Bus node

CTEU-CP

Festo AG & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

Description

Installation and interfaces

8029686

1502NH

[8029688]

Original: de

Bus node CTEU-CP English.............................................

1 Notes relating to this description

This description includes information for mounting the bus node on an I-port-com

patible device from Festo (e.g. valve terminal with I-port interface) and for installa

tion of this combination in a higher-level control system.

Information about the CP system can be found in the CP system description

(P.BE-CPSYS-...) and in the description for the electrical interface

CPX-CP-4-FB (P.BE-CPX-CP-...). These documents can also be found online.

èwww.festo.com/sp

TORX®is a registered trademark of its respective trademark holder in

certain countries.

2 Intended use

The bus node type CTEU-CP has been designed exclusively for use as a slave on the

CP bus. It may only be used in its original status without unauthorised modifica

tions and only in perfect technical condition.

The bus node is intended for use in an industrial environment. Outside of industrial

environments, e.g. in commercial and mixed-residential areas, actions to suppress

interference may have to be taken.

3 Target group

The target group of this description consists of trained specialists in control and

automation technology who have experience with installation of slaves on the CP

bus.

4 Mounting

Warning

Risk of injury to people, damage to the machine and system resulting from un

controlled movements of the actuators and undefined switching states

Switch off the operation and load voltage supplies.

Switch off the compressed air supply.

Exhaust the valve terminal pneumatics.

Note

Damage to the electronics

The bus node includes electrostatically sensitive devices.

Do not touch any components.

Observe the handling specifications for electrostatically sensitive devices.

Note

Use cover caps to seal unused connections. The IP65/IP67 degree of protection

is thereby ensured.

Information on mounting the bus node on the decentralised electrical

connecting plate CAPC-... can be found in the mounting instructions that

accompany the connecting plate.

For mounting the bus node on a valve terminal with I-Port interface, proceed as

follows:

1. Inspect the seals and sealing surfaces on the bus node and valve terminal.

2. Push the bus node onto the valve terminal in the correct position with no tilt.

3. Screw in the three self-tapping screws. When screwing the screws in again, use

existing threads.

4. Tighten the screws in a diagonally opposite sequence with a tightening torque

of 0.7 ± 0.1 Nm.

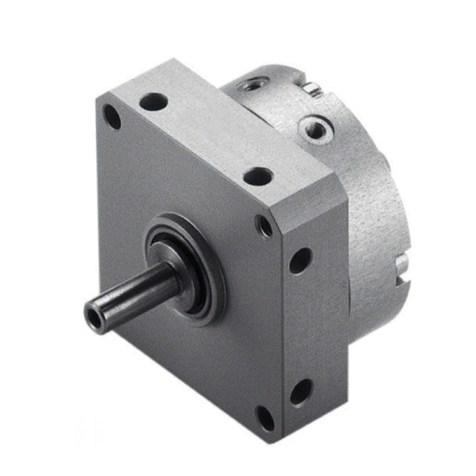

5 Connection and display components

The following electrical connection and display components can be found on the

bus node:

1

3

4

2

1DIL switch (èChap. 7.2)

2Status LEDs (status display/

diagnostics èChap. 8)

3M9 plug, CP connection and

incoming power supply (èChap. 6)

4M9 socket, CP connection and

continuing power supply

(èChap. 6)

Fig. 1

6 Connecting the CP bus and load voltage

The bus node has a signal and load voltage supply. It also supplies voltage to the

devices connected via the I-port interface.

If the continuing CP connection is not used, the cover cap must be mounted to

ensure the IP65/IP67 degree of protection.

Screw the cover cap by hand until it noticeably engages against the stop.

The bus node is supplied with the cover cap already mounted.

Warning

Danger of electric shock

For the electrical power supply, use only PELV voltage sources in accordance

with IEC 60204-1 (Protective Extra-Low Voltage, PELV).

Observe the requirements of IEC 60204-1 for PELV circuits.

Through the use of PELV circuits, protection against electric shock (protection

against direct and indirect contact) is ensured in accordance with IEC 60204-1.

When using external connecting cables, please note:

– The maximum length of the external connecting cable to a valve terminal is 15 m.

Note

Electromagnetic interference

Establish the connection to the functional earth via the connected device or

the electrical connecting plate CAPC-....