WIELANDER+SCHILL InvertaPuls IP4-3 User manual

InvertaPuls IP4-3

02/2021

MIG-MAG Welding Inverter

Operation Manual REV 2.1

InvertaPuls IP4-3 Operation Manual

Page 2

CONTENT

1INTRODUCTION ............................................................................................................ 4

1.1 PRODUCT INTRODUCTION ........................................................................................... 4

2SETUP............................................................................................................................ 4

2.1 SETUP CONDITIONS .................................................................................................... 4

2.2 SELECTING THE ACCESSORIES .................................................................................... 4

2.3 CONNECTING TO THE ELECTRIC NETWORK .................................................................... 5

2.4 CONNECTING THE MIG/MAG TORCH ........................................................................... 5

2.5 TORCH WIRE LINER..................................................................................................... 6

2.6 THE FEEDING UNIT ...................................................................................................... 7

2.7 CONNECTING THE PRESSURE BOTTLE .......................................................................... 7

2.8 CONNECTING THE GROUND CABLE ............................................................................... 8

2.9 MMA –TIG WELDING CONNECTION ............................................................................ 8

3SAFETY AND FIREINSTRUCTION ............................................................................... 9

WELDING IN THE ENVIRONMENT WITH HIGHER ELECTRICAL DANGER......................................... 10

4OPERATION ................................................................................................................ 11

4.1 SWITCHING ON THE MACHINE ................................................................................... 11

4.1.1 Power-on sequence........................................................................................ 11

4.2 OPERATING PANEL................................................................................................... 11

4.2.1 Welding mode selection ................................................................................. 12

4.2.2 Welding process selection.............................................................................. 14

4.2.3 Selection of the additional material................................................................. 15

4.2.4 Selection of the additional material diameter.................................................. 16

4.2.5 MENU............................................................................................................. 16

4.2.5.1 Global menu parameters ............................................................................. 17

4.3 SET UP,ADJUSTMENT AND DISPLAY DESCRIPTION........................................................ 18

4.3.1 Welding power set up ..................................................................................... 18

4.3.2 Arc length correction synergic mode .............................................................. 18

4.4 JOB MODE.............................................................................................................. 19

4.4.1 Editing / saving the JOB ................................................................................. 19

Operation Manual InvertaPuls IP4-3

Page 3

4.5 SELECTING THE ACTIVE FEEDER ................................................................................ 19

4.6 PARAMETERS SETUP FOR DIFFERENT FEED UNITS ....................................................... 19

4.7 ARC CONTROL........................................................................................................ 20

4.8 FACTORY SETUP ...................................................................................................... 20

5MAINTENANCE ........................................................................................................... 21

5.1 DISPOSAL OF THE MACHINE....................................................................................... 21

6TECHNICAL DATA ...................................................................................................... 22

7AVERAGE CONSUMPTION VALUES FOR WELDING .............................................. 24

7.1 AVERAGE WELDING WIRE CONSUMPTION FOR MIG /MAG WELDING ............................. 24

7.1.1 Steel welding wire .......................................................................................... 24

7.1.2 CrNi welding wire............................................................................................ 25

7.1.3 Aluminium welding wire .................................................................................. 25

7.1.4 CuSi welding wire ........................................................................................... 25

7.2 AVERAGE SHIELDING GAS CONSUMPTION FOR MIG /MAG WELDING............................. 26

7.2.1 MIG / MAG steel welding................................................................................ 26

7.2.2 MIG / MAG aluminium welding ....................................................................... 26

7.3 AVERAGE SHIELDING GAS CONSUMPTION FOR WIG WELDING ....................................... 26

8TROUBLESHOOTING ................................................................................................. 26

9DISTRIBUTORS WORLDWIDE ................................................................................... 29

10 EU-DECLARATION OF CONFORMITY ...................................................................... 30

InvertaPuls IP4-3 Operation Manual

Page 4

1 INTRODUCTION

1.1 Product Introduction

InvertaPuls IP4-3 welding machine is compact pulse MIG-MAG welding inverter especially

developed for car body repair. The unique benefit is triple wire feed unit which together with

its excellent welding properties for thin sheet metal as well as aluminum and CuSi makes it

possible to use this device to repair all kinds of vehicles with fine quality results.

Be aware of danger resulted from welding and follow the safety and fire instructions.

It`s necessary to keep the device on a dry place, to protect device against moisture. It`s not

advisable to use the device on the open air during rain.

2 SETUP

2.1 Setup conditions

It´s necessary to set the device for welding in protection atmosphere on a dry place with the

sufficient area for cooling. The device is designed for use in covered area (under roof).

