TABLE OF CONTENTS

VESSI™ FERMENTOR & DISPENSER SAFETY ��������������������������������������������������������������3

Important Safeguards ����������������������������������������������������������������������������������������������������4

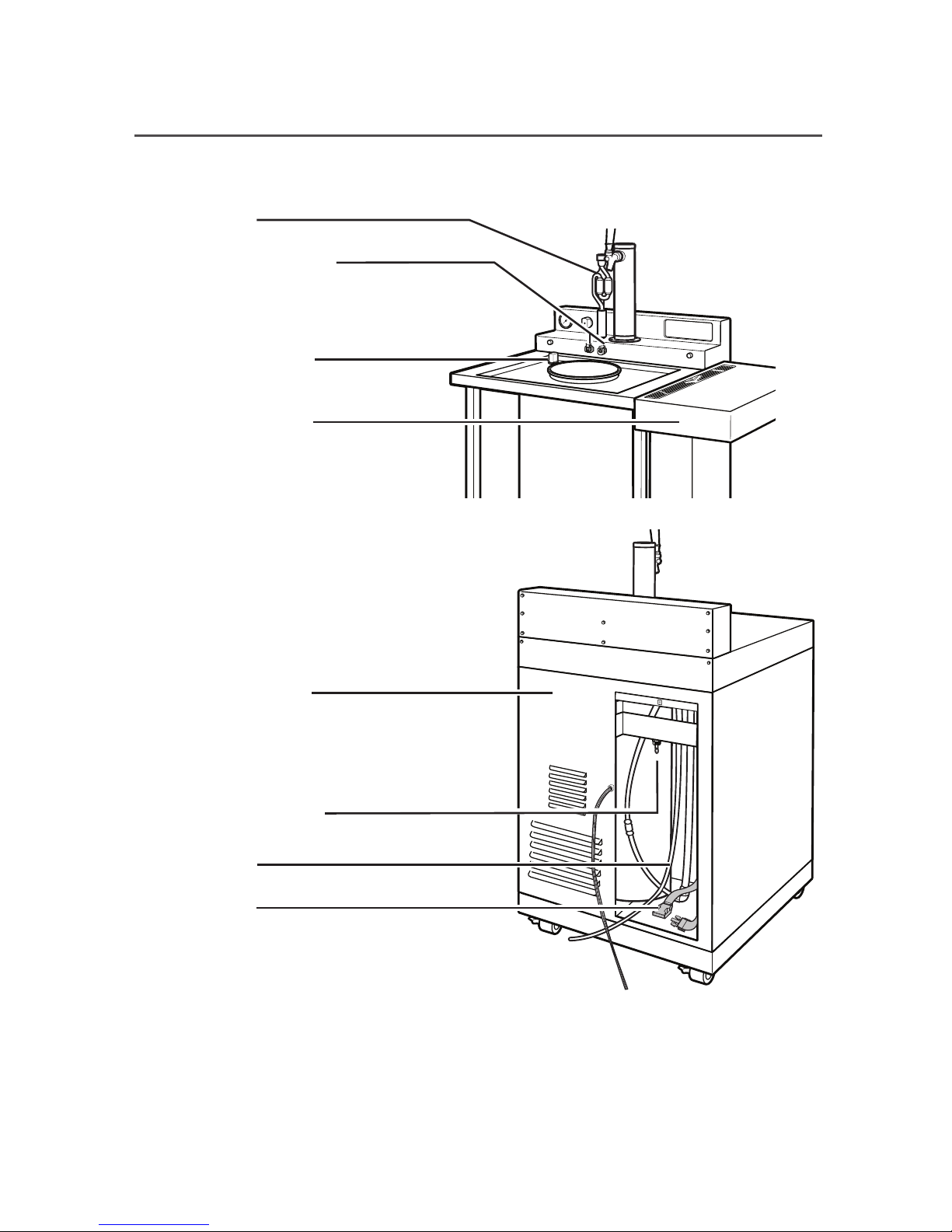

VESSI™ FERMENTOR & DISPENSER OVERVIEW���������������������������������������������������������5

Parts and Features���������������������������������������������������������������������������������������������������������5

