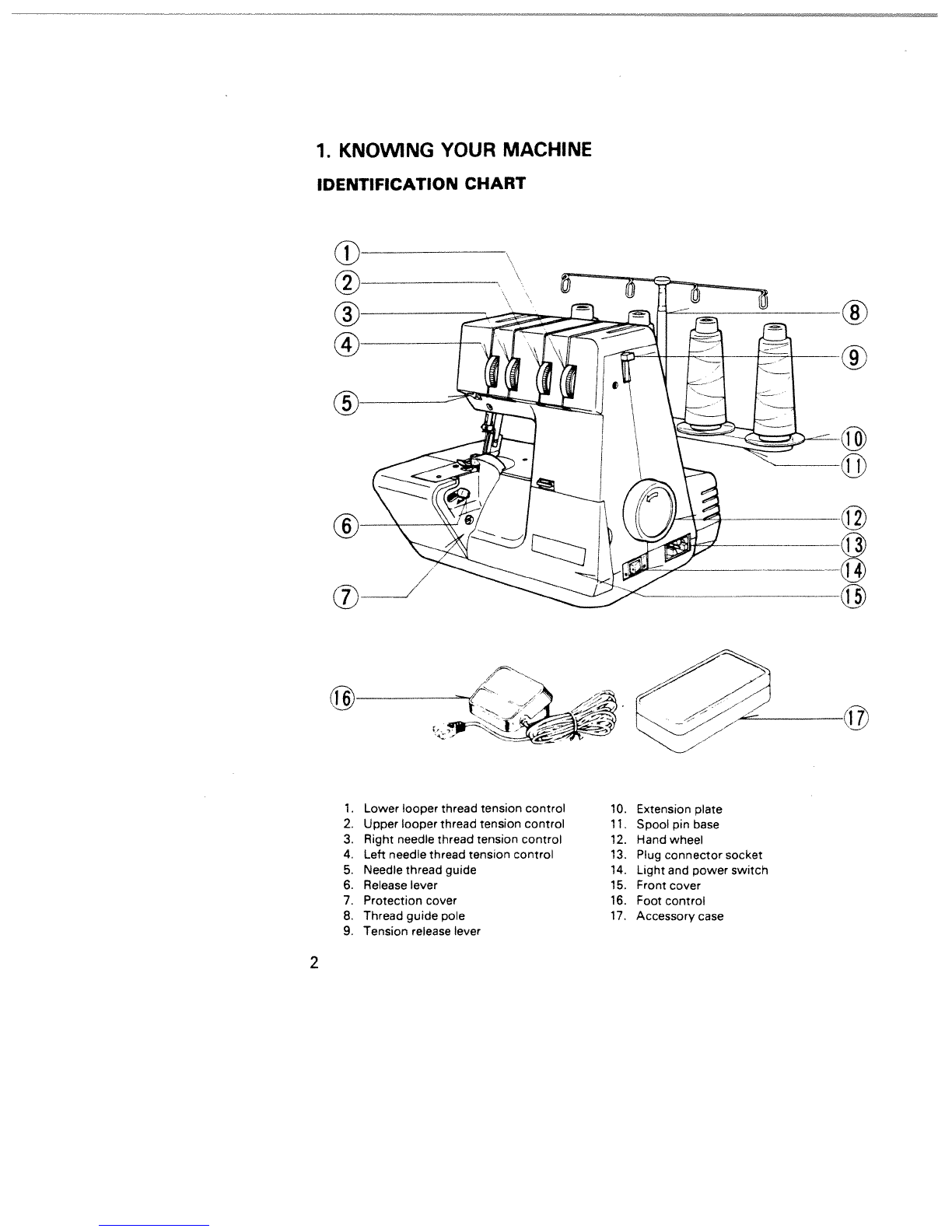

White SuperLock User manual

Other White Sewing Machine manuals

White

White 1010 User manual

White

White 510 Specifications

White

White 447 User manual

White

White 7234 User manual

White

White 1620 User manual

White

White 671 User manual

White

White 762 Owner's manual

White

White 503 User manual

White

White Crafter's Friend W300 User manual

White

White 1563 Installation instructions

White

White W2900 SUPERLOCK User manual

White

White 535 Operating instructions

White

White W2500 User manual

White

White 4040 User manual

White

White 1240 User manual

White

White De Luxe ZIG-ZAG 625 Installation instructions

White

White 656 User manual

White

White 915 User manual

White

White 1425 User manual

White

White SM2000 User manual