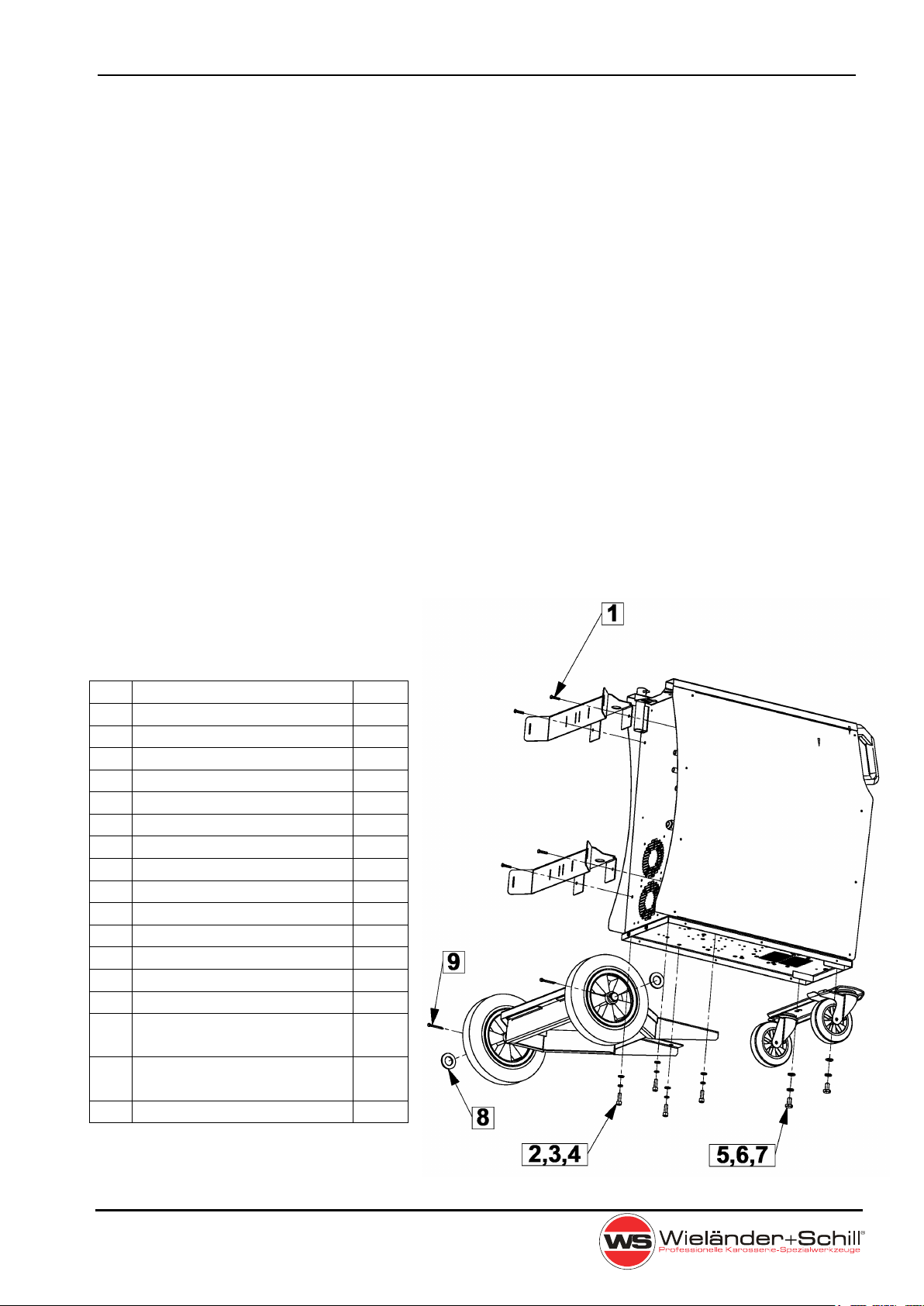

2.2 Selecting the accessories

Please check the machine for possible

transport damages before use!

1.

screw M5x16

4St

2.

screw M8x16

4 St

3.

spring washer M8

4 St

4.

U-disc M8

4 St

5.

screw M10x40

2 St

6.

spring washer M10

2 St

7.

U-disc M10

2 St

8.

U-disc M24

2 St

9.

split pin 3.5x40

2 St

10.

2x20l place for gasbottle

1 St

11.

front wheel set

1 St

12.

rear wheels

2 St

13.

rear axle

1 St

14.

gas connecting hose

3 St

15.

belt for gas bottle

4 St

16.

MIG torch,

Steel Version

1 St

17.

MIG torch,

CuSi/Alu Version

1 St

18.

ground cable

1 St

Operation Manual InvertaPuls IP4-3

Page 5

2.3 Connecting to the electric network

Check if the voltage stated on the device label complies with rated

voltage of alternate voltage of your electric network.

The device can be connected to electric socket equipped with protective contact installed

by authorized electrician. The electrical circuit of the socket must be protected by a fuse or

a circuit breaker.

Refer to the Technical Data on pages 22-23 for the required amperage.

The device is delivered without plug. For connections can be used only plugs and sockets

according to CEE standard.

2.4 Connecting the MIG/MAG torch

- For torch connecting is used EURO Standard torch

connector.

- Please, tighten the connector well to avoid the contact

resistance.

- Never use damaged torch.

Connect the welding conduction main connecting plug into the main socket on the front

side. Secure it with the lock nut.

Work piece

clamp

Torch A

Torch B

Torch B

state LED

Torch A

State LED

Torch C

Torch C

state LED

InvertaPuls IP4-3 Operation Manual

Page 6

2.5 Torch wire liner

For mild steel, the wire feed tube consists of a steel spiral. When using wire electrodes

made of chromium-nickel-steel and of aluminum and other metals, a tube of wear-resistant

plastic (for example Teflon) is used. Plastic guides have a lower friction coefficient than

steel.

Make sure the contact tip match the manufacturer’s recommendations for type and diameter

of used wire.

In case Teflon liner is used is it necessary to use contact neck liner out of brass to provide

good current conduction to the fill wire.

Material Wire diameter Liner material Liner color

Fe 0,8mm steel spiral

or

Teflon

1,0mm

1,2mm

Inox 0,8mm Teflon

1,0mm

1,2mm

AlMg, AlSi 1,0mm Teflon

1,2mm

CuSi3 0,8mm Teflon

1,0mm

1,2mm

CuAl8

0,8mm Teflon

1,0mm

Liner color:

Blue: Art.N° 337139 Red: Art.N° 337142 Black: Art.N° 337147

Operation Manual InvertaPuls IP4-3

Page 7

2.6 The feeding unit

Please choose the feeding rolls correspond to used welding wire.

Material

Shape

Diameter

Article-Number

Fe

Inox

CuSi

CuAl

0,6/0,8mm

0.8/1.0mm

1,0/1,2mm

337219

337220

xxx

AlMg

AlSi

0,8/1,0mm

1.0/1.2mm

xxx

337221

When the feeding wheel is set up, you can see on the front side of the wheel the assigned

welding wire diameter (value is in mm).

2.7 Connecting the pressure bottle

While adjusting the gas flow rate, the unit must be switched on and the burner switch must

be pressed to open the solenoid valve. To avoid unnecessary wire consumption, open the

leaf spring of the wire feeder.

Determination of the gas flow rate:

Steel - 10x wire Ø

Aluminium - 12x wire Ø

Example: Wire Ø 0,8mm x 10 = 8Liter/minute

Pressure

adjustment

Feeding

rolls

Fixing

point

InvertaPuls IP4-3 Operation Manual

Page 8

2.8 Connecting the ground cable

It`s necessary to connect the grounding clamp in the very vicinity of welded place. The

transfer contact must be metallic clear free of dust and color.

2.9 MMA – TIG welding connection

TIG Connection MMA Connection

Work

piece

TIG Torch

Stick Holder

Operation Manual InvertaPuls IP4-3

Page 9

3 SAFETY AND FIREINSTRUCTION

Keep this device away from children. You must follow the safety and fire instructions when

you work with the welding device and for welding in a protective atmosphere. Follow all

regulations for the prevention of accidents during "welding, cutting and similar working

activities".

