Wilbur Curtis Company CAFE 1DB User manual

1

FIND OUT MORE

ON

THE WEB.

WILBU RCURTIS.COM

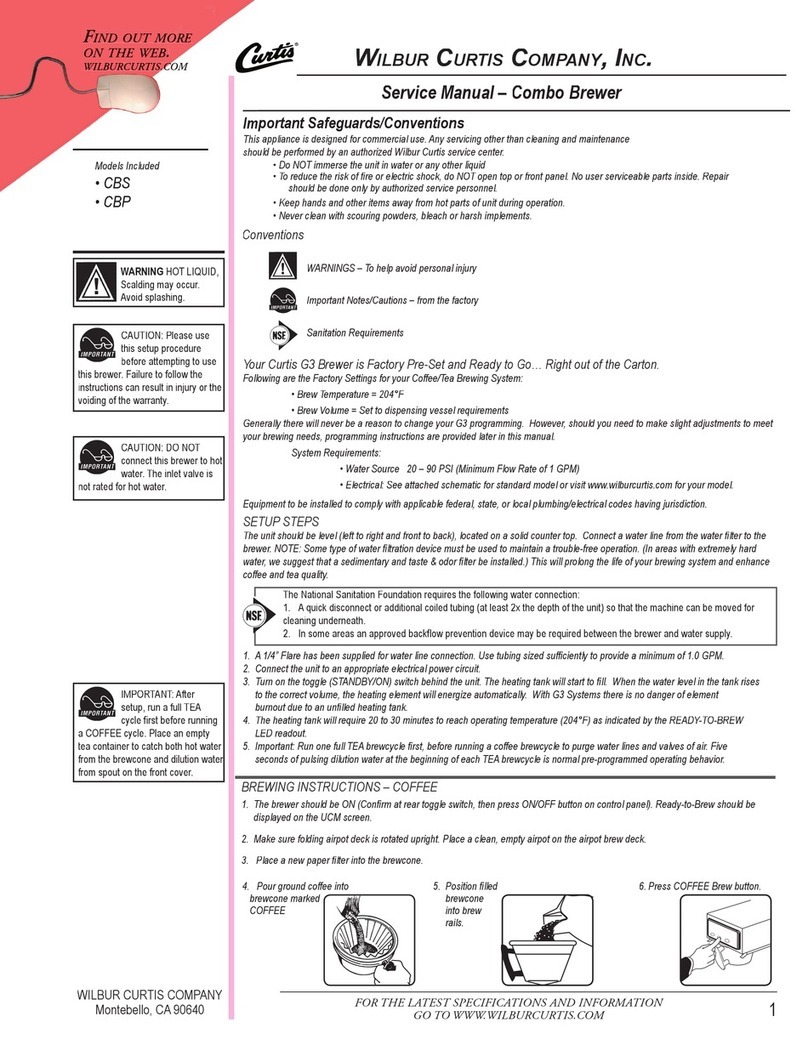

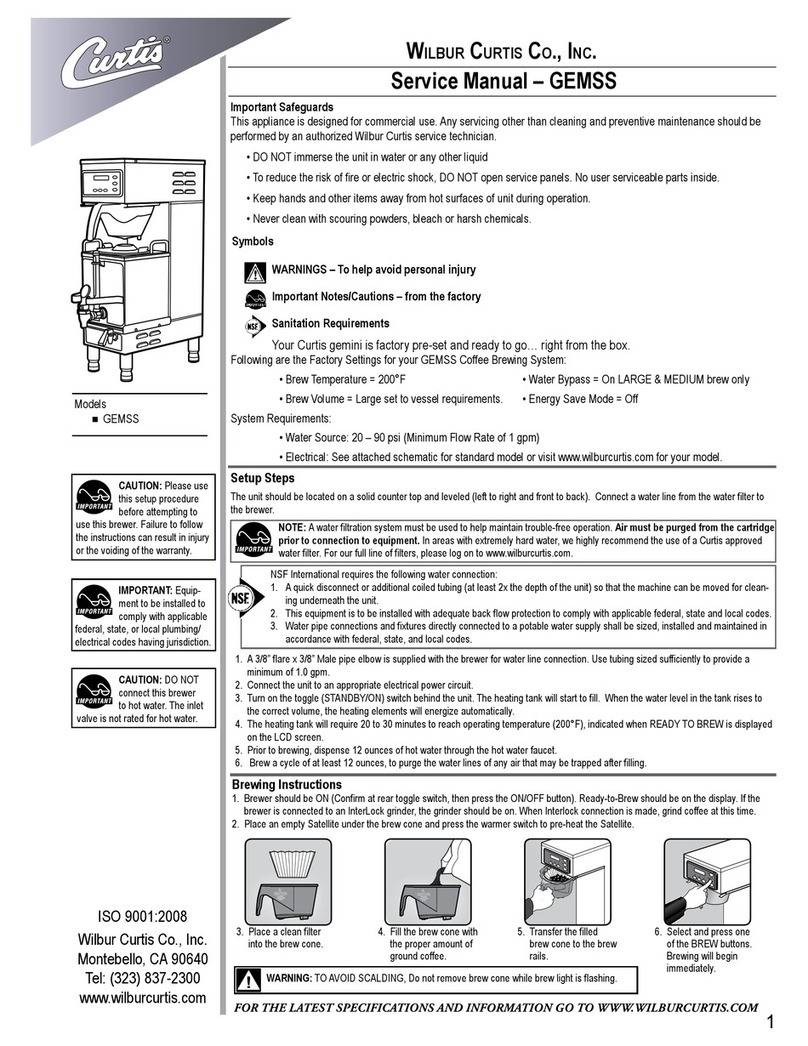

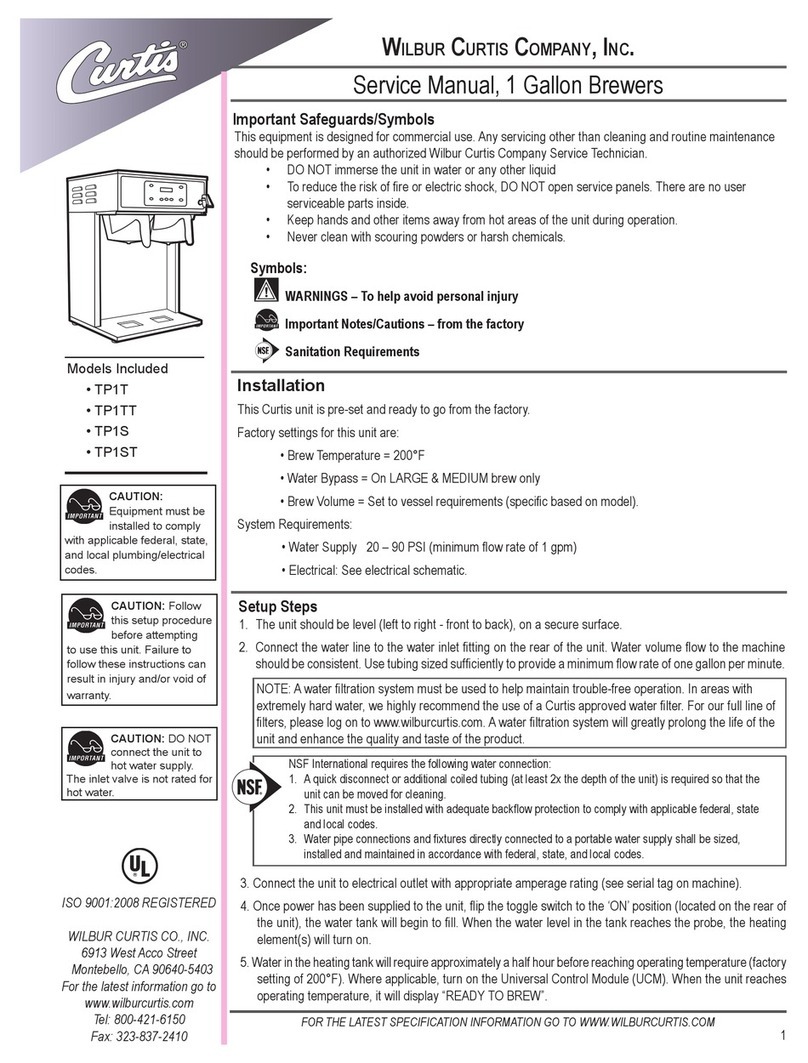

WILBUR CURTIS COMPANY, INC.

MODELSINCLUDED

•CAFE 1DB

•CAFE 2DB

•CAFE 3DB

•CAFE AP

•CAFE 2DBS

•CAFE 0PP

ISO9001REGISTERED

C

CAUTION:Please

usethissetup

procedurebeforeattemptingto

usethisbrewer.Failureto

followtheinstructionscan

resultininjuryorthevoidingof

thewarranty.

WARNING: To

avoidscalding,

allowbrewcone

todrainbefore

removing.

SETUP STEPS

1. Placement of brewer should be on a solid,

level counter top, near a 120 VAC outlet

rated at 20 amps.

2. Place an empty glass decanter on the

warmerdeck,underthesprayhead.

3. Insertan empty brewconeintothe brew

rails unit (fig. 1.).

4. Pour water into the pour hole on top of

brewer. When water starts to come from

the brewcone, the tank is full. Stop

pouring.

5. Plug power cord into a 120V electrical

outlet(referenceladderdiagramsonpage3).

