5

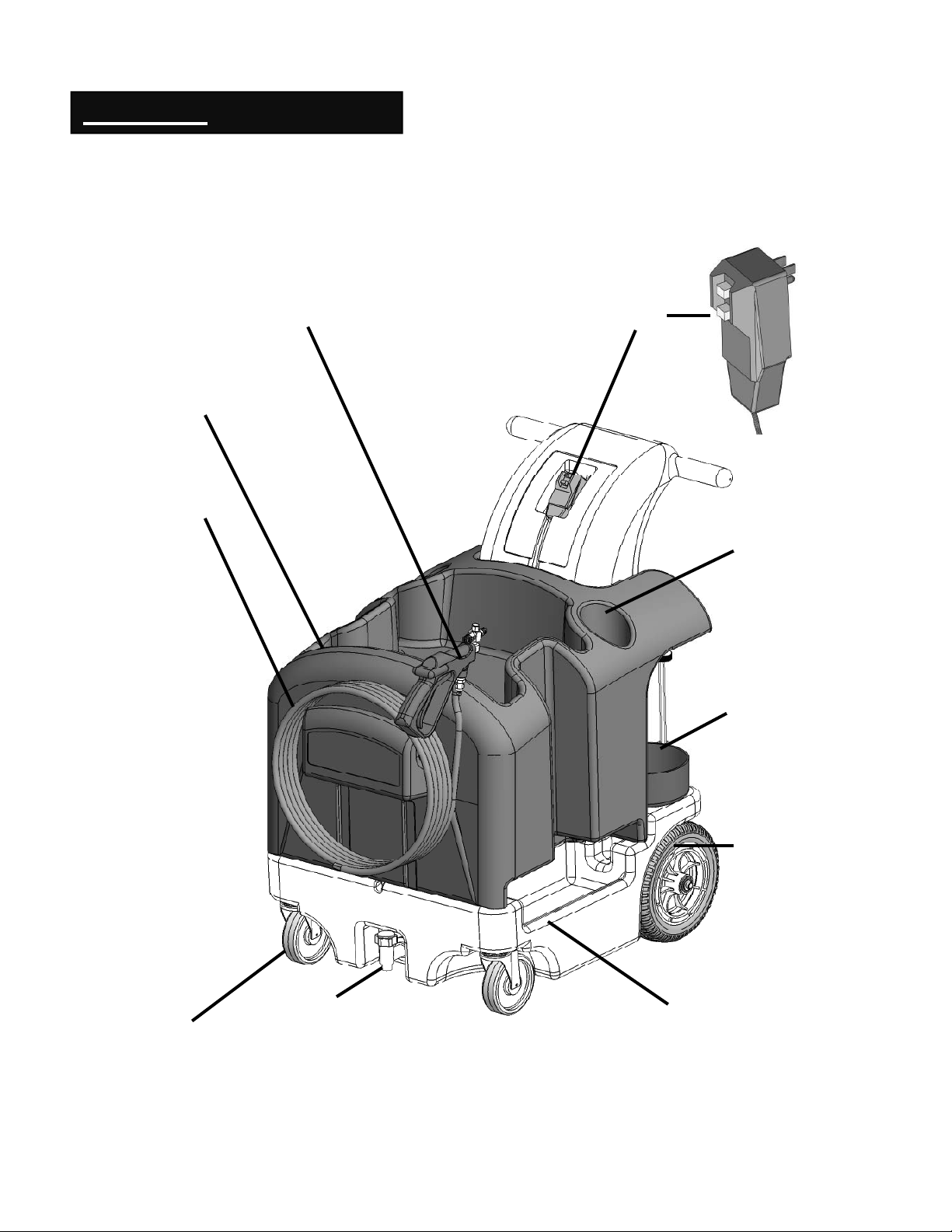

Initial Setup

The spray attachment is in the accessory box.

Attach it to the discharge hose.

Remove the black cap from the water fill port

(it rotates COUNTER CLOCKWISE to open).

Fill the tank with cool, clear tap water. See

Fig. D.

To connect the chemicals, remove the ship-

ping cap and the seal on your chemical bottle

and discard. Place the strainer and weight

into chemical bottle and screw the chemical

feed line cap on to bottle. See Fig.E.

1.

2.

3.

