I )

C-Series,

8-17HP

- 3

gal.

(11.4

I)

C-195

-

4X

gal.

(171)

SPARK

PLUG

TYPE'

CJ-8

RJ-12

J-8

H-l0

H-l0

BL-15Y

BL-15Y

iii

SPARK DIRECTION IDLE GOVERNED

PLUG

GAP

OF ROTATION

RPM

MAX.

RPM

in./mm

(Facing PTO)

(No

Load)

(No

Load)

.030/.76

Cou

nterclockwise

1750

3300

.030/.76

Counterclockwise

1400

3300

.025/.64

Cou

nterclockwise

1900

3500

.035/.9

Counterclockwise

2100

3400

.035/.9

Counterclockwise

2100

3400

.025/.64

Counterclockwise

2100

3400

.025/.64

Counterclockwise

1200

3400

CHASSIS:

Zerk

Fittings: B-Series - 6

C-Series - 6

PTO

Brake

Adjustment

(PTO

engaged):

B-Series -

.010

(.25

mm)

Gap

between

brake

pad

and

pulley

Front

Wheel

End Play:

C-Series,

8-17

HP

-

.012

(.3

mm)

Gap

between

brake

pad

and

pulley

C-195 -Refer

to

Text

0-.015

in. (.4

mm)

All

Models