6. Allow the brewer to heat up to it’s full temperature, indicated by Ready to Brew light.

This takes about 15 to 25 minutes the first time the coffee brewer

is plugged in. Slight dripping from the brewcone is normal as the

tank heats up. The unit is ready for brewing.

Figure 1. Sprayhead and brewcone rails.

SPRAYHEAD

GUIDE RAILS

BREWING INSTRUCTIONS

1. Pour ground coffee evenly into filter and insert into brewer.

2. Slide brew cone into guide rails (fig. 1.). Place clean decanter

onwarmer plate(use airpotwhen brewing with Café AP).

3.Take another decanter and pour water intothe holeon thetop

cover (fig. 3.). Brewing will take about three minutes.

4. Switch on the warmer plates to keep the coffee at serving

temperature.

Figure 2. Pour ground

coffeeintofilter.

Figure 3. Pour cold

water into pour hole.

NOTE: Youshouldhaveatleasttwodecantersforbrewingcoffee.

Oneforpouringwater,theothertobrewcoffeeinto.Airpotbrewers

willrequireapitcherthatholds74ounces(seefigure3).

NOTE: Duetoevaporation,watermaybelostfromthetankifbreweris

leftonforlongperiodsoftimewithoutmakingcoffee.Whenthisoccurs,

pourinenoughwatertorefilltheheatingtankbeforebrewing.

This appliance is designed for commercial use.Any servicing other than cleaning and

maintenanceshould beperformed by an authorized WilburCurtis servicecenter.

•Do NOT immerse the unit in water or any other liquid

•To reduce the risk of fire or electric shock, do NOTopen top panel. No user ser-

viceable parts inside. Repair should be done only by authorized service personnel.

•Keep hands and other items away from hot parts of unit during operation.

•Never clean with scouring powders or harsh implements.

BREWCONE

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO

W W W.WILBU RC U RTIS.COM

CAUTION- ThisbrewerisshippedwiththethermostatturnedON.DONOTpluginthepowercord

untiltheheatingtankhasfilledwithwater(seestep4,below);damagetotheheatingelementor

thermostatwillresult.

WILBURCURTISCOMPANY

Montebello,CA90640

SERVICE MANUAL - CAFE POUROVER

PARTS

DIAGRAMS

1

2

3

4

5

5A

6

7

8

8A

9

24

20

21

Item Nº Part Nº Description

1 WC-68101 TOP WARMER ASSY, 120V (CAFÉ 2DB)

1A WC-68103 TOP WARMER ASSY, 220V (CAFÉ 2DB)

2 WC-37135 WARMER ASSY 100W 120V w/PLATE

2B WC- 975 WARMER ASSY, COMPLETE 100W 220V

3** WC-54118 TRAY ASSY POUROVER

4** WC-54121 PAN, POUR CAFE’

5** WC- 517 * THERMOSTAT

5A WC- 735 THERMOSTAT, TEMP CONTROL 120V

6 WC-2962* FITTING, SPRAYHEAD

7 WC-4213 NUT, 5/8-18 JAM BRASS

8** WC-2958* SPRAYHEAD, BROWN

8A** WC-29025 SPRAYHEAD, PURPLE ASF

9 WC-3502 LEG, SCREW BUMPER

10 WC-38099* LABEL, SW PANEL CAFÉ 2DB

10A WC-38113* LABEL, SW PANEL CAFÉ 1DB

10B WC-38114* LABEL, SW PANEL CAFÉ 3DB

10C WC-38127* LABEL, SW PANEL CAFÉ AP

10D WC-39373 LABEL, SW PANEL CAFÉ 2DB (ON/OFF SW)

10E WC-39372 LABEL, SW PANEL CAFÉ 1DB (ON/OFF SW)

10F WC-39374 LABEL, SW PANEL CAFÉ 3DB (ON/OFF SW)

10G WC-39371 LABEL, SW PANEL CAFÉ AP (ON/OFF SW)

10H WC-38413 LABEL, SW PANEL CAFE 2DBS

11** WC- 165 SWITCH, WARMER RED 115V

11A WC- 137 SWITCH, WARMER RED 220V

12 WC- 207 LIGHT, BREW 115V GREEN

12A WC- 208 LIGHT, BREW 250V GREEN

13 WC-3621 CONE, UNIV BREW 7.1” BLK PLASTIC

14** WC-5310 TUBE, 5/16 ID X 1/8 W SILICONE

15 WC-29042 HOSE, VENTILATION HEATING TANK

16 WC-2627 GROMMET, COVER HEATING TANK

17 WC-54125* COVER, TOP HEATING TANK

17A WC-54125-101 COVER, TOP HEATING TANK

18 WC-43062 GASKET, TANK LID

19 WC