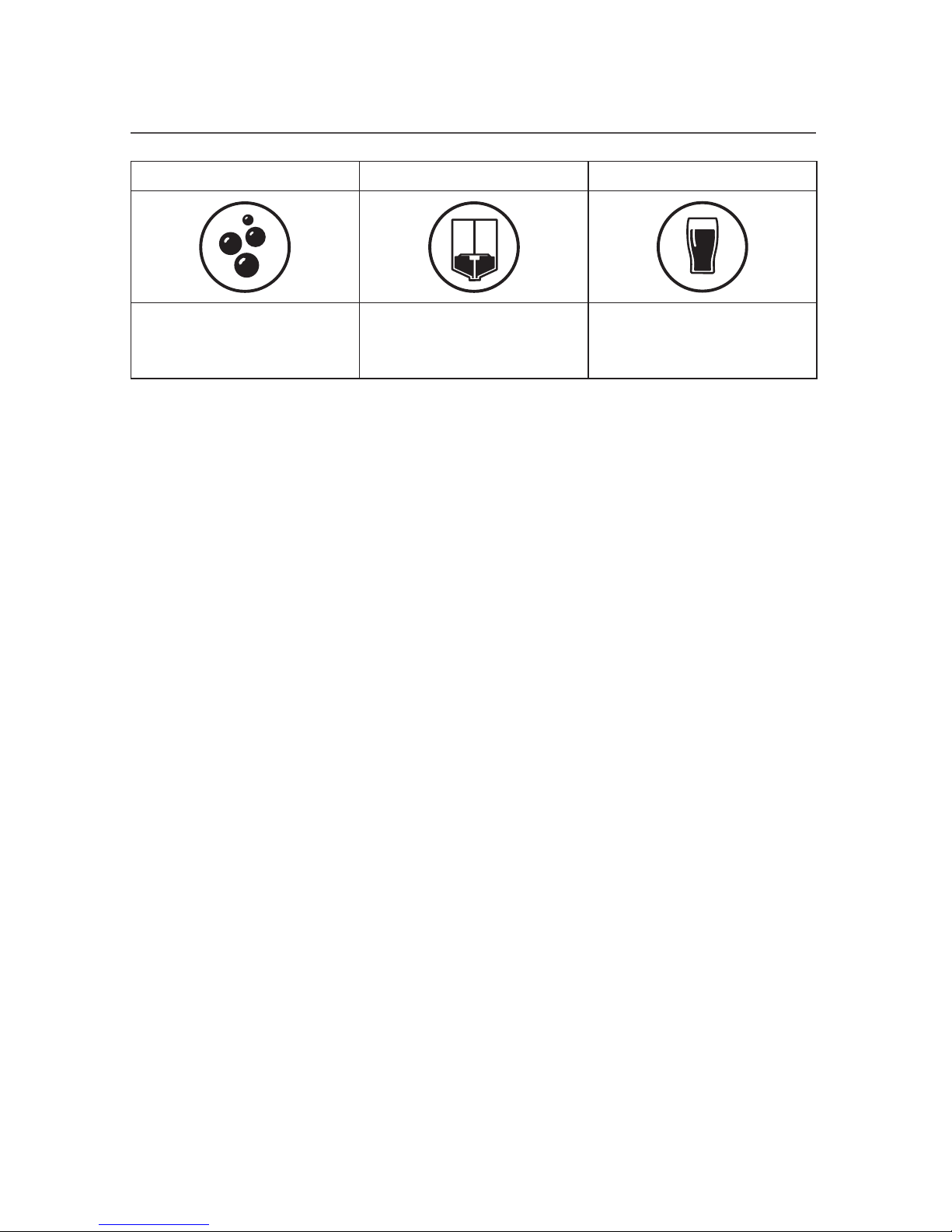

From Pitch to Pour In as Little as 7 Days ����������������������������������������������������������������������7