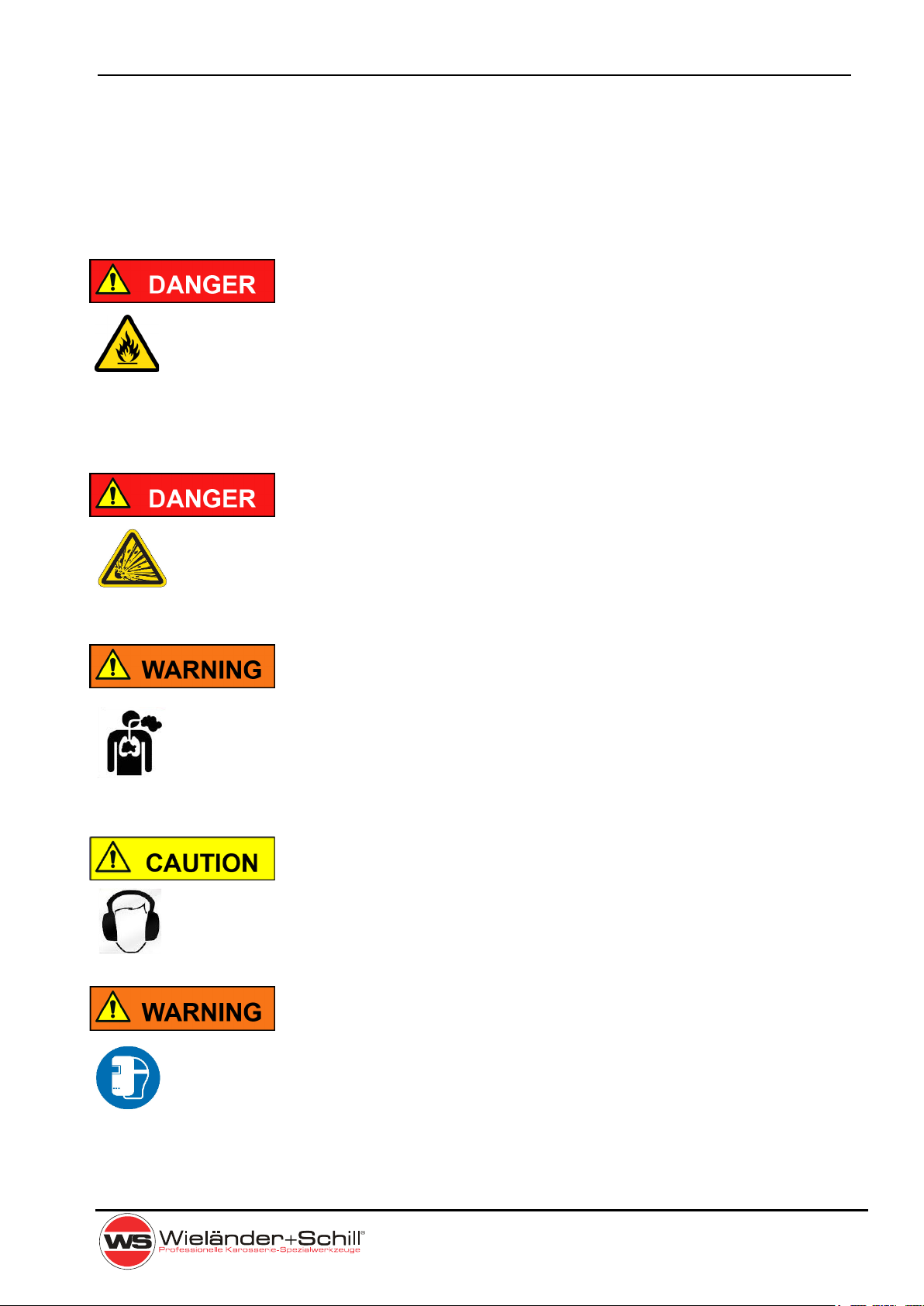

WARNING FIRE HAZARD!

Be sure the area is safe before doing any welding.

Remove all flammable material within 10m of the welding area.

Quench hot metal or allow it to cool before handling or before letting

it touch combustible materials.

Never weld containers with potentially flammable materials inside –

they must be emptied and properly cleaned first.

Ventilate potentially flammable atmospheres before welding

WARNING EXPLOSION RISK!

It’s possible that harmless substances in closed containers may

generate excessive pressure when heated.

Move containers with flammable or explosive liquids away from the

working area!

Never heat explosive liquids, dusts or gases by welding!

CAUTION TOXIC FUMES!

Smoke and gases can lead to breathing difficulties and poisoning

Use local exhaust ventilation to remove fumes from the air.

Remove all coatings and solvents from the metal before welding.

Wear suitable breathing apparatus if appropriate!

Never weld containers with potentially toxic materials inside. Empty

and properly clean the container first.

CAUTION Noise exposure!

Prolonged exposure to noise from welding, cutting or similar work

can damage hearing.

Use approved ear protection.

Warn others nearby about the noise hazard.

WARNING ARC RAYS CAN BURN EYES AND SKIN!

The welding arc produces intense visible and invisible rays that can

burn eyes and skin.

Wear eye protection (welding helmet) with appropriate lens shading

to protect your eyes from the arc’s ultraviolet and infrared rays.

Wear protective clothing to protect against burns caused by

ultraviolet light, sparks and hot metal.

Flame-retardant clothing to cover all exposed areas.

Use protective screens or barriers to protect others from flash and

glare.