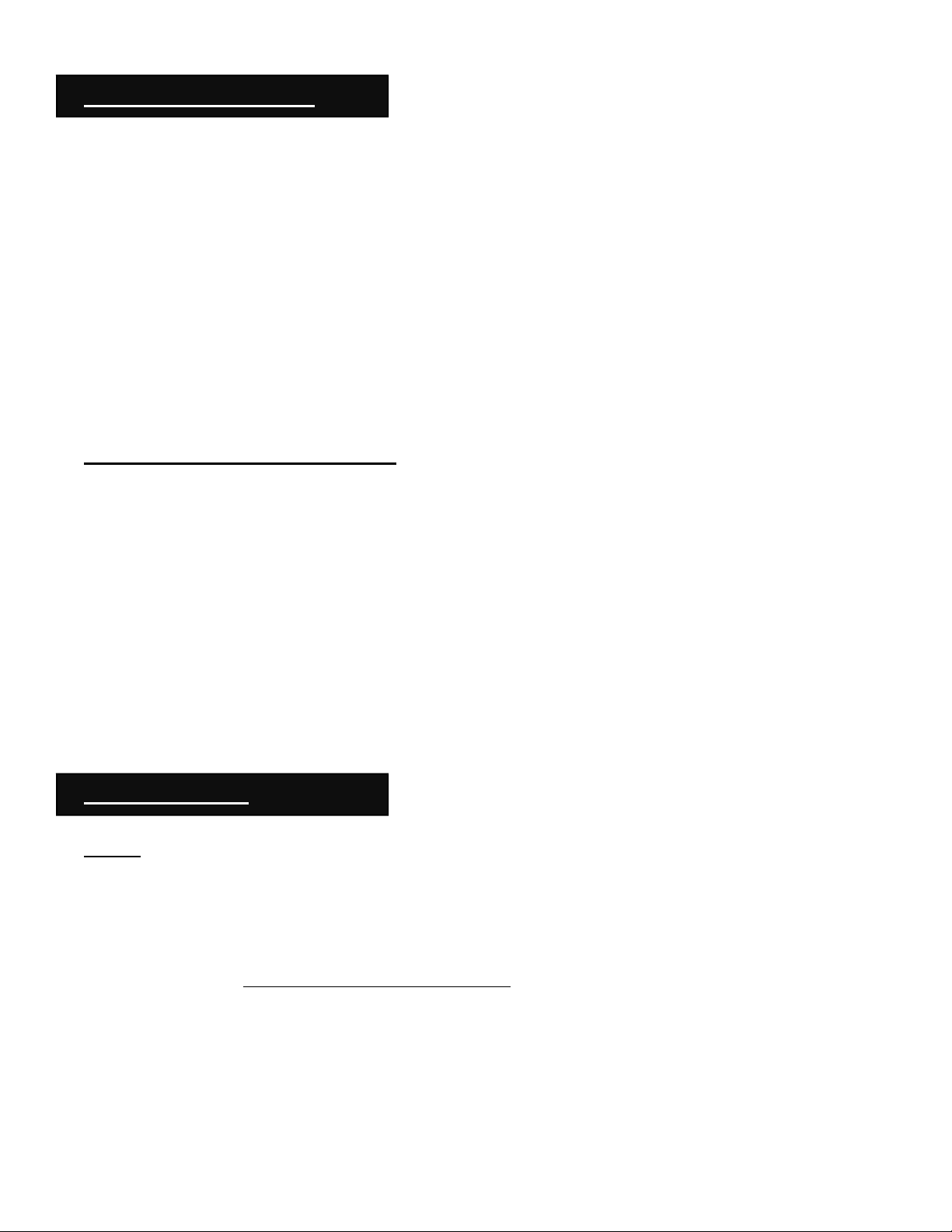

Prime the Unit

Set the nozzle on the spray attachment to “S”.

See Fig. F.

Set the chemical select valve to either of the

products (lower two positions on select valve).

See Fig. G.

Plug unit into 120 VAC Outlet.

Press and release the reset button.

Verify the red band at the base of the reset

button is not visible.

Press the test button.

Verify that the red band on the rest button ap-

pears.

Press and release the reset button.

Turn the power switch on. The pump should run

for a short time, then stop. (The pump will run

until the discharge pressure reaches the factory set

point. The pump will then turn off until the trig-

ger on the spray attachment is activated.)

Direct the spray nozzle into a drain or other con-

tainer and pull the trigger.

Run until a steady spray pattern is established,

1.

2.

3. a.

b.

c.

d.

e.

4.

5.

6.

Water fill port

Fig. D

weight

strainer

Fig. E

chemical feedline

cap

S

Rollover Valve

Spray attachment

R

Fig. F

Illuminated Power Switch

Fig. G

Fuse Holder Rinse

Settings

Chemical “A” Chemical “B”

Chemical “B”

Chemical “A”

without air in the water stream.

Release the trigger. The pump should stop almost

immediately. If it does not, operate the unit longer

as it is not fully primed.

7.

Turn the selector to the other product and repeat.8.

1.