Contents

1. Safety instructions

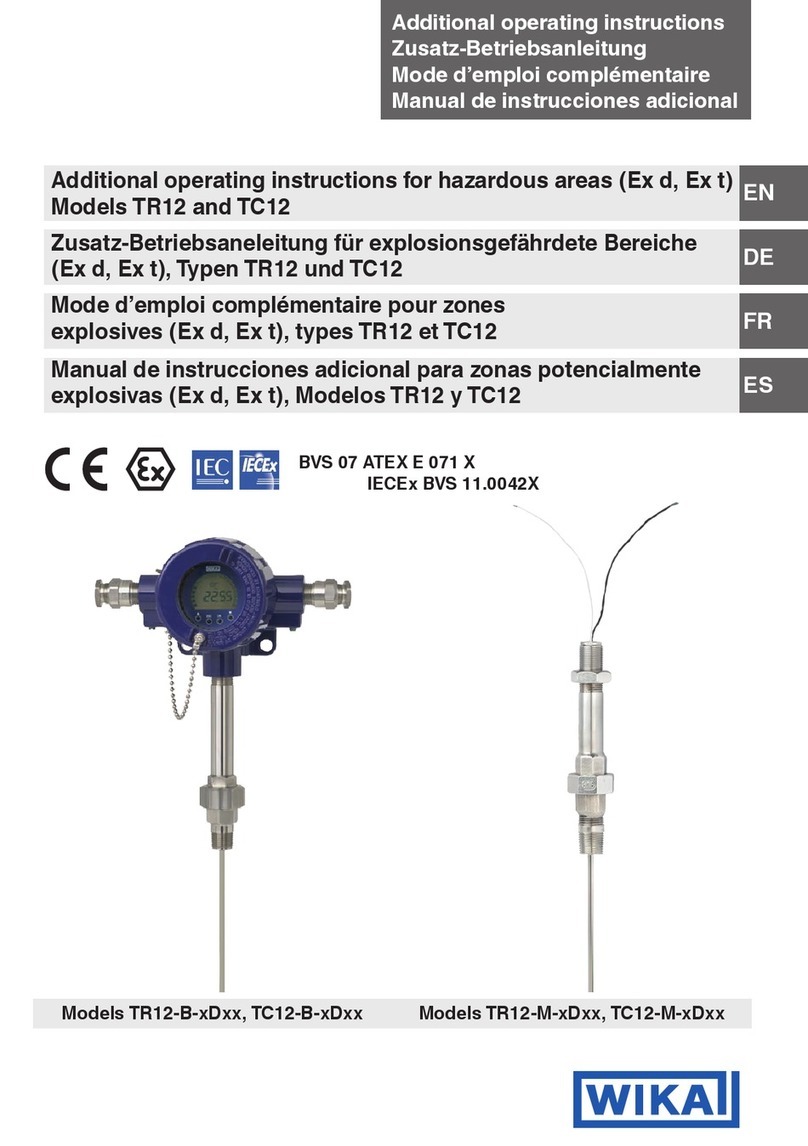

2. Description, Application

3. Mechanical connection

3.1 Special requirements for the installation point

4. Wiring details

5. To set desired value indicator

6. Ingress protection IP

7. Admissible ambient temperatures

8. Maintenance and servicing/Cleaning

9. Repairs

10. Power ratings

11. Overcurrent protection devices

12. Switch version appropriate to gauge type

and range

Electrical alarm contacts

with Magnetic snap-action or Sliding contacts

in pressure and temperature gauges

Pressure Gauge

Model 212.20.100

Operating

Instructions

GB

1. Safety instructions

The appropriate national safety regulations

(i.e. VDE 0100) must be observed when installing,

putting into operation and running these

instruments.

Do not work on gauge while under voltage.

Serious injuries and/or damage can occur should

the appropriate regulations not be observed.

The gauges are no safety accessories as defined by the

Pressure Equipment Directive 97 / 23 / EC.

Only appropriately qualified persons should work on these

instruments.

2. Description, Application

The built-in electric alarm contacts (magnetic snap-action or

sliding) are auxiliary current switches which open and close

the connected electrical circuits at the set points via the

contact arm, which is driven by the main instrument pointer.

3. Mechanical connection

According to the general technical regulations for pressure

gauges and temperature measuring instruments, respectively

(i.e. EN 837-2 or EN 13 190). When screw-fitting the gauges

the force required for this must not be applied through the

case or terminal box but just through the spanner flats (with

suitable tool) provided for this purpose.

Installation with

open-end wrench

With safety pattern gauges (see dial symbol k) you need to

pay attention to the fact that the free space behind the blow-

out back will be at least 15 mm.

3.1 Special requirements for the installation point

Instruments must be mounted in a location free from

vibration in order to avoid contact chatter and the resulting

increased wear. If the measuring point is not adequately

stable a measuring instrument holder should be used for

fastening (and possibly via a flexible capillary line). If the

pressure gauge is exposed to vibration or pulsating pressure

or both, then a liquid filled pressure gauge may provide

considerably better performance and readability.

Instruments should be protected against coarse dirt and

wide fluctuations in ambient temperature.

4. Wiring details

The electrical connections should be made by qualified

electricians. Connection details and switch functions are

given on the instrument type plate. Connection terminals and

ground terminal are appropriately marked.

The mains connection lines to be provided must be

dimensioned for maximum instrument power consumption

and comply with IEC 227 or IEC 245.

Power ratings and overcurrent protection devices see

overleaf.

5. To set desired value indicator

The desired value indicators for the alarm contacts are

adjustable over the adjustment lock in the window with

the aid of adjustment key (included in delivery; to be found

on standard gauges on the outside edge of the junction box).

The desired value indicators for the alarm contacts are

adjustable over the full range of the instrument. Switching

points shall be set in the ranges between 10 % and 90 % of

the scale, to ensure switching accuracy and long life of the

mechanical measuring system.

6. Ingress protection IP

The type of enclosure to EN 60 529 for protection against

external influences depends on the basic instrument and is

found in the respective data sheet.

7. Admissible ambient temperatures

The permissible ambient temperatures for alarm contacts is

-20 to +70°C. Where this span exceeds the permissible

temperature limits for the instrument to which the contacts

are fitted, the limits for the instrument apply (see data sheet).

8. Maintenance and servicing / Cleaning

The instruments require no maintenance or servicing.

The indicator and switching function should be checked

once or twice every 12 months. The instrument must be

disconnected from the process to check indication with a

pressure or temperature testing device.

The instruments should be cleaned with a damp cloth

moistened with soap solution. For cleaning inside the

instrument the mains power supply should be disconnected

by means of the plug box or plug connection.

It must be ensured that all the parts are dry before the power

is switched on again.

9. Repairs

Repairs are to be only carried out by the manufacturer or

appropriately trained personnel.

For further details see WIKA data sheet AC 08.01 or the type

sheet for the respective basic gauge.

Examples:

Thermometer

Model 55

Adjustment key

removable

Desired value

indicators

(red set pointer)

Adjustment lock