Xcavator

Operating Instructions

2

Intended Purpose

The Whip Mix Xcavator is designed to automatically remove

95% of the volume of investment mold material surrounding

pressed ceramic restorations where manual divestment would

typically be done. When used as directed, the unit will

significantly shorten the total process time required to go from

press oven removal to pattern retrieval. The unit can be run

Grounding

The high velocity flow of glass beads across plastic or

metal surfaces will charge the beads and the surfaces they

flow over. Great pains have been taken to ground every

component in the Xcavator to insure equalization of static

electrical charges. The power cord and the outlet the unit

is plugged into must have 3 prongs to insure the presence

of the earth ground which is vital to the prevention of static

electrical charge buildup. If, for any reason, you receive a

static electrical shock from any part of the equipment, you

should verify the integrity of the grounded outlet the unit is

plugged into, or call an electrician. Operating the unit

ungrounded can result in painful shocks to the operator

and damage to the electronics of the unit itself.

Never cut the ground stud off the power cord or plug

the unit into a 2 lead extension cord or outlet.

Dry Air Supply

All compressed air condenses moisture in the air lines as

a result of the physics of gas compression. This moisture

can accumulate in low areas of the air piping even if there

is a master air dryer at the compressor.

It is recommended that a cartridge type dryer be placed

just before the air regulator of the unit. If moist air enters

the unit it will collect in the reservoir and cause clumping

of beads and disrupt the critical air/bead ratio needed

for consistent divestment. It can also plug up either the

reservoir output orifice or the bead/air injector inside

the injector block and cause inconsistent divestment.

