Page 2

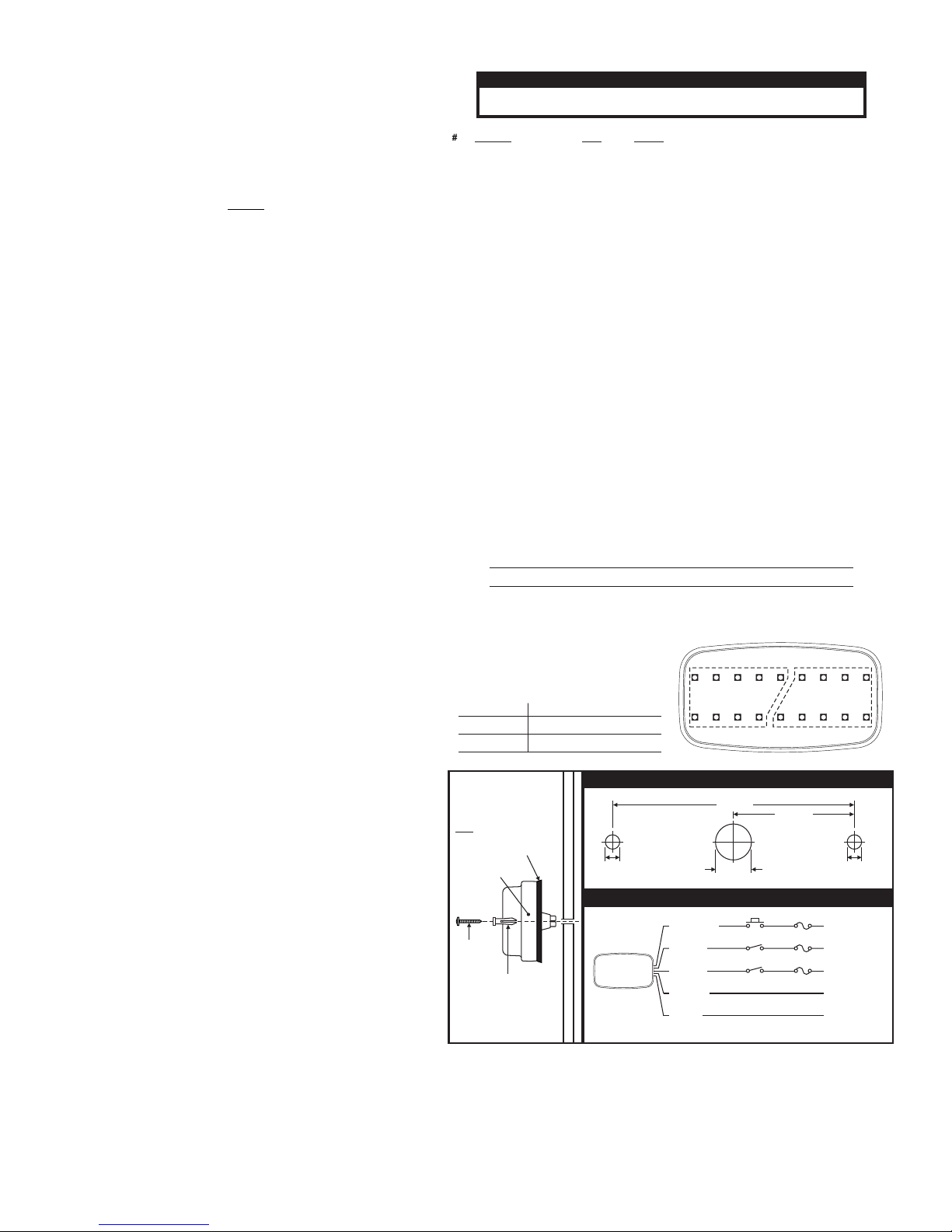

To +12VDC

To +12VDC

To +12VDC

To Ground

WHT/VIO

LED#1

LED#2

BLACK

GREY SYNC

1A Fuse

3A Fuse

3A Fuse

SP/ST

SP/ST

MOM. SW

M6 Lighthead

(Split)