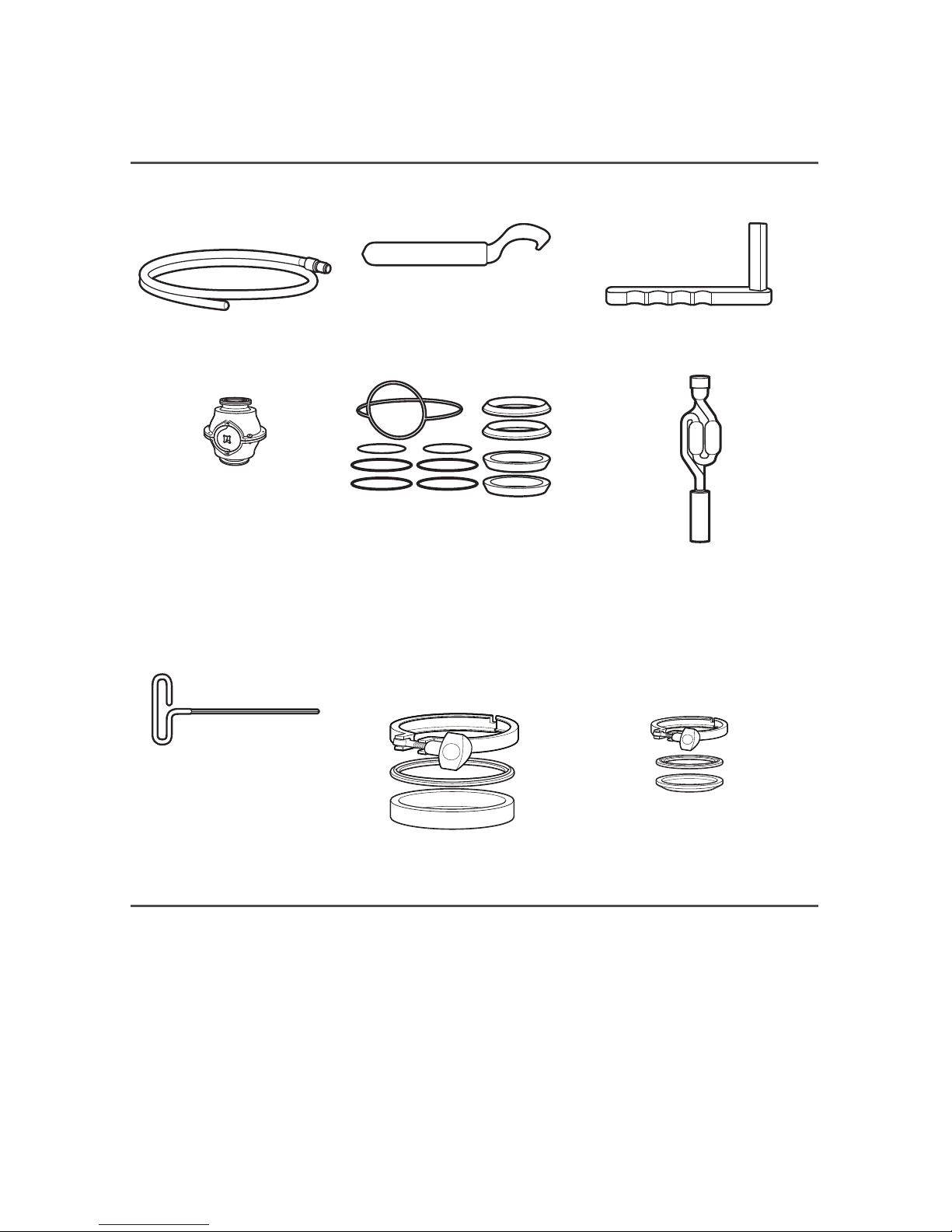

VESSI™ FERMENTOR & DISPENSER PARTS AND ACCESSORIES ���������������������������8

Tools and Parts Provided�����������������������������������������������������������������������������������������������8

Tools Needed�����������������������������������������������������������������������������������������������������������������8

Parts and Accessories Needed �������������������������������������������������������������������������������������9

PRODUCT DIMENSIONS �������������������������������������������������������������������������������������������������10

ELECTRICAL REQUIREMENTS ��������������������������������������������������������������������������������������10

LOCATION REQUIREMENTS�������������������������������������������������������������������������������������������11

SETTING UP YOUR VESSI™ FERMENTOR & DISPENSER ����������������������������������������12

Unpacking �������������������������������������������������������������������������������������������������������������������12

Installing the CO2Tank�������������������������������������������������������������������������������������������������12

Preparing Vessi™ Fermentor & Dispenser for Use������������������������������������������������������16

CLEANING AND SANITIZING YOUR VESSI™ FERMENTOR & DISPENSER ������������17

Disassembling the Sediment Removal System (SRS)�������������������������������������������������17

Remove Heavy Solids From Vessel �����������������������������������������������������������������������������20

Thorough Cleaning of Vessel and Dispensing Lines����������������������������������������������������21

Cleaning the Beverage Lines���������������������������������������������������������������������������������������22

Rinsing �������������������������������������������������������������������������������������������������������������������������23

Sanitizing ���������������������������������������������������������������������������������������������������������������������24

Sediment Removal System (SRS) Assembly���������������������������������������������������������������25

Pressure/Leak Testing��������������������������������������������������������������������������������������������������28

USING YOUR VESSI™ FERMENTOR & DISPENSER ���������������������������������������������������29

Preparing for Fermentation �����������������������������������������������������������������������������������������29

Setting Fermentation Pressure ������������������������������������������������������������������������������������31

Setting the Temperature ����������������������������������������������������������������������������������������������33

Monitoring the Fermentation Process �������������������������������������������������������������������������33

Liquid Injection System (LIS) ���������������������������������������������������������������������������������������33

Sediment Removal�������������������������������������������������������������������������������������������������������35

Specific Gravity Measurement�������������������������������������������������������������������������������������36

Clarification������������������������������������������������������������������������������������������������������������������37

Adding Ingredients/Stirring Beverage��������������������������������������������������������������������������37

Dispensing, Bottling, and Kegging ������������������������������������������������������������������������������38

Accessories and Supplies �������������������������������������������������������������������������������������������39

WARRANTY������������������������������������������������������������������������������������������������������������������������40