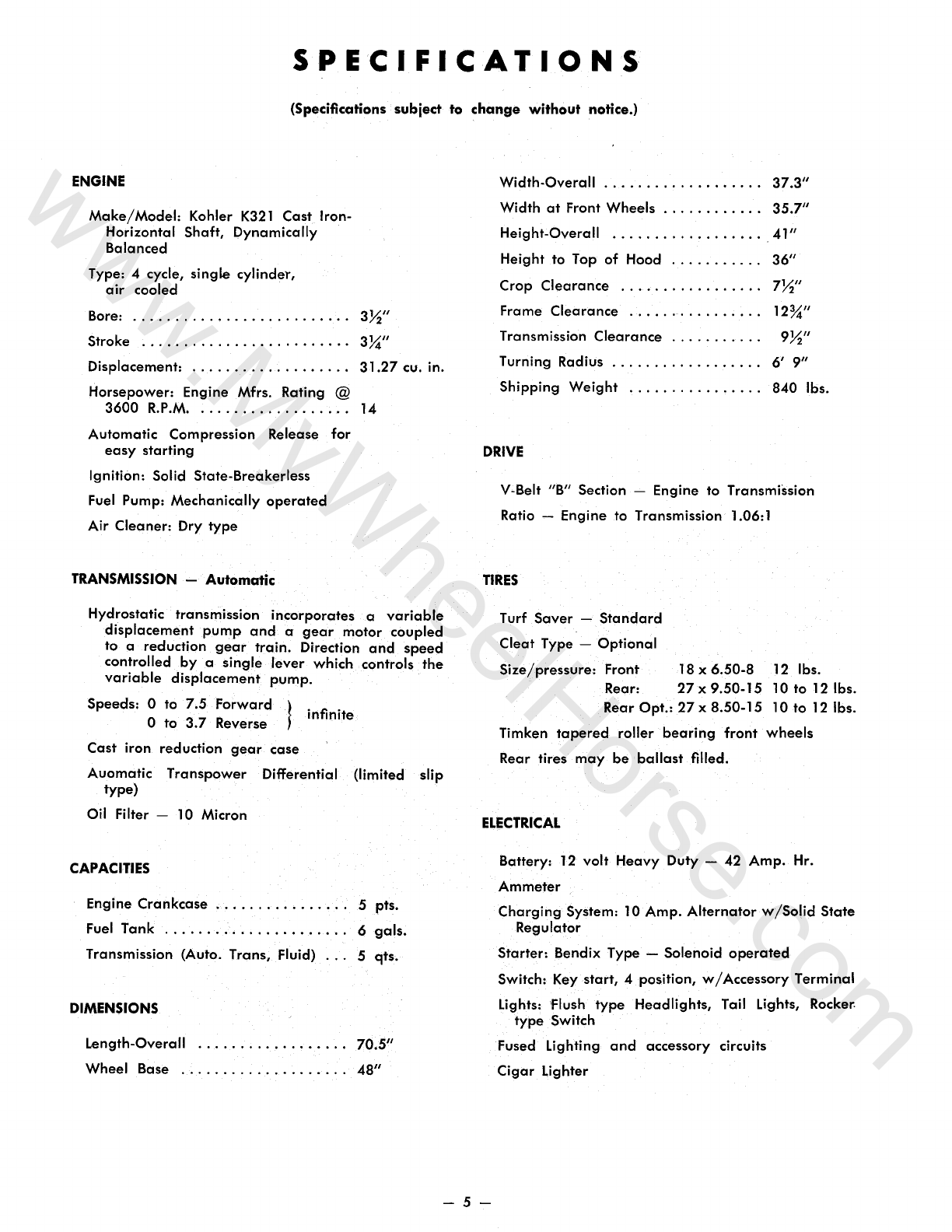

SPECIFICATIONS

(Specifications subject to

change

without

notice.)

ENGINE

Make/Model:

Kohler

K321

Cast

Iron-

Horizontal

Shaft,

Dynamically

Balanced

Type: 4 cycle, single cylinder,

air

cooled

Bore:

..........................

3X"

Stroke

.........................

3X"

Displacement:

...................

31.27

cu. in.

Horsepower: Engine Mfrs. Rating @

3600

R.P.M

•..................

14

Automatic

Compression Release for

easy

starting

Ignition: Solid State-Breakerless

Fuel Pump: Mechanically

operated

Air Cleaner: Dry

type

TRANSMISSION

-Automatic

Hydrostatic transmission

incorporates

a

variable

displacement

pump

and

a

gear

motor

coupled

to

a reduction

gear

train.

Direction

and

speed

controlled

by

a single lever which controls

the

variable

displacement

pump.

Speeds:

0 to 7.5

Forward

} infinite

o

to

3.7

Reverse

Cast

iron reduction

gear

case

Auomatic

Transpower

Differential (limited slip

type)

Oil Filter -10 Micron

CAPACITIES

Engine

Crankcase

5 pts.

Fuel Tank

......................

6

gals.

Transmission (Auto. Trans, Fluid)

..

, 5 qts.

DIMENSIONS

Length-Overall

70.5"

Wheel Base

....................

48"

Width-Overall

...................

37.3"

Width

at

Front Wheels . . . . . . . . . .

..

35.7"

Height-Overall

..................

41"

Height

to

Top

of

Hood

...........

36"

Crop

Clearance

.................

7X"

Frame

Clearance

................

12%"

Transmission

Clearance

...........

9X"

Turning Radius

..................

6'

9"

Shipping

Weight

................

840

Ibs.

DRIVE

V-Belt "B" Section -Engine to Transmission

Ratio -Engine to Transmission 1.06:1

TIRES

Turf

Saver

-

Standard

Cleat

Type -

Optional

Size/pressure:

Front 18 x 6.50-8 12 Ibs.

Rear:

27

x

9.50-15

10

to

12 Ibs.

Rear Opt.:

27

x

8.50-15

10

to

12 Ibs.

Timken

tapered

roller

bearing

front

wheels

Rear tires

may

be

ballast

filled.

ELECTRICAL

Battery: 12 volt

Heavy

Duty -42

Amp.

Hr.

Ammeter

Charging

System: 10

Amp.

Alternator

w

/Solid

State

Regulator

Starter:

Bendix Type -Solenoid

operated

Switch: Key

start,

4 position, w/ Accessory Terminal

Lights:

flush

type

Headlights, Tail Lights, Rocker.

type

Switch

Fused Lighting

and

accessory circuits

Cigar

Lighter

-5-