2

Contents

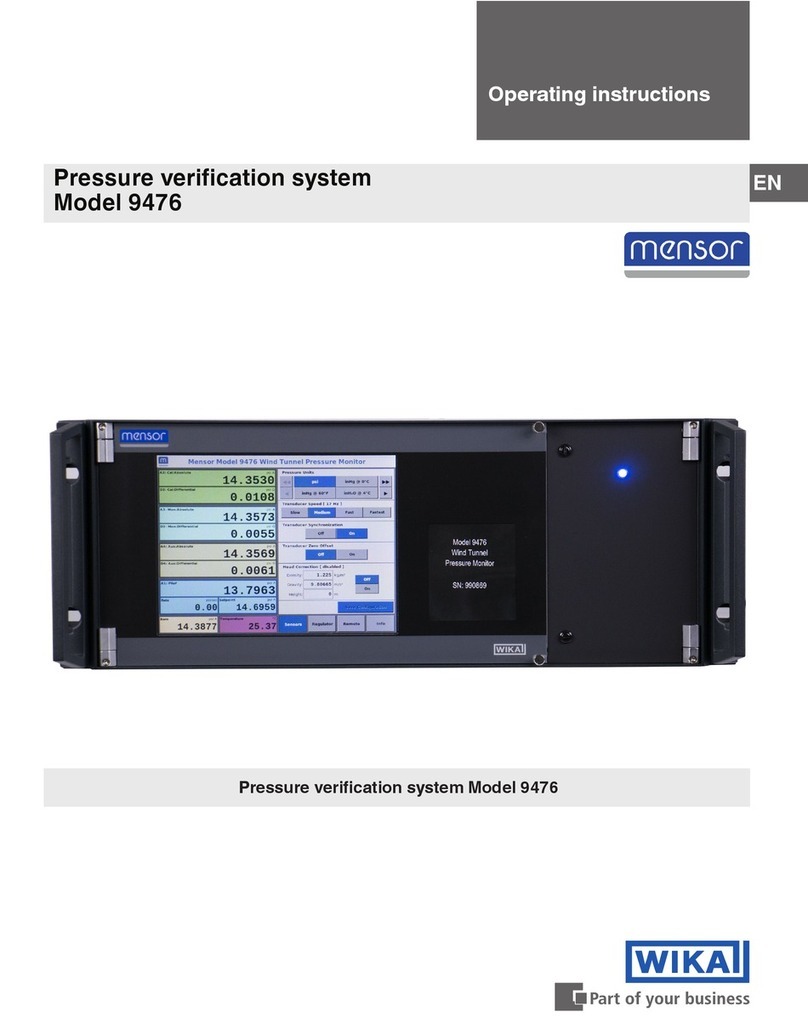

WIKA Operating Instructions - Dierential pressure transmitter DPT-10

Contents

1 About this document

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbolism used ............................................................................................................... 4

2 For your safety

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use ................................................................................................................ 5

2.3 Warning about incorrect use ............................................................................................. 5

2.4 General safety instructions ............................................................................................... 5

2.5 Safety label on the instrument .......................................................................................... 5

2.6 CE conformity ................................................................................................................... 6

2.7 Fulllment of NAMUR recommendations ......................................................................... 6

2.8 Safety instructions for oxygen applications ....................................................................... 6

3 Product description

3.1 Conguration .................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Adjustment ..................................................................................................................... 11

3.4 Packaging, transport and storage ................................................................................... 11

4 Mounting

4.1 General instructions to use the instrument ..................................................................... 13

4.2 Instructions for oxygen applications ............................................................................... 14

4.3 Mounting and connection instructions ............................................................................ 14

4.4 Measurement setup ow ................................................................................................ 18

4.5 Measurement setup level ............................................................................................... 21

4.6 Measurement setup density and interface ...................................................................... 25

4.7 Measurement setup dierential pressure ....................................................................... 27

4.8 Mounting external housing ............................................................................................. 29

4.9 Installation control .......................................................................................................... 30

5 Connecting to power supply

5.1 Preparing the connection ............................................................................................... 31

5.2 Connection procedure .................................................................................................... 32

5.3 Single chamber housing ................................................................................................. 33

5.4 Double chamber housing ............................................................................................... 34

5.5 Double chamber housing Ex d ....................................................................................... 37

5.6 Version IP 66/IP 68, 1 bar ............................................................................................... 38

5.7 Switch-on phase............................................................................................................. 39

6 Adjustment with the display and adjustment module

6.1 Short description ............................................................................................................ 40

6.2 Insert display and adjustment module ............................................................................ 40

6.3 Adjustment system ......................................................................................................... 41

6.4 Set parameters ............................................................................................................... 42

6.5 Menu schematic ............................................................................................................. 52

6.12 Saving the parameter adjustment data ........................................................................... 55

7 Setup with the adjustment program AMS™

7.1 Parameter adjustment with AMS™................................................................................. 56