Elect rkal

Requirements

Electrical Shock Hazard

.Eleclrical ground is required on

this appliance.

*Improperconnection of the

equipment-grounding

conductor can result in

electrical shock.

l

Check with a qualrfied

electrician if you ore in doubt

as to whether the applrance is

properly grounded. Do Not

modify the power supply cord

plug. If it will not frt. have a

proper outlet installed by a

qualified electrician.

l

Do Not use an extension cord

with this appliance. Such use

may result in a fire, electrical

shock or other personal injury

l

Do Not have a fuse in the neutral

or grounding circuit A fuse in

the neutral or aroundina circuit

could result in& elect&al

shock.

Failure to follow these instructions

could result in an electrical

shock.

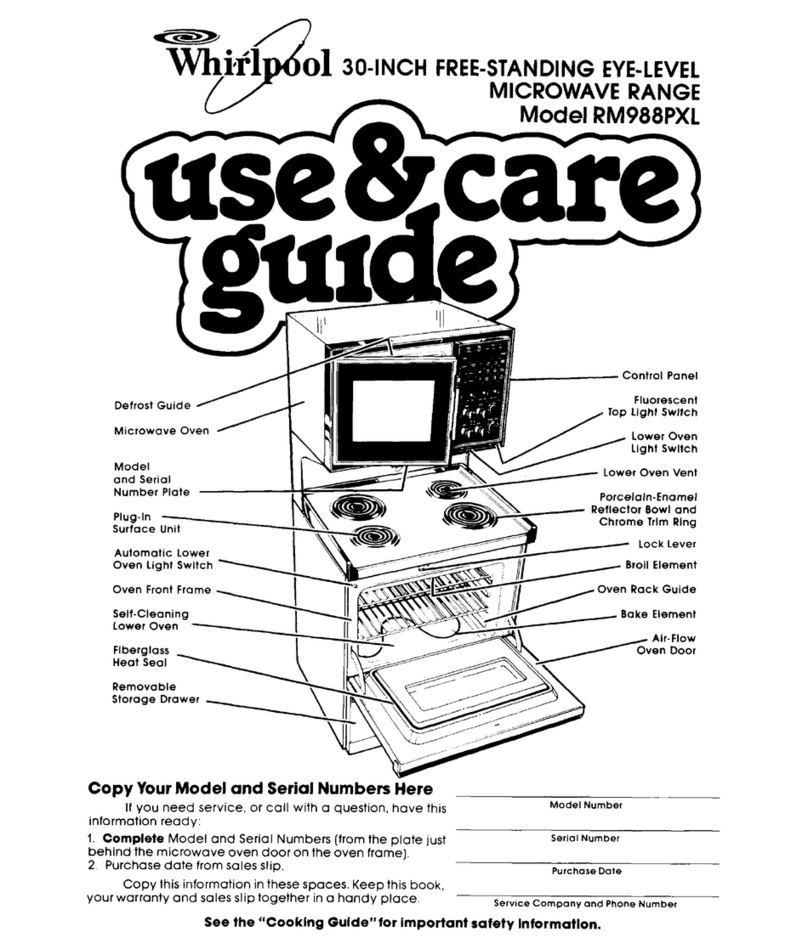

A 120~volt. M)-Hz. AC only. 15 amp,

fused electrical supply is required. A

timedelay fuse or circuit breaker is

recommended. It is recommended that

a separate circuit serving only Ihis

appliance be provided.