InvertaPuls IP4-3 Operation Manual

Page 10

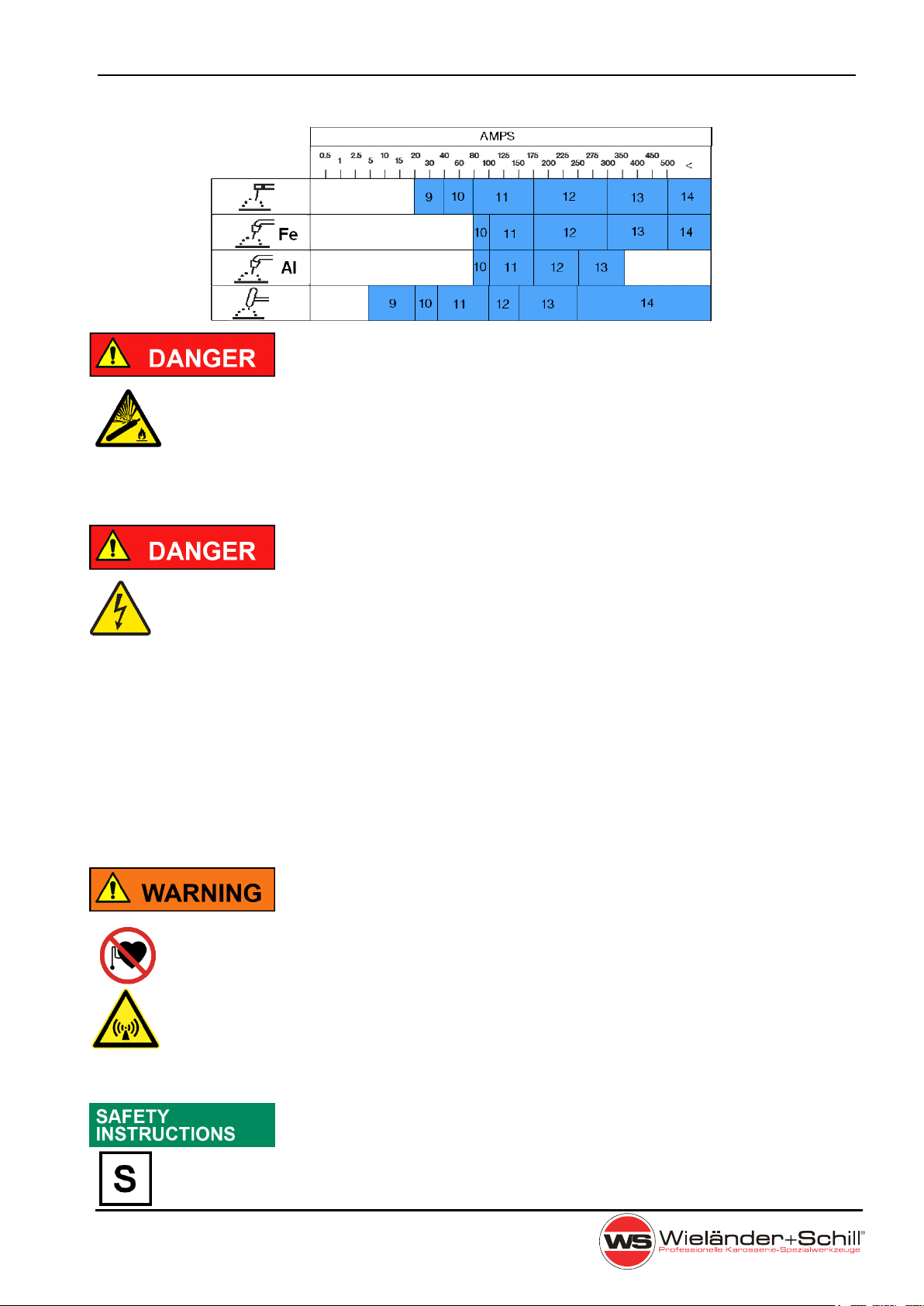

Recommended welding helmet lens shade according ISO 4850:

CYLINDERS CAN EXPLODE

Gas cylinders contain gas under high pressure which can explode

if damaged or exposed to a heat.

Regional safety regulations for pressurised gas must be followed.

Due to high pressure inside the bottles (up to 200 bar) it is

necessary to secure them against mechanical damage,

overturning, downfall, h

eating up (max 50°C), against sunshine

exposure for a longer time and against strong frost.

WARNING RISK OF ELECTRIC SHOCK

Voltages can cause potentially fatal electric shocks and burns on

contact. Even low voltages can cause a shock and lead to

accidents.

Install and ground this equipment according to the instruction

manual and in accordance with national and local standards.

Wear the full personal protective equipment (depending on the

application)!

Never touch live components such as welding current sockets or

stick, tungsten or wire electrodes!

Always place torches and electrode holders on an insulated

surface!

The device must be placed out of higher electrical danger

environment. You can be in the endangered environment with a

torch only.

CAUTION ELECTROMAGNETIC FIELDS

Device is constructed according IEC 60974-10 class A and is

intended to work only in industrial areas.

When operating welding machines, electro-magnetic interference

can occur.

The user is responsible for any interference caused by welding.

Pacemaker and hearing aid operation can be affected by magnetic

fields from high currents. Pacemaker and hearing aid wearers

should consult a doctor before going near any arc welding

machines.

Welding in the environment with higher electrical danger

The welding device is constructed in compliance with IEC 60974

as a device suitable for welding in the environment with higher

electrical danger.

Operation Manual InvertaPuls IP4-3

Page 11

4 OPERATION

4.1 Switching ON the machine

Always use the main switch on the back side of the machine to turn On and Off the device,

never use the power plug for this purpose!

4.1.1 Power-on sequence

After powered special power on sequence is started on the operating panel, to give the user

information about the firmware. First all segments are lighted up, than after following

information are displayed:

a)

Firmware type (in material Volt window)

EA – ACT panel

b)

Model (in Ampere window)

240

c)

Firmware revision (in Ampere window)

r11 major . minor revision numbers.