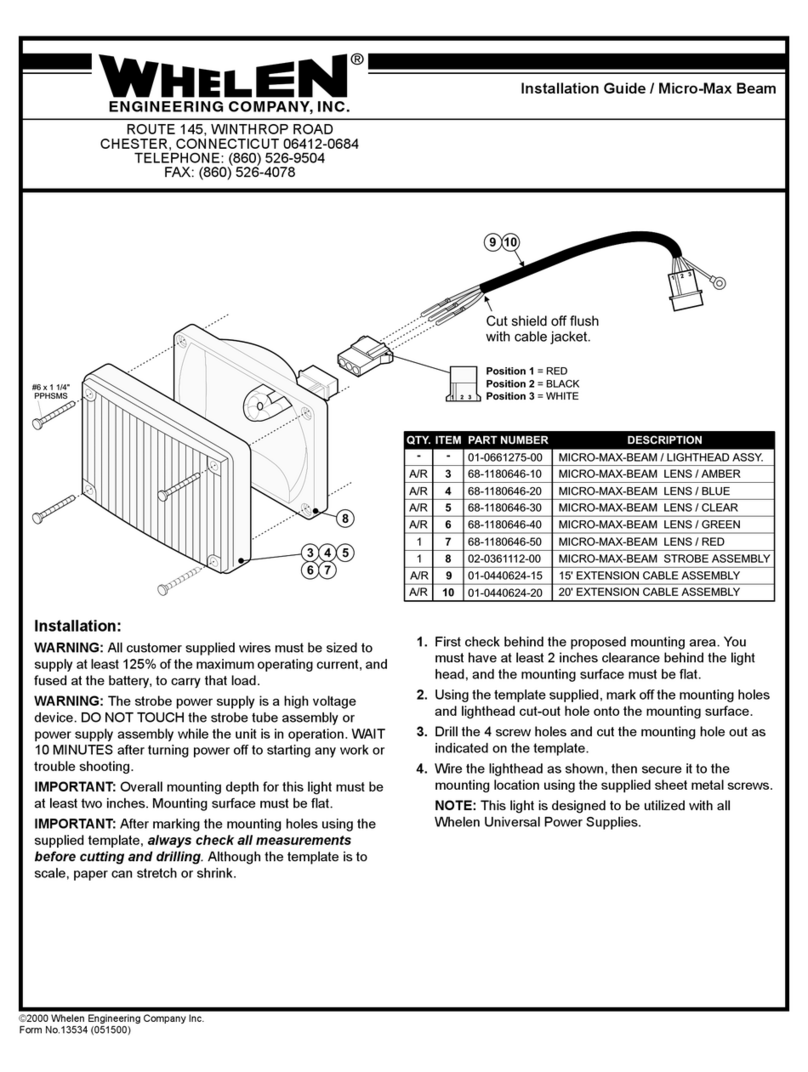

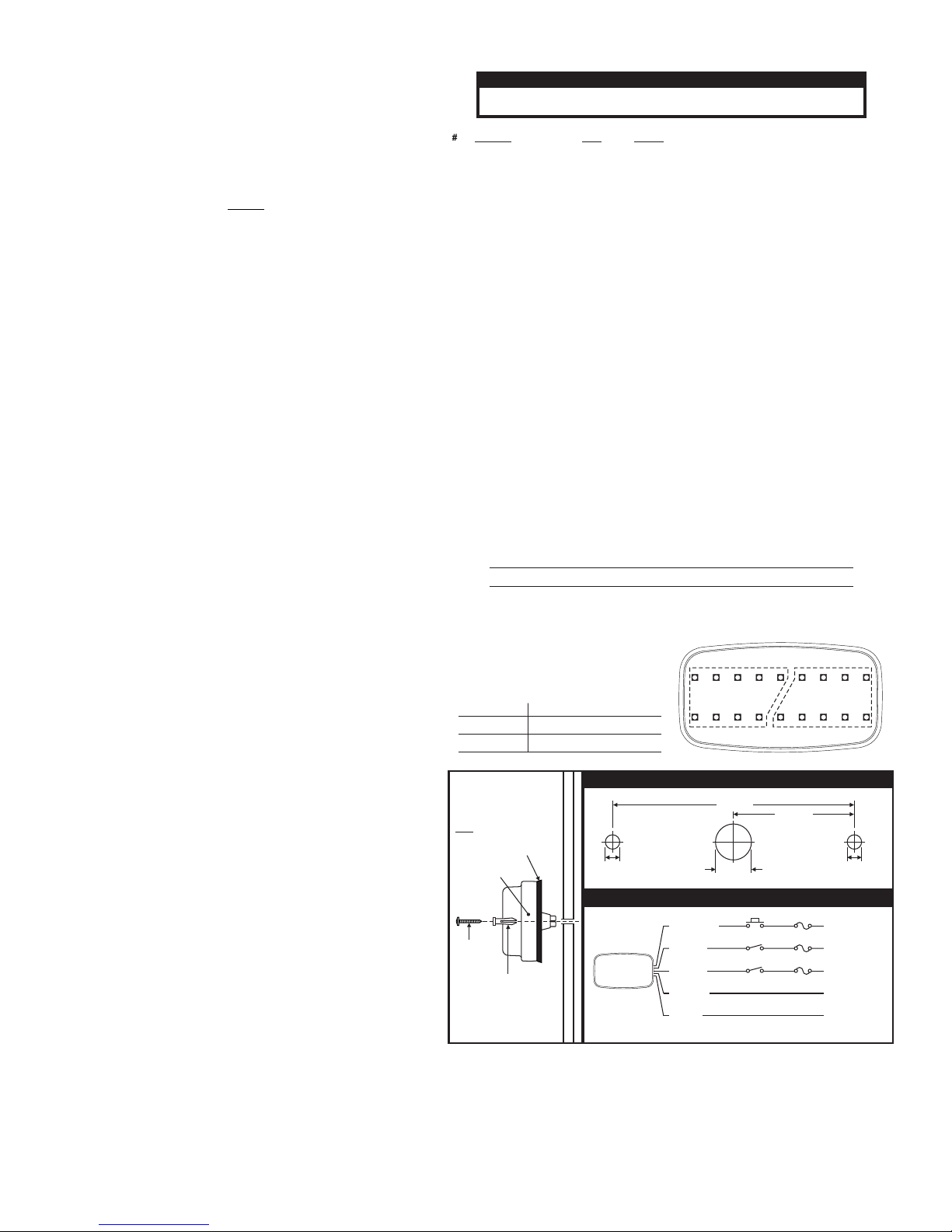

5.420" 2.710"

0.25"

0.625"

0.25"

M

O

U

N

T

I

N

G

S

U

R

F

A

C

E

#8 x 1"

Sheet Metal

Screw

M6 Assembly

Slotted Hole

Screw Grommet

(note orientation)