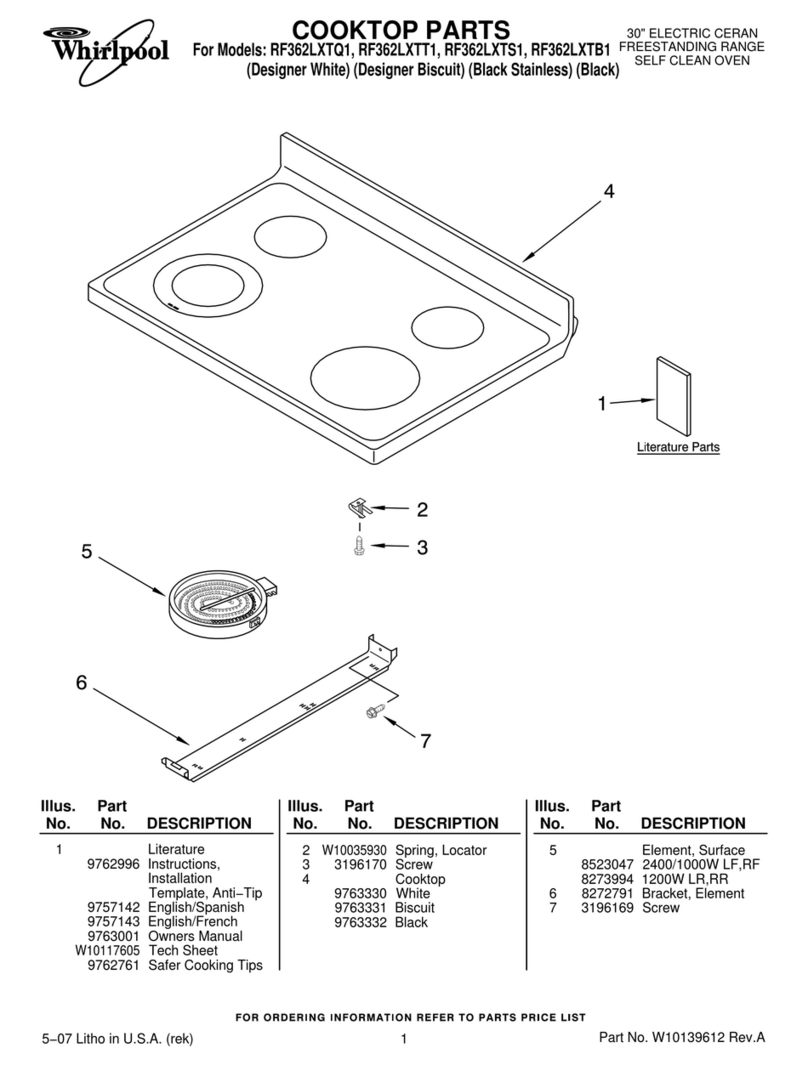

A wiring diagram is included in literature

package. The wiring diagram is also

located on the back of the range.

Recommended

Grounding

Method

Do NOT. UNDER ANY CIRCUMSTANCES.

REMOVE THE POWER SUPPLY CORD

GROUNDING PRONG.

For your penonol tiet~. this appliance

must be grounded. This appliance is

equipped with a power supply cord

having a Sprang graundlng plug. To

minimize possible shock hazard. the

cord must be plugged into a mating.

3-pmna. omundino tvDe wall

recept&%. gmur& in accordance

with the National Electrical Cdde.

ANSVNFPA 70- latest edition.*’ and all

local codes and ordinanc&(See Figure

l,] If a mating wall receptacle is not

available. it is the personal responsibility

and obligation of the customer to have

a pmperly grOUnded,

3-prong wall Qxow

receptacle wwrding him

..- A

Temporary v

Grounding Method

DO NOT, UNDERANYCIRCUMSTANCES.

REMOVE THE POWER SUPPLY CORD

GROUNDING PRONG.

&ctrtcal ground Is required on thls

appliance

If changing and properly grounding

the wall receplacle ISImpaosslble and

where local codes permit (consull your

elecirical ~nspeclor). a lemp3rary

PANEL B

adaptor may be plugged inio ihe

existing 2-prong wall receptacle lo mate

with the J-prong power supply cord.

If this is done. you must connect a

separate capper grounding wire (No. 18

minimum] to a grounded cold water

pipe by means of a clamp and then to

the external Qrounding connector Screw

Do not ground to a gas supply

hot water pipe. Co not connect

electrical supply until appliance i

permanently grounded

See Figure 2.

Grounded cold water pipe musi

have metal conlinuity to electrica

ground and not be interrupted

by plastic. rubber or otherelectri

insulating cOnnecton such as

hoses. fittings. washers or gaskets

(including water meter or pump).