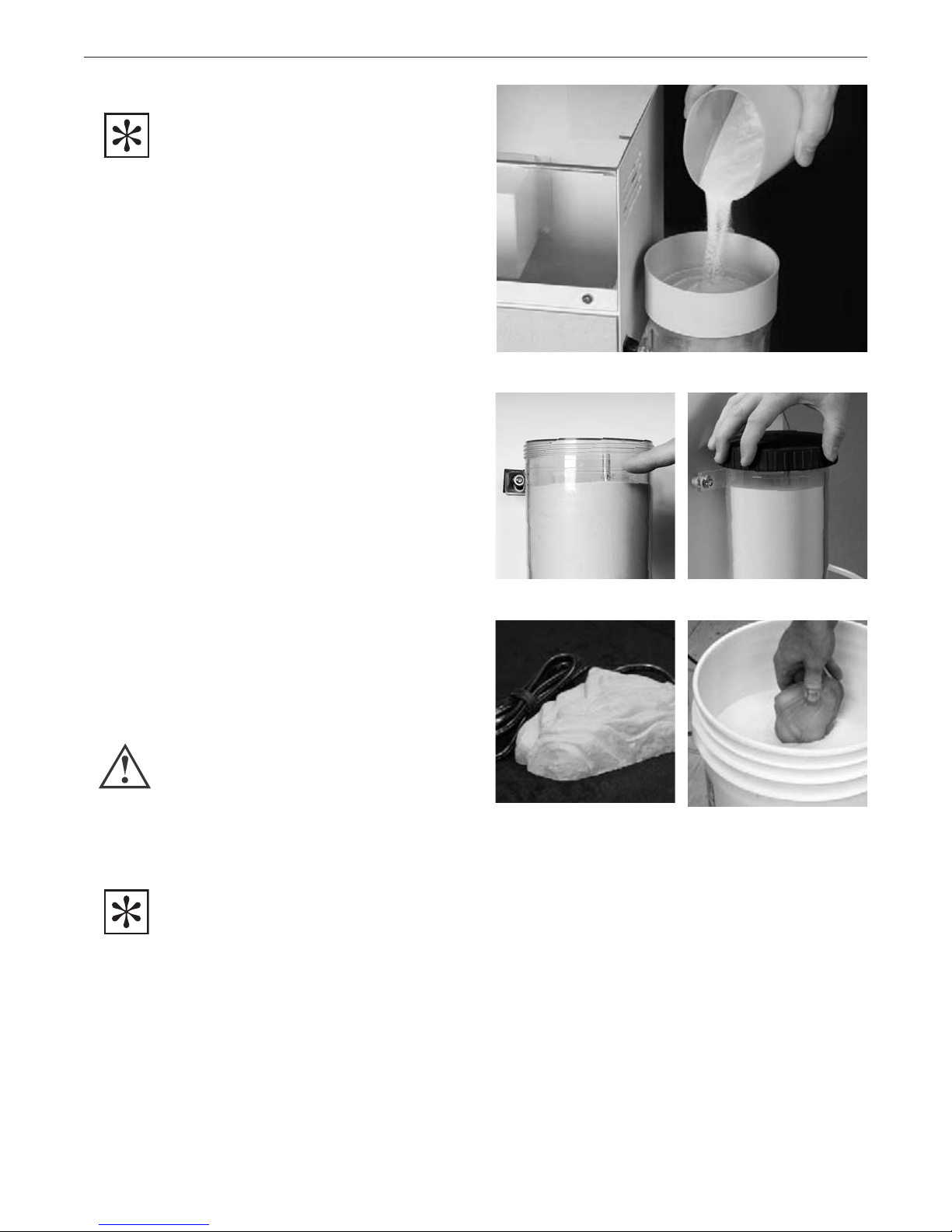

Dry Bead Supply

The strainer supplied with the Xcavator serves two purposes;

(1) it eliminates clumped beads and foreign debris which

could clog the bead transport system, (2) it validates/

invalidates the dryness of the beads. If the beads will not

pass through the strainer without tapping or shaking the

strainer, then they are too moist to be transported reliably.

A five watt heater is supplied with the Xcavator to be

placed fully submerged in the bead storage container. It

will raise the temperature of the beads to about 5°above

the room temperature. This gentle warming will drive off

any moisture the beads might accumulate and insure they

will transport reliably.

Treat Pressurized Components With Care

Never strike the bead jar or pull on the connecting air

tubing while the system is pressurized. This can result in

cracking the plastic jar or wind up spraying glass beads or

plastic debris around the area and pose a safety hazard.

Particulate Exposure

Never open the cabinet door while a divestment cycle is

in progress. The exhaust system will pull the dust cloud

towards the rear of the cabinet, but air conditioning/heating

convection currents in the room could cause a portion

of the dust cloud to escape into the room and pose a

possible health risk.

Handling of Hot Investment Molds

Always use laboratory tongs to handle hot investment molds

and cautiously test the temperature of divested molds before

you attempt to remove divested molds from the cabinet.

Exhaust Flow Volume

The built-in vacuum sensor will prohibit divesting unless

the vacuum flow is sufficient to remove the airborne dust

rapidly. If you are having dust cloud removal issues check

your vacuum unit or central vacuum flow to ensure removal

of the fine dust.

Divesting Media Composition

and Particle Sizes

Use only 50–100 micron glass beads with the Xcavator

for the following reasons:

1. Other material types may be harder than glass

beads and damage the porcelain work product.

2. Other material sizes may alter the depth of cut,

and/or the cut channel width.

unattended and will alert the operator when an investment mold

is divested to allow efficient processing and labor usage.

The unit employs state of the art robotic precision to

ensure consistent material removal time after time.

The Xcavator is easy to operate, ergonomically friendly

and compact enough to earn its place on a work surface

in the casting room.

Important Topics for Safe, Reliable Operation

IMPORTANT NOTE: THE XCAVATOR PRODUCT HAS BEEN

EXHAUSTIVELY TESTED WITH WHIP MIX BRAND 50 MICRON GLASS

BEAD MEDIA. FOR BEST AND MOST RELIABLE DIVESTING RESULTS

WE STRONGLY RECOMMEND YOU USE WHIP MIX BRAND BEADS.

WHIP MIX BEADS FLOW MORE RELIABLY, AND ARE LESS PRONE

TO CLUMPING DURING HIGH HUMIDITY CONDITIONS.

THE USE OF ALUMINUM OXIDE (ALOX), BEADS IS NOT RECOMMENDED

FOR USE WITH THE XCAVATOR. ALOX BEADS WILL POTENTIALLY

CAUSE DAMAGE TO YOUR PORCELAIN BECAUSE THEY ARE HARDER

THAN THE PORCELAIN. ALOX WILL ALSO CAUSE PREMATURE

WEARING OUT OF THE QUARTZ NOZZLE.