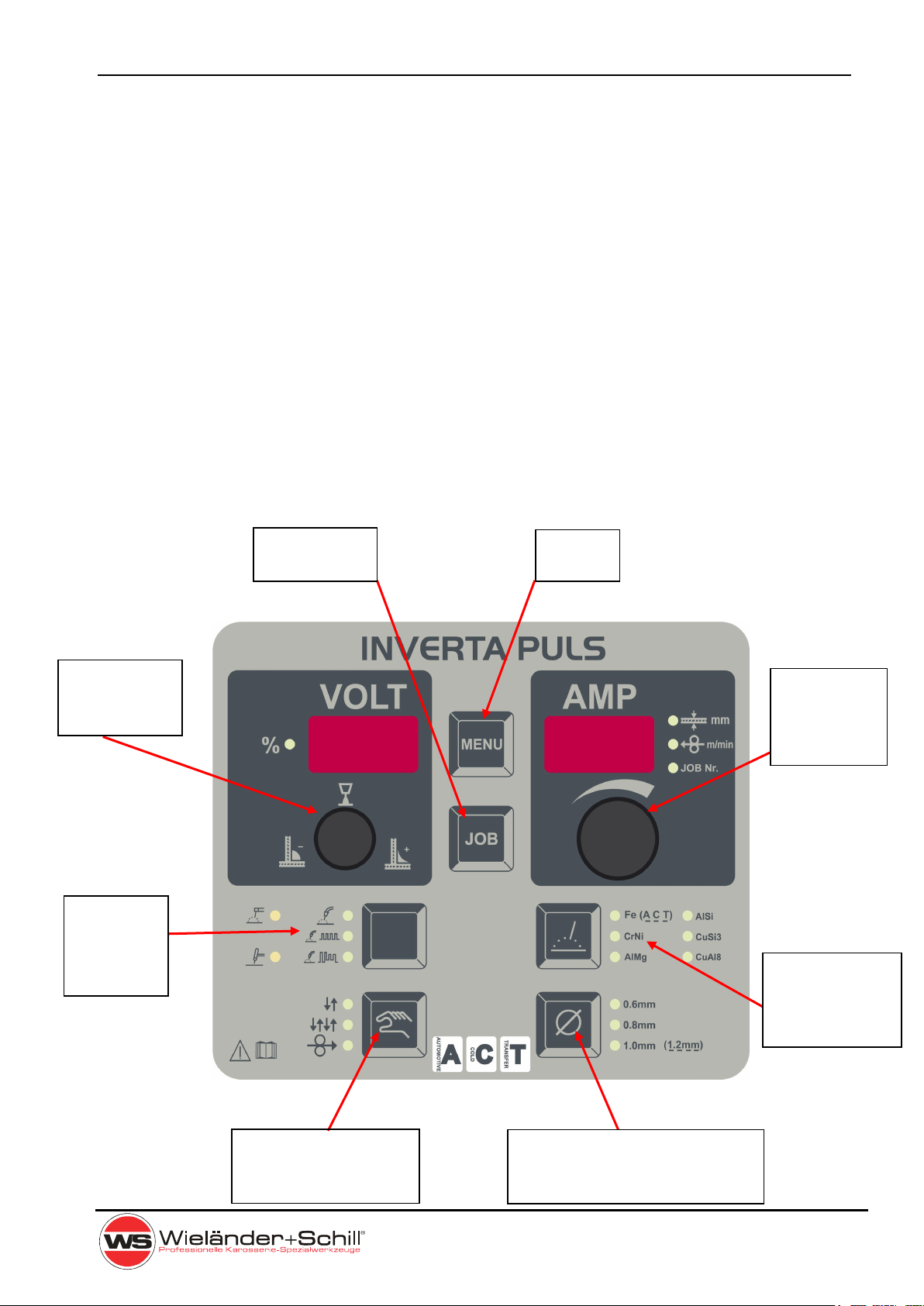

4.2 Operating Panel

4.4

JOB Mode

4.2.5

MENU

4.3.1

Welding

power

set up

4.3.2

Arc length

correction

4.2.2

Welding

process

selection

4.2.3

Filler wire

material

selection

4.2.1

Welding mode

selection

4.2.4

Filler wire diameter

selection

InvertaPuls IP4-3 Operation Manual

Page 12

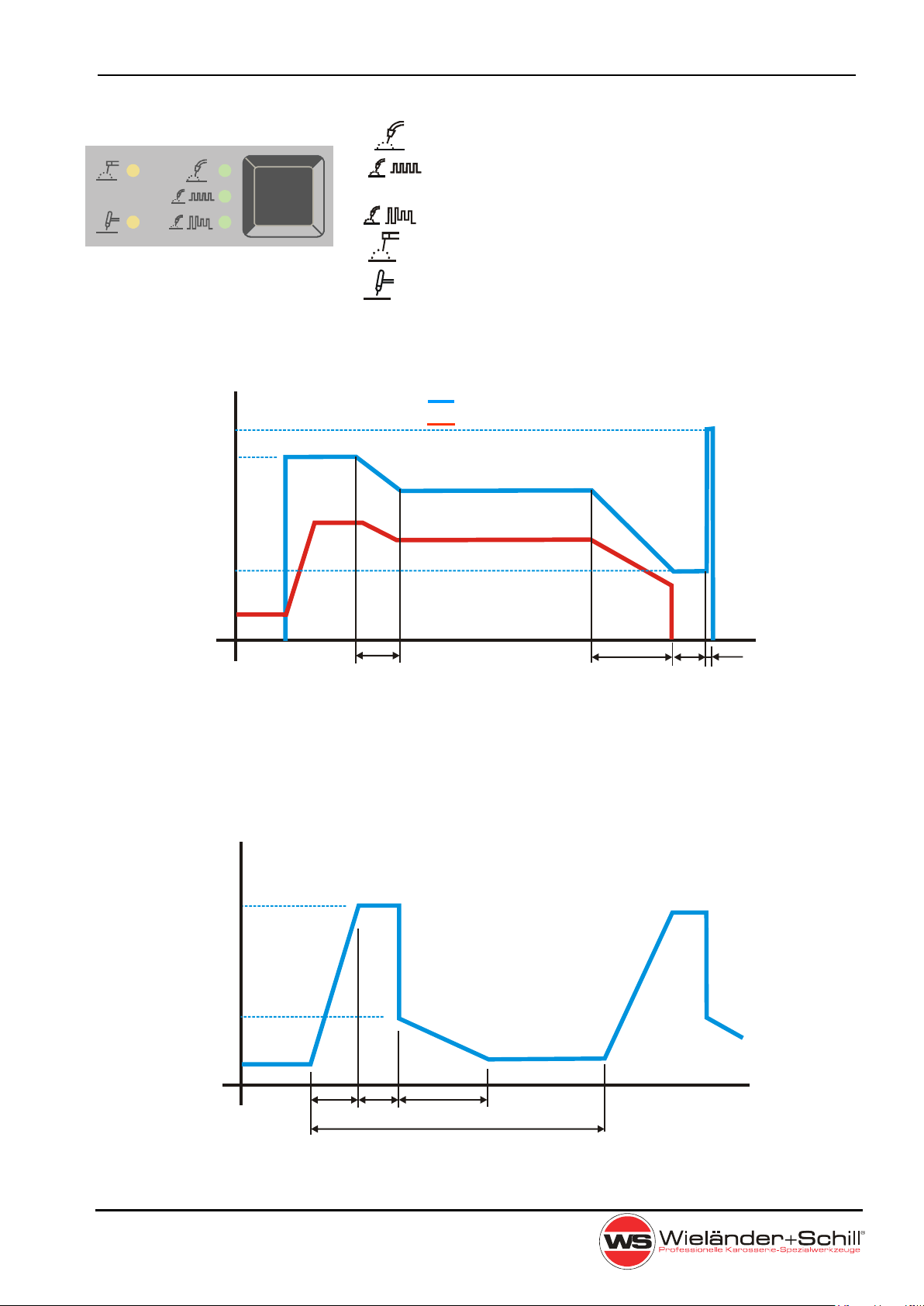

4.2.1 Welding mode selection

(Not available if MMA/TIG selected)

- 2- cycle mode

- 4- cycle mode

- Manual wire inch mode. In wire speed window is

possible to adjust the speed for manual feed. Feeding is

activated by pressing the trigger button.

2-TACT Mode / 4-TACT Mode

2-TACT/4-TACT relates to the function of starting button (trigger) on the welding torch.