Any electrical Insulating connect

should be jumped as shown with

length of No. 4 wire securely clamaed

to bare metal at both ends

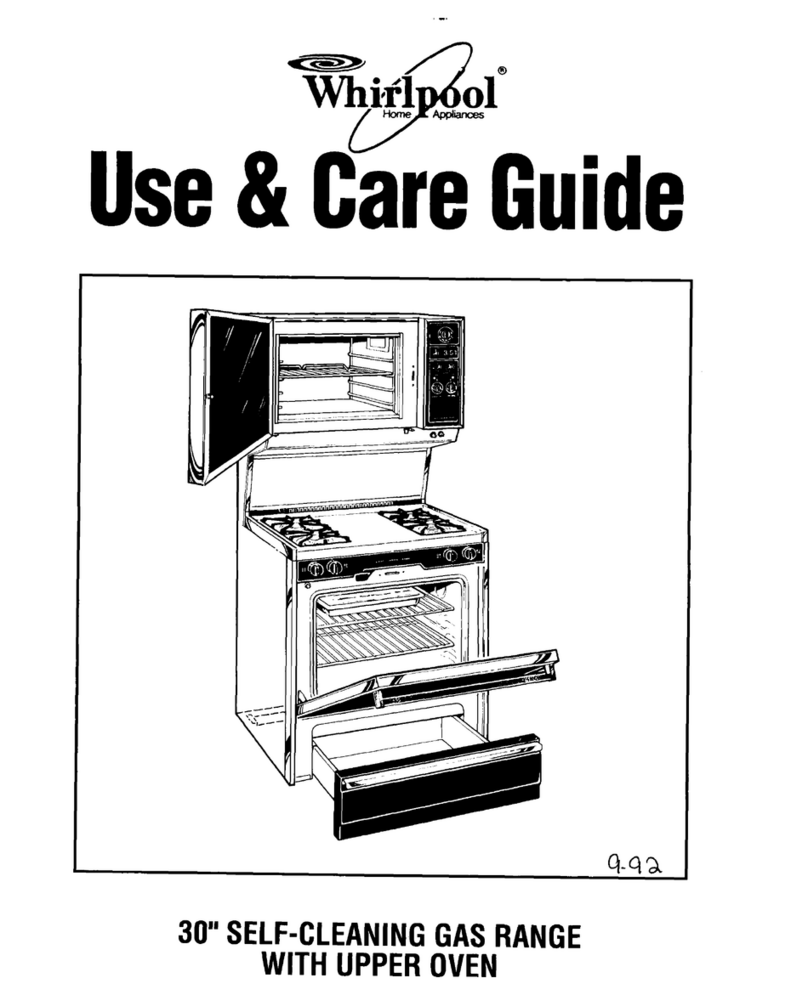

Now Start.. .

With range in kitchen.

1

Remove racks and other parts

n

from inside oven

2

Place one fool on the shipping

n

base. Tilt

range

forward slightly

to free rear legs. Genlly lower range to

floor Tilt range backwardsunill front legs

are free

3

Remove shipping materials,

n

tape and protective film from

range Do rot remove cardboard

shipplng base at this lime

4

Adjust the leveling legs lo a

n

pant where Ihe range base

does not touch the floor

5

Plug the electrlcal cord into the

. grounded oullel.

Keep shipping base under range.

Failure to do so could cause

damage to floor covering.

6

Move the range 1n10 flnal

n

aoerallng positron Remove

corddsnrd shipping piece from under

rO”Q*

7

n

Place rock in oven. Place level

on rack. first side to side then

front to back. If the range Is not level.

screw Me legs up or down to adjust.

Note: Oven must be level fofsofisfactory

baking conditions.

_ -

8

Assemble the flerlole

n

connector from the gas

supply pipe to ihe pressure regulator ir,

order: manual shti-aft valve. Yz” nipple

Yz” adapter. flexible connector. %”

adapter. and Y? nlpple.

All connecllons ml;st be wren&-

Ilghtened.

Flexible connector

K;nlpple / K” nlpple

\ A

Manual

K” adapter K” adapter

shut-off

MIW

and possible fire or explosion.

9

Use pipe-joint compounds

n

resistant to the action of L.P gas

to seal all gas connections. Check

thd he mnge shut-off valve is open. If

flexible’conrecton are used. be cerlain

connectors are no1 kinked

10

Open the shukff valve In

n

the gas supply line. Wait a

few minutes far gas to move through

lhe gas line.

Fire Hazard

Do Not use on open flame to tesl

for leaks from gas connections.

Checking for leaks wilh 0 flame

may result in a fire or explosion.

11

Use a brush and liquid

n

detergenl to lest all gas

connections for leaks Bubbles arcunrj

connections WIII Indicde o leak If a

leak appears. shutoffaas valve ccnhols

and adjust connections Then check

connecllons oga~n NEYLR TEST FOR GAS

LEAKS WITH A MATCH OR OTHER FLAME.

Clean all detergent w!ufim from range