//

3

2.0 SUMMARY

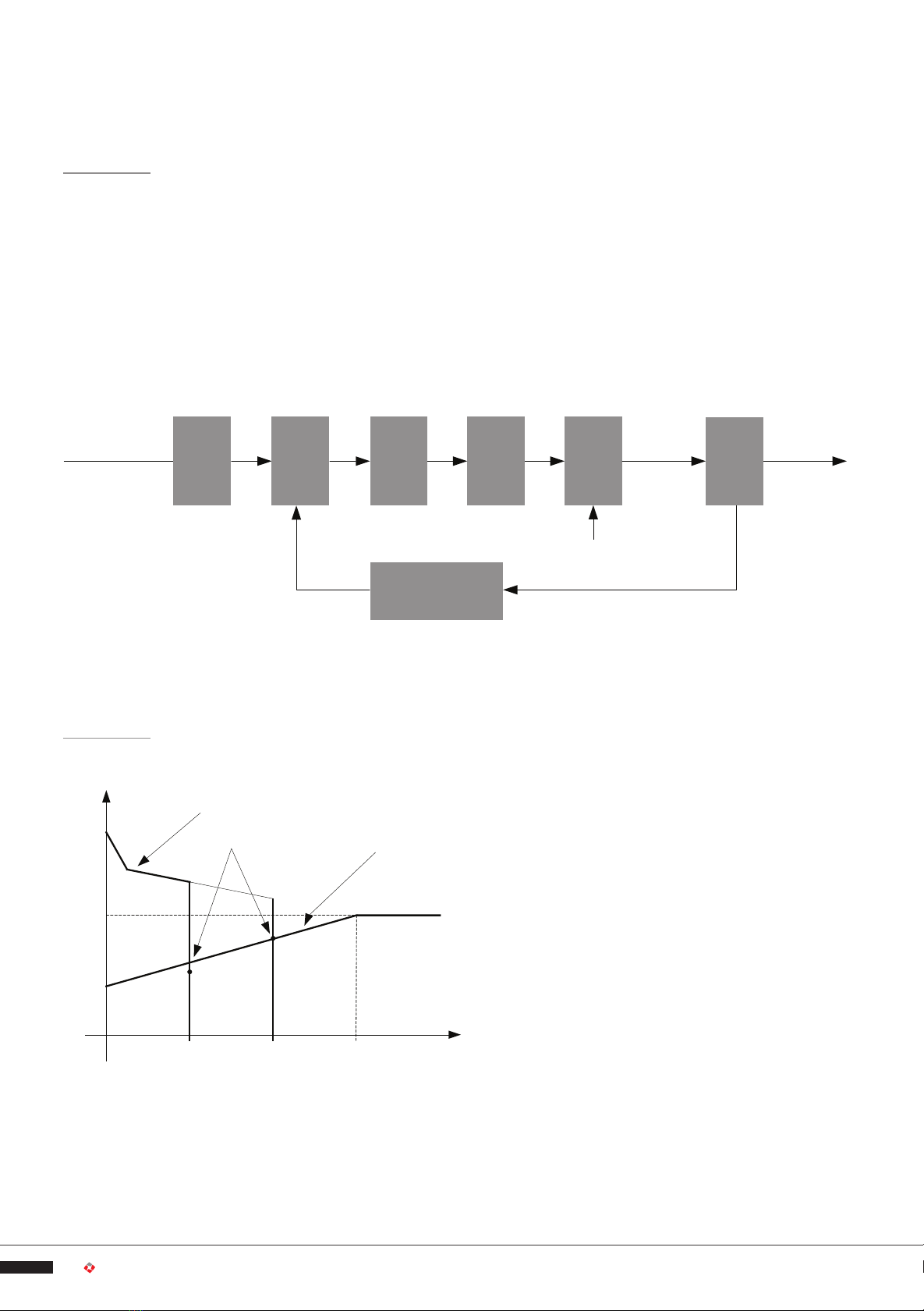

TIG STRIKER 200 AC welding machine adopts the latest pulse width modulation (PWM) technology

and insulated gate bipolar transistor (IGBT) power module, which can change work frequency to

medium frequency so as to replace the traditional hulking work frequency transformer with the

cabinet medium frequency transformer. Thus, it is characterized with portable, small size, light

weight, low consumption etc.

responds immediately to any changes.

power factor more than 0.98

for arc igniting to ensure the success ratio of igniting arc, the

reverse polarity ignition ensures good ignition behavior in TIG-AC welding.

with special means, even if arc-break occurs the HF will keep the arc stable.

If the tungesten electrode touches the workpiece when welding, the

current will drop to short-circuit current to protect tungsten.

over-voltage, over-current, and over heat indication light on the front

panel will turn on and the output current will be cut o. It can self-protect and prolong the life

of the machine.

AC inverter TIG/STICK and DC inverter TIG/STICK, Excellent performance on

Al-alloy, carbon steel, stainless steel, titanium.

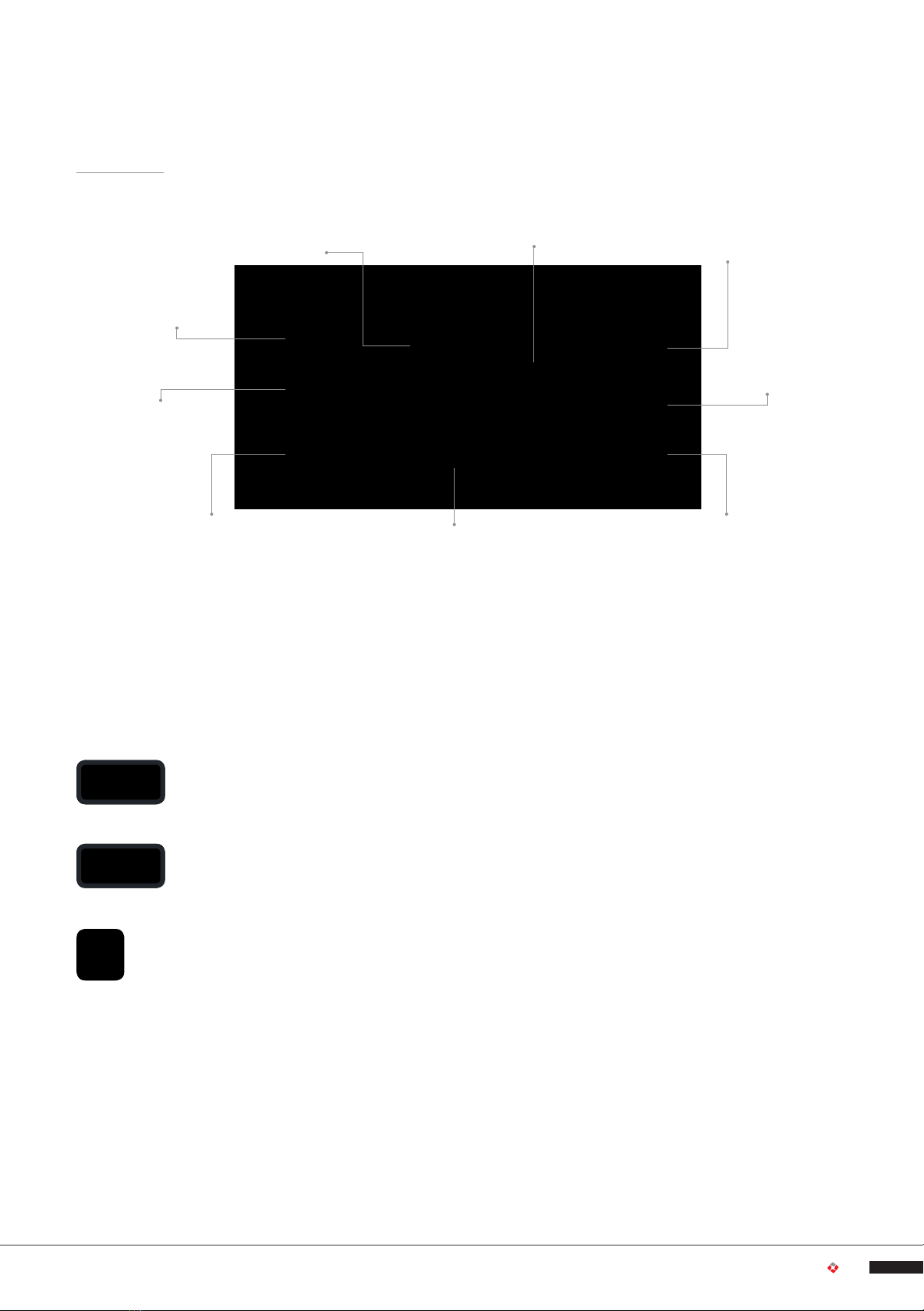

According to the front panel functions, the following six welding modes can be performed:

• DC STICK

• DC TIG

• AC STICK

• AC TIG

1. For DC STICK, polarity connection can be chosen according to dierent electrodes, please

refer to 3.5;

2. For AC STICK, magnetic ow caused by invariable DC polarity can be avoided;

3. For DC TIG, DCEN is used normally (workpiece connected to positive polarity, while torch

connected to negative polarity). This connection has many advantages, such as stable welding

arc, low tungsten pole loss, more welding current, narrow and deep weld;

4. For AC TIG (rectangle wave), arc is more stable than Sine AC TIG. At the same time, you can

not only obtain the max penetration and the min tungsten pole loss, but also obtain better

cleaning eect.

TIG STRIKER 200 AC welding machine is suitable for all positions welding for various plates made

of stainless steel, carbon steel, alloyed steel, titanium, aluminum, magnesium, cuprum, etc.,

which is also applied to pipe installment, mold mend, petrochemical, architecture decoration,

car repair, bicycle, handicraft and common manufacture.

MMA Manual Metal Arc welding;

PWM Pulse-Width Modulation;

IGBT Insulation Gate Bipolar Transistor

TIG Tungsten Insert Gas welding