Differences in operation of this two modes are shown in following pictures:

t

P

P

HOT

P

WELD

t

TRIGGER

2-TACT MIG/MAG operation

t

P

Hot start

level

Welding

Crater fill

level

t

TRIGGER

cFt

hSt

4-TACT MIG/MAG operation

Operation Manual InvertaPuls IP4-3

Page 13

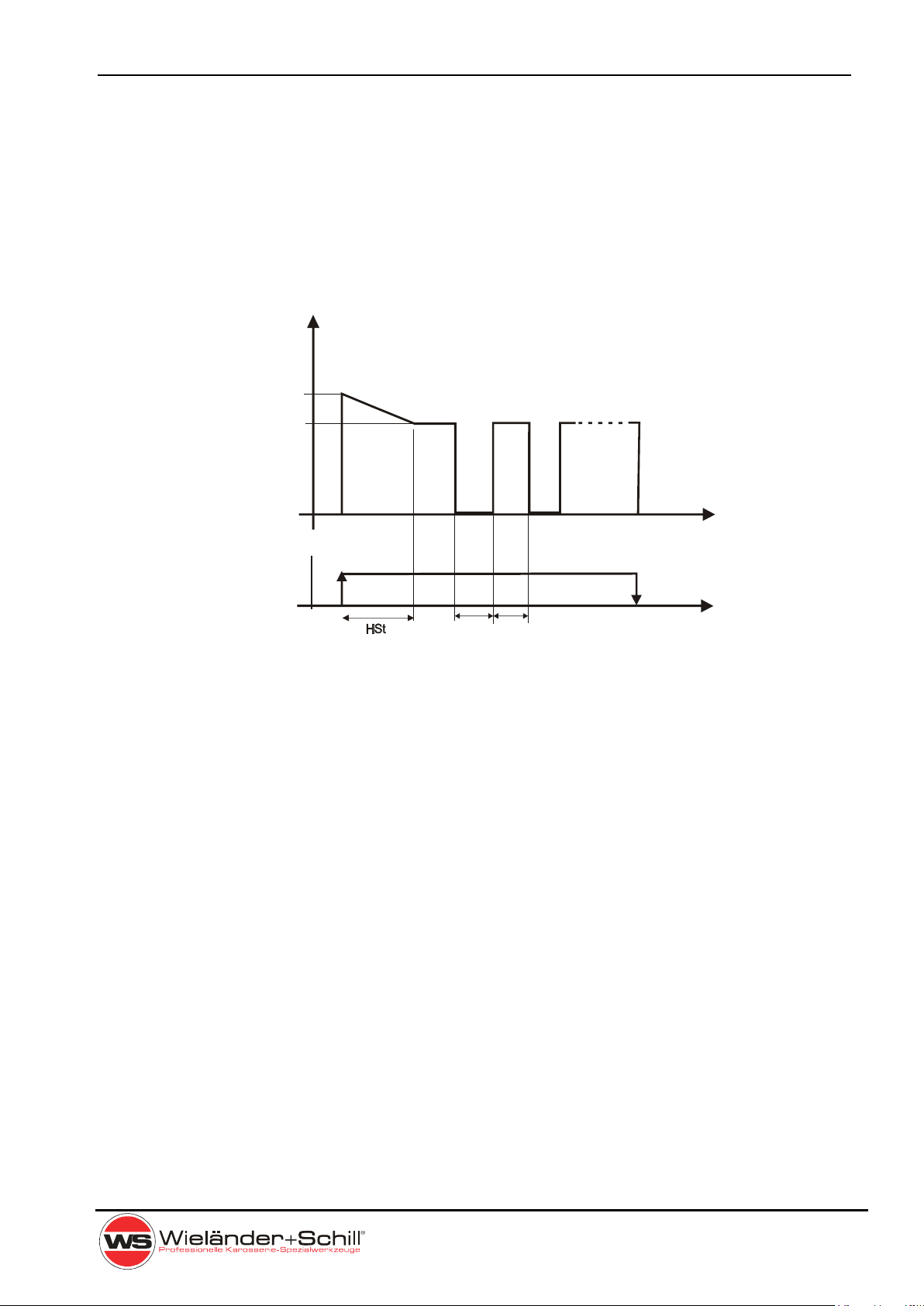

Interval welding

To activate interval welding program, the pause time must be set greater than 0 (factory

setting). To disable interval welding feature, set the pause time parameter to 0 (menu

parameter number 1.9 – PAU). Interval function is available in both – 2cycle and 4cycle

operation

t

P

PHOT

PWELD

t

TRIGGER

PAu Act

2-TACT MIG/MAG operation

InvertaPuls IP4-3 Operation Manual

Page 14

4.2.2 Welding process selection

- Standard MIG/MAG welding process

- Pulsed MIG/MAG welding process (EcoPulse

only)

- MIG/MAG Double Pulse welding process

- MMA welding process

- WIG welding with Lift Arc ignition

Synergy parameters for MIG/MAG welding

hSL

hSt

Welding voltage

Wire speed

cSS

cFL

cFt

EPL

EPt

bbt

Time diagram of MIG/MAG weld

Synergy parameters for standard Pulse

Up

PL

bcL

FcL

PF

EPL

Prr PFr

Time diagram of Pulsed weld (without Hot start & Crater fill level)

Operation Manual InvertaPuls IP4-3

Page 15

MIG / MAG Double Pulse

Double pulse frequency –define a speed of interleaving hot and cold phases in double

pulse welding

Double pulse amplitude – power ratio between hot and cold phases in double pulse

welding

I

HOT

I

set

Frequency

Amplitude

Double pulse time characteristic

frequency

Amplitude

Double pulse weld – AlSi5 / 1.0mm wire

4.2.3 Selection of the additional material

(Not available if MMA/TIG selected)

Fe (ACT) - alloyed + non-alloyed steel, inert gas: 82%Ar + 18%CO2

(LED shines)

Fe (ACT) - Steel thin sheets ACT welding, inert gas: 82%Ar + 18%CO2

(LED flashes)

CrNi - Stainless steel AWS308LSi, gas: 87.5%Ar + 2.5%CO2

AlMg - Aluminum + magnesium, shielding gas: 100%Ar

AlSi - Aluminum + silicium, shielding gas: 100%Ar

CuSi3 - Copper silicium, shielding gas: 100%Ar

CuAl8 - Copper aluminium, shielding gas: 100%Ar

InvertaPuls IP4-3 Operation Manual

Page 16

4.2.4 Selection of the additional material diameter

0,6mm

0,8mm

1,0mm (1,2mm)

4.2.5 MENU

For enhanced adjustment is available MENU function.

Press and hold for 3 seconds

Operation Manual InvertaPuls IP4-3

Page 17

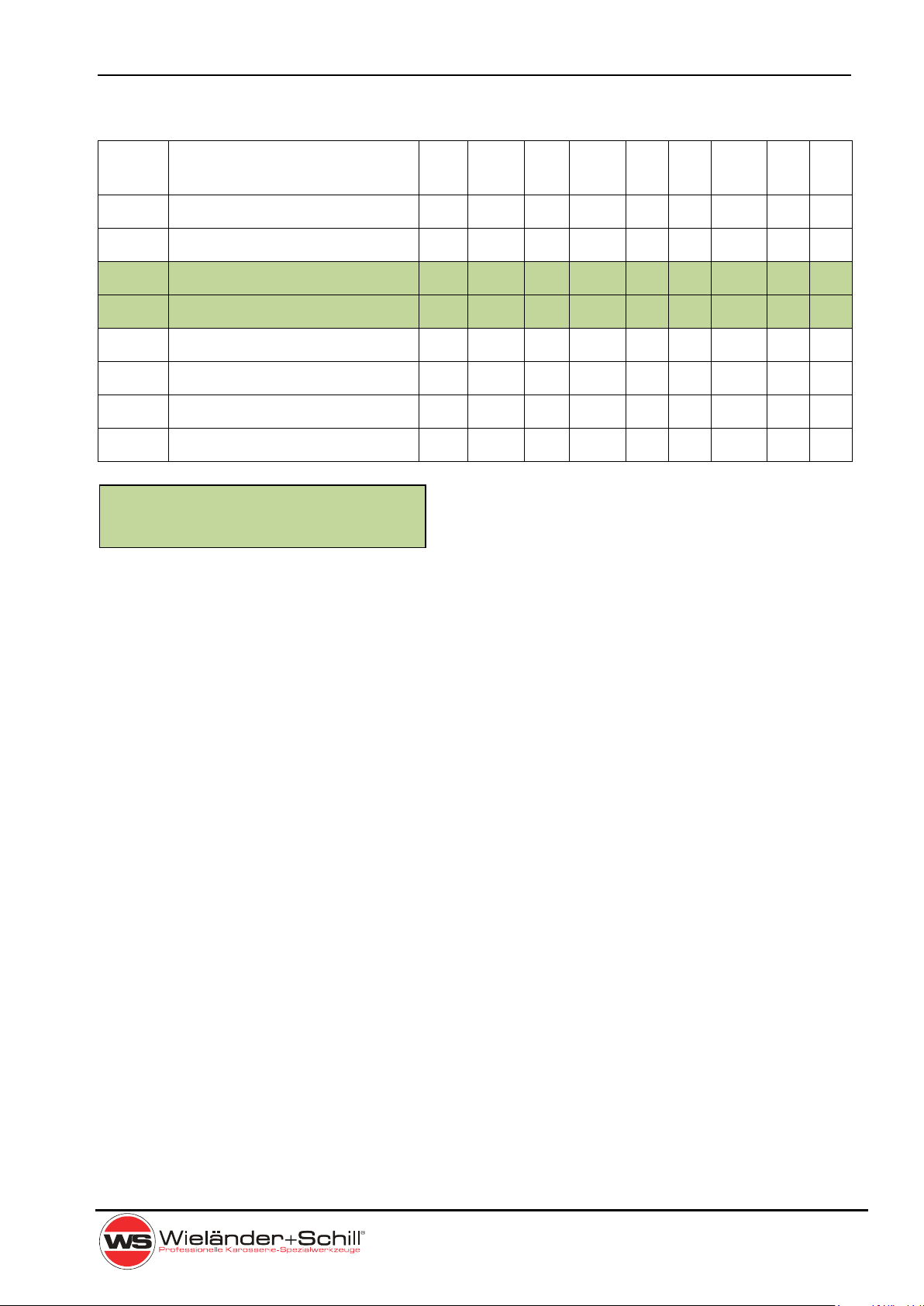

4.2.5.1 List of MENU parameters:

Display

Name

Description

Min.

Max.

Step

Unit

MIG

Pulse

MIG

Double

Pulse

MIG

MMA

TIG

GPr

Gas pre-flow time

0,0

10,0

0,1

sec

X X X - -

GPo

Gas post-flow time

0,0

10,0

0,1

sec

X X X - -

hSL

Hot-start level

100

199

1

%

X X X X -

cFL

Crater-fill level

1

100

1

%

X X X - -

hSt

Hot-start slope time

0,0

10,0

0,1

sec

X X X X -

cFt

Crater-fill slope time

0,0

10,0

0,1

sec

X X X - -

Act

Active time for interval weld.

0,0

10,0

0,1

sec

X X - - -

PAU

Pause time for interval weld.

0,0

10,0

0,1

sec

X X - - -

These parameters are reset to factory settings

when changing the material thickness selection.

Global menu parameters

Parameters that are independent of the selected filler material, wire diameter and base

material thickness are referred to as general parameters. All these parameters can be set by

the user in the menu. They remain saved and unchanged as long as the user does not

change the setting. The parameter group includes:

1. Gas pre-flow time

2. Gas post-flow time

3. Hot-start level – Hot start level in percent, based on the preselected

Welding current. Can only be> 100%.

4. Crater-fill level – Crater fill level in percent, relative to the selected one

Welding current. Can only be <100%

5. Hot-start slope time – a time which is needed to slope from hot start level to the

welding level. In sec.

6. Crater-fill slope time – a time which is needed to slope from welding level to the crater

fill level. In sec.

7. Active time – parameter for automatic interval welding, which defines an

active welding time in seconds

8. Pause time – parameter for automatic interval welding, which defines an

inactive time, when arc is off in seconds. If it is set to 0, interval

welding is disabled.

Synergetic controlled parameters

InvertaPuls IP4-3 Operation Manual

Page 18

4.3 Set up, adjustment and display description

4.3.1 Welding power set up

Teh welding-brazing machines are controlled with full

synergic feature (except Manual modus).

The welding power is to adjust just with one main rotary

encoder. By press of the encoder button, wire speed (in

meters/min) or material thickness (in millimeters) can be

selected.

In MMA and TIG mode is only Ampere setup possible.

4.3.2 Arc length correction synergic mode

In all MIG/MAG modes is possible to adjust length of

the welding arc. By turning the encoder in any direction

is display switching from Voltage mode to Arc length

correction mode (% LED active).

Arc length set to = 0 –

Arc length set to max. +

Arc length set to min. –

The settings made for the respective operating mode and

the additional material remain valid even after switching off

and on again!

Operation Manual InvertaPuls IP4-3

Page 19

JOB

JOB

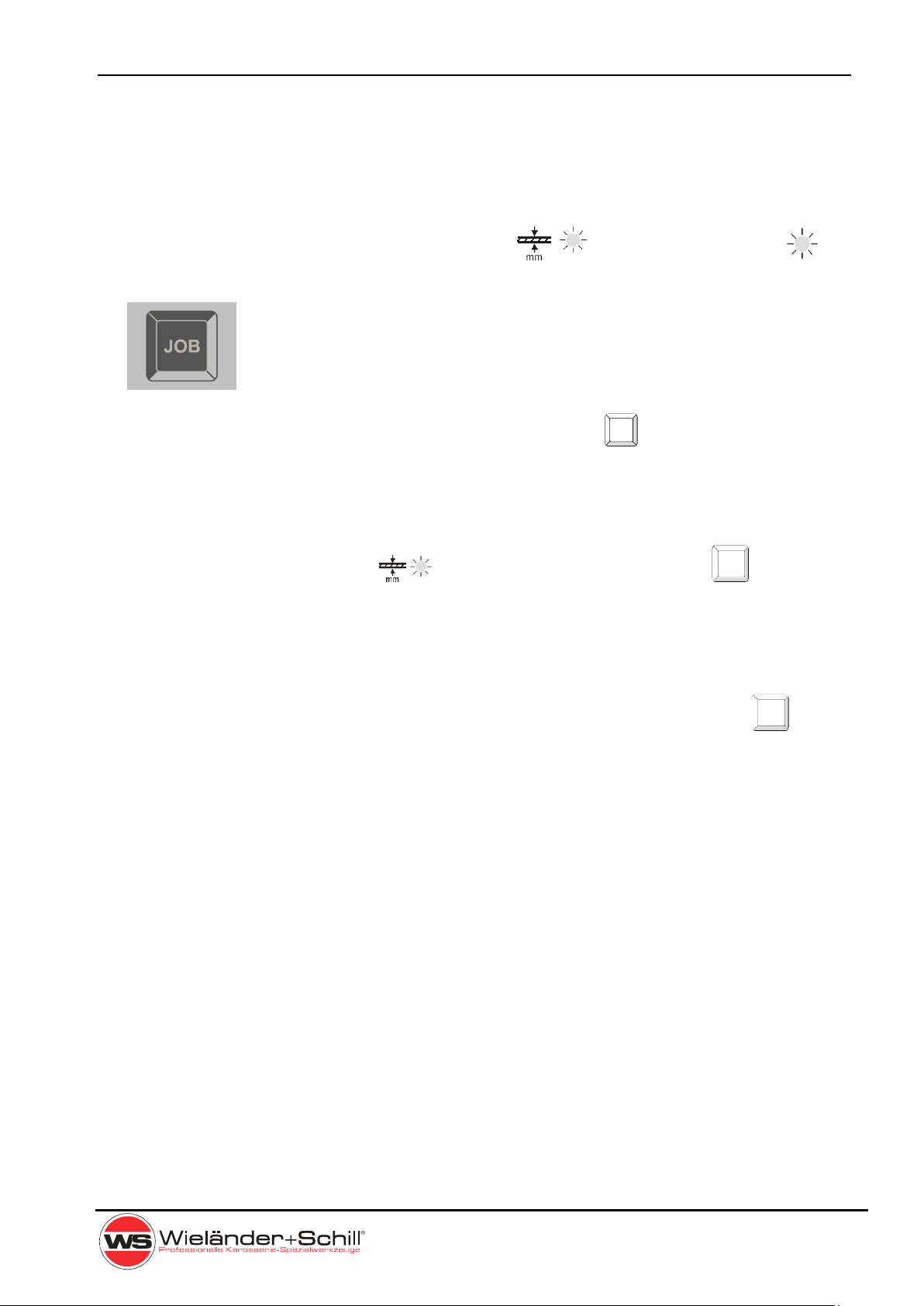

4.4 JOB Mode

The JOB mode allows you to store up to 100 individual parameter settings in addition to the

preset programs.

Change from synergic mode to JOB mode JOB is

made

by short press of the JOB button . After entered the Job

mode, number of actual job is shown in the Material thickness / JOB

window. There are 100 jobs available: J00 – J99. By Turning main

encoder can be chosen required job number.

While in JOB mode, there are no set up and adjustments available

except the JOB number and welding mode. If adjustment is required,

JOB editing must be activated – see following section

To quit from JOB mode press JOB button JOB again.

4.4.1 Editing / saving the JOB

While working in synergic mode , by long pressing the JOB button actual set

up

can be stored. After long pressing of JOB button, number of job starts to flash. This number

can be changed by encoder rotation, after desired job number is set by pressing the

encoder button actual set up is saved under this job number.

To edit actual job, set job number to change, by long pressing the JOB button the

material thickness start to flesh and any change of any parameter can be made. After

changes are made, by short press of encoder button will be stored.

4.5 Selecting the active feeder

Active feed unit selection is indicated by LED indicator above the corresponding euro torch

connector. To switch the idle feed unit on, must be just pressed the trigger button on the

corresponding torch. By pressing the trigger button on the not active feed unit, it will switch

to active state with automatic up-loading of all appropriate settings on the front panel. After

releasing the torch button and pressing it again the welding process will start.

4.6 Parameters setup for different feed units

There can be made specific setup for each feed unit. All settings made on the front panel

are belonging to the active feed unit and will be stored in internal memory in case of

switching the feed unit to idle state or switching the machine off. Always if some setup

should be done, the feed unit must be set as active.

InvertaPuls IP4-3 Operation Manual

Page 20

4.7 ARC Control

If there is no arc detected for more than 3 seconds during active welding the inverter will be

automatically switched off.

This feature may prevent user from some desired actions. In case of feeding the wire in the

torch, please use Manual feed mode described before.

4.8 Factory setup

With the following procedure the machine can be reset to factory setup.

This procedure will delete all stored job an will reset all parameters to the state at delivery!

Make sure that the machine is conected to the power

supply and switched off.

Hold this button depressed and switch the machine on

until the initial display test sequence is over and the code

menu is displayed.

Once in the code menu you will have to enter the

unique code U 01, A 01, B 01, C 01. Individual

numbers can be accessed by pressing voltage

encoder.

When you have entered all 4 numbers and you are sure

that they are correct then confirm the complete code by

depression of this button. The panel will be restarted in

order to apply new factory default settings.

Table of contents

Other WIELANDER+SCHILL Welding System manuals

Popular Welding System manuals by other brands

Ter Welding

Ter Welding Multi 250K instruction manual

STEINEL PROFESSIONAL

STEINEL PROFESSIONAL HG Roof Information

Lincoln Electric

Lincoln Electric RANGER 305 D CE Specification sheet

CARBONE

CARBONE Digi-Tig320ACDC Operator's manual

RODEX

RODEX RDX5128 instruction manual

Hypertherm

Hypertherm HT2000LHF instruction manual