2

3

83795208.01 04/2022 EN

WIKA operating instructions, flow switch, model FSFD

WIKA operating instructions, flow switch, model FSFD

3.2 Intended use

The model FSFD was developed to detect ow in wet sprinkler systems once the

sprinkler has been triggered.The pneumatic time delay can be adjusted on-site between

0 ... 70 seconds via an adjustment dial to avoid false alarms during water surges.The

instrument can switch electrical loads of up to AC 250 V, 10 A.

WARNING!

Injuries due to incorrect application

Use in an incorrect application can result in considerable injury and damage to

property.

▶If the valves controlling the water supply to a sprinkler system are closed,

the vane-type flow switches will not operate.All valves controlling the water

supply to a sprinkler system should be sealed or locked in the normally open

position.The normally open position should be monitored by a sprinkler

system monitoring switch.

▶Flow switches may not work, or may not work properly, if the sprinkler pipes

being monitored are blocked with deposits from slurries, stones or other

foreign objects. Sprinkler systems should be checked periodically for such

blockages, following the instructions in chapter 5 of NFPA standard 13A.

▶Only use the instrument in applications that lie within its technical perfor-

mance limits (e.g. max. ambient temperature, material compatibility, ...). For

performance limits, see chapter 9 “Specifications”.

▶Flow switches are not a substitute for insurance. Building owners should

always insure property and life which is protected by the sprinkler systems.

This instrument is not permitted to be used in hazardous areas!

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

3.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and injuries.

▶Refrain from unauthorised modifications to the instrument.

▶Do not use the instrument within hazardous areas.

▶Do not use the instrument with abrasive or corrosive media.

Flow switches monitoring wet sprinkler systems must not be used to discharge

aqueous film-forming foam (AFFF), sprayed water or chemical suppression systems.

Flow switches used for these applications can result in false readings caused by water

surges, air pockets, etc.

Any use beyond or different to the intended use is considered as improper use.

3.4 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient!

Improper handling can result in considerable injury and damage to property.

▶The activities described in these operating instructions may only be carried

out by skilled personnel who have the qualifications described below.

Skilled electrical personnel

Skilled electrical personnel are understood to be personnel who, based on their technical

training, know-how and experience as well as their knowledge of country-specific regula-

tions, current standards and directives, are capable of carrying out work on electrical

systems and independently recognising and avoiding potential hazards.The skilled electri-

cal personnel have been specifically trained for the work environment they are working in

and know the relevant standards and regulations.The skilled electrical personnel must

comply with current legal accident prevention regulations. Special operating conditions

require further appropriate knowledge, e.g. of aggressive media.

3.5 Labelling, safety marks

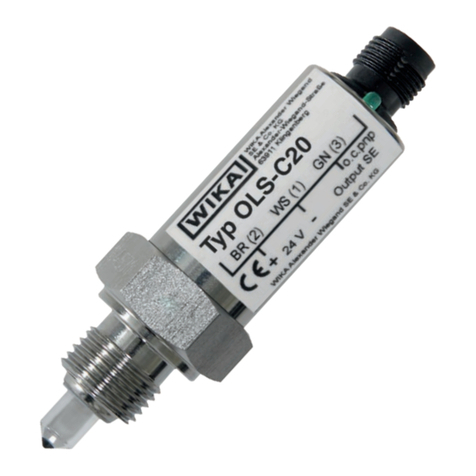

Product label (example)

Manufacturer's address Flow rate

Date of manufacture Pipe size

Ingress protection Article number

Electrical rating Serial number

Operating pressure Approvals

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

4. Transport, packaging and storage

4.1 Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶When unloading packed goods upon delivery as well as during internal

transport, proceed carefully and observe the symbols on the packaging.

▶With internal transport, observe the instructions in chapter

4.2 “Packaging and storage”.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction.Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

Permissible conditions at the place of storage:

■Storage temperature: 0 ... 68 °C [32 ... +154 °F]

■Humidity: 35 ... 85 % relative humidity (no condensation)

Avoid exposure to the following factors:

■Direct sunlight or proximity to hot objects

■Mechanical vibration, mechanical shock (putting it down hard)

■Soot, vapour, dust and corrosive gases

■Hazardous environments, flammable atmospheres

Store the instrument in its original packaging in a location that fulfils the conditions listed

above.

5. Commissioning, operation

Familiarise yourself with the following guidelines before installation:

■NFPA 72: National fire alarm and signaling code

■NFPA 13: Installation of sprinkler systems, section 3.17

■NFPA 25: Inspection, testing and maintenance of sprinkler systems, section 5.3.3.2

■Other applicable NFPA guidelines, local regulations and requirements of the compe-

tent authority