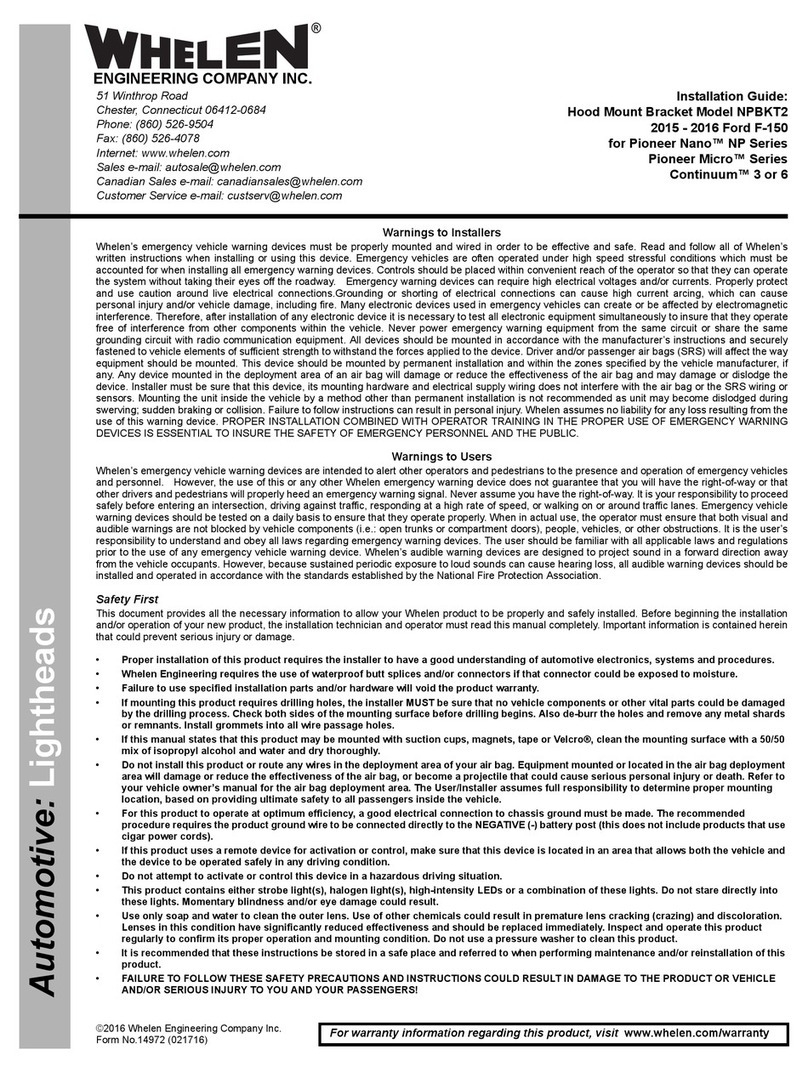

MOUNTING DIMENSIONS

WIRING DIAGRAM

Gasket Note - Use the

rubber gasket on flat,

smooth surfaces .

For diamond plate, use

the adhesive-backed

gasket (applied to the

rear of the lighthead).

only

only

ITALIC = SYNCBOLD = California Title XIII Compliant L/R=Left/Right

Sequences Operation of LED sets

Left to Right

Solid

12

All On All Off

Alternates with

Alternates with

M6 Sequencing & Phasing: The M6

lighthead has 2 sets of 9 LEDs. These

sets cycle through the sequences

shown below:

12

NOTE: Phase 1 and Phase 2 patterns are visually indistinguishable from each other

unless two or more lightheads are SYNC'd together.

Pattern

Seq.

Phase

1 SignalAlert™ CAL L/R PH.1

2

30 SingleFlash 60 Solid

SignalAlert CAL L/R PH.2

3 SignalAlert CAL Solid PH.1

4 SignalAlert CAL Solid PH.2

9 DoubleFlash 75 L/R PH.1

10 DoubleFlash 75 L/R PH.2

11 DoubleFlash 75 Solid PH.1

12 DoubleFlash 75 Solid PH.2

13 SingleFlash 75 L/R PH.1

14 SingleFlash 75 L/R PH.2

15 SingleFlash 75 Solid PH.1

16 SingleFlash 75 Solid PH.2

25 PingPong™ 75 L/R PH.1

26 PingPong 75 L/R PH.2

27 PingPong 75 Solid PH.1

28 PingPong 75 Solid PH.2

29 SingleFlash 60 L/R

31 SingleFlash 90 L/R

32 SingleFlash 90 Solid

33 SingleFlash 120 L/R

5 CometFlash®75 L/R PH.1

6 CometFlash 75 L/R PH.2

7 CometFlash 75 Solid PH.1

8 CometFlash 75 Solid PH.2

17 ComAlert™ 75 L/R PH.1

18 ComAlert 75 L/R PH.2

19 ComAlert 75 Solid PH.1

20 ComAlert 75 Solid PH.2

21 LongBurst™ 75 L/R PH.1

22 LongBurst 75 L/R PH.2

23 LongBurst 75 Solid PH.1

24 LongBurst 75 Solid PH.2

34 SingleFlash 120 Solid

61 SignalAlert w/Steady

62 SingleFlash 75 w/Steady

35 SingleFlash 300 L/R

36 SingleFlash 300 Solid

37 DoubleFlash 150 L/R

38 DoubleFlash 150 Solid

39 ComAlert™150 L/R

40 ComAlert 150 Solid

41 ActionFlash™50 L/R

42 ActionFlash 50 Solid

43 ActionFlash™150 L/R

44 ActionFlash 150 Solid

45 ModuFlash™ L/R

46 ModuFlash Solid

60 ActionScan™

47 DoubleFlash 120 L/R

48 DoubleFlash 120 Solid

49 PingPong™120 L/R

50 PingPong 120 Solid

51 TripleFlash™75 L/R

52 TripleFlash 75 Solid

53 TripleFlash 120 L/R

54 TripleFlash 120 Solid

55 Action SF60/120 L/R

56 Action SF60/120 Solid

57 Action SF120/TF75 L/R

58 Action SF120/TF75 Solid

59 CalScan™

63 SignalAlert™ Steady

64 Steady

Installation and Wiring:

Caution: Permanent mounting of this product will require drilling.

It is absolutely necessary to make sure that no other vehicle

components could be damaged by this process. Check both sides

of the mounting surface before starting. If damage is likely, select a

different location.

WARNING! All customer supplied wires that connect to the positive

terminal of the battery must be sized to supply at least 125% of the

maximum operating current and FUSED at the battery to carry that

load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!

NOTE: The color of the Positive Wire is determined by the color of

the LED. In this manual, RED is used as a reference color.

1. Using the dimensions below, mark the mounting and wire hole

locations onto the proposed mounting surface. Drill two, .250"

diameter mounting holes and a .625" (minimum) wire access hole into

the mounting surface.

2. Place the appropriate gasket into position on the rear of the M6

assembly (see Gasket Note). Insert the slotted hole screw grommet

through the mounting holes on the M6/Gasket assembly so that it is

flush with the lens.

3. Feed the M6 wires through the wire access hole in the mounting

surface. Press the M6/Gasket/Grommet assembly onto its mounting

location so that it is flat against the mounting surface.

4. With the assembly in position and using the hardware provided,

tighten the mounting screws until the lighthead assembly is drawn

firmly against the mounting surface. A torque value of 12 in-lb. (max.)

is typically required to achieve this. DO NOT OVER TIGHTEN!

5. Using appropriately sized wires (minimum 18 AWG), extend the M6

wires to their designated connections. Refer to the diagram below for

wiring and fusing information.

Operation:

Flash Mode / RED:

Apply +12V to the RED wire to activate the lighthead in “flash mode”.

With flash mode activated, you may change the flash pattern using Scan-

Lock™.

SYNC / GREY

To SYNC two lightheads, configure both lightheads to display the same

Phase 1 (Simultaneous) pattern. Turn the power off and connect the

GREY wire from each lighthead together. When the lightheads are acti-

vated their patterns will be synchronized. To configure two lightheads to

alternate their patterns, advance the pattern of either lighthead to Phase

2 (Alternating) of the current pattern.

Scan-Lock™ / WHT/VIO / Flash Pattern Selection:

This feature allows the user to select from several available flash

patterns. The lighthead must be switched on for Scan-Lock™ to work.

TO CYCLE THROUGH ALL PATTERNS: Apply positive voltage to the

WHT/VIO wire for less than 1 second and release. To cycle backward

through patterns apply positive voltage to the WHT/VIO wire for over 1

second and release.

TO SET A PATTERN AS DEFAULT: Allow the pattern to run for more

than 5 seconds. The lighthead will flicker slightly when the pattern locks

in. This flicker may be difficult to see with some patterns. The lighthead

will now display this pattern when activated.

TO RESET TO THE FACTORY DEFAULT PATTERN: Turn off power.

While applying positive voltage to the WHT/VIO wire, turn power on. This

will reset the lighthead to it’s factory default flash pattern.

IMPORTANT! It is the responsibility of the installation technician to

make sure that the installation and operation of this product will not

interfere with or compromise the operation or efficiency of any

vehicle equipment!

CAUTION! DO NOT LOOK DIRECTLY AT THESE LED’S WHILE THEY ARE ON.

MOMENTARY BLINDNESS AND/OR EYE DAMAGE COULD RESULT!

IMPORTANT WARNING!