2 Manual Version 1.0.7

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Copyright © 2022 White Knight Fluid Handling | A Graco company 6 October 2022

Table of Contents

1Introduction..........................................................................................................................................................1

2Specifications & Performance.............................................................................................................................2

2.1 Pump Specifications ...................................................................................................................................2

2.2 Dimensions.................................................................................................................................................2

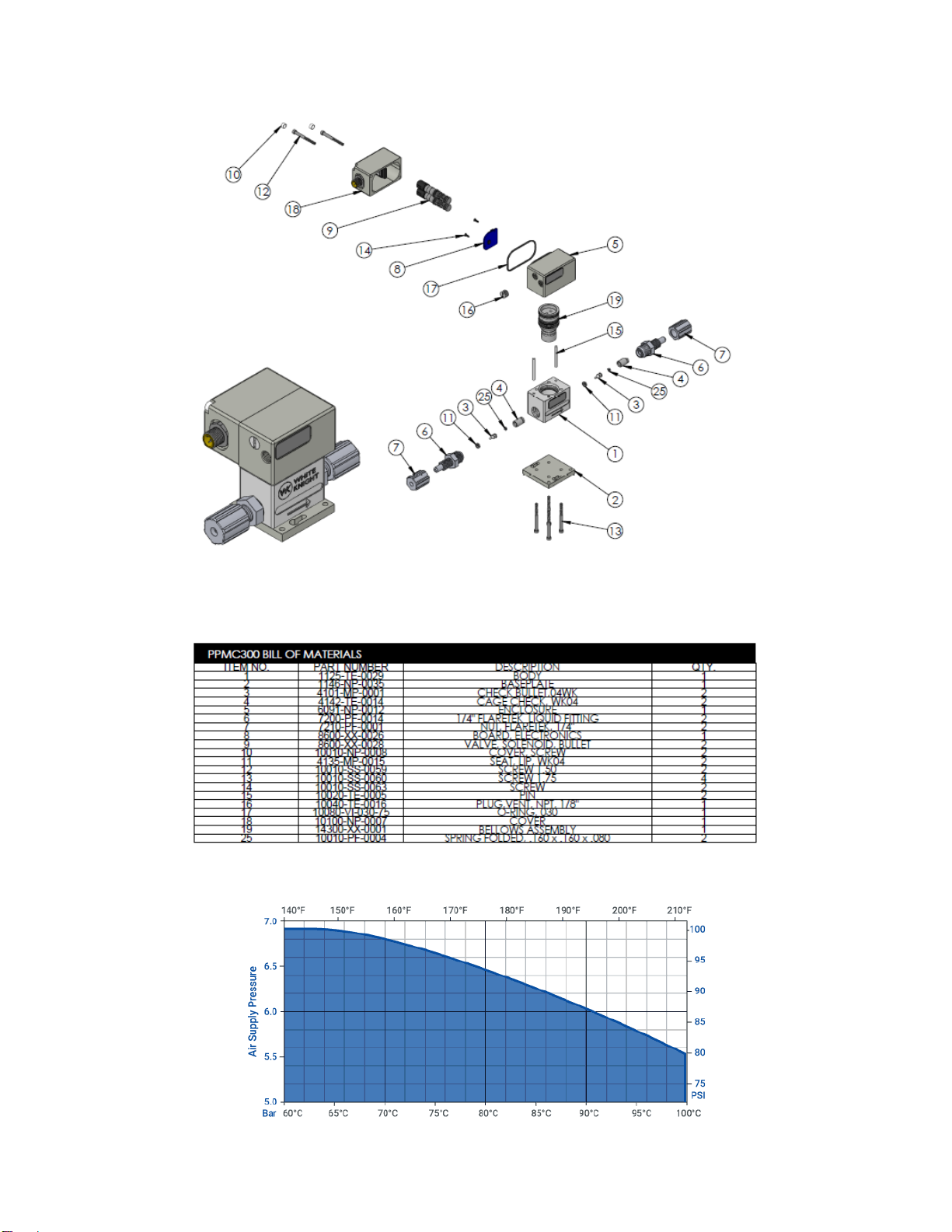

2.3 Exploded View............................................................................................................................................3

2.4 Temperature Limitations.............................................................................................................................3

3Pump Warranty....................................................................................................................................................4

4Installation and Precautions................................................................................................................................5

4.1 Precautions.................................................................................................................................................5

4.2 System and Pump Environment Recommendations/Requirements ..........................................................6

4.3 Installation Advantages...............................................................................................................................6

4.4 Installation Instructions...............................................................................................................................7

4.5 Connections................................................................................................................................................8

5Pump Control.......................................................................................................................................................9

5.1 Wire Connectors / Wire Leads....................................................................................................................9

5.2 Pump Operation..........................................................................................................................................9

5.2.1 Plug-n-Play .............................................................................................................................................9

5.2.2 External Control - Analog Input............................................................................................................ 10

5.2.3 External Control - Digital Input............................................................................................................. 11

5.3 Pump Orientation..................................................................................................................................... 11

5.4 Pump Dry Priming.................................................................................................................................... 11

5.5 Pumping for Accuracy.............................................................................................................................. 12

5.6 Flow Curves............................................................................................................................................. 12

6Pump Service & Rebuilds................................................................................................................................. 13

6.1 Ordering Instructions ............................................................................................................................... 13

6.2 Rebuild and Maintenance........................................................................................................................ 14

6.3 Rebuild Information.................................................................................................................................. 14

6.4 Return Pump to Factory........................................................................................................................... 14

6.5 Decontamination Instructions & Certificate of Decontamination ............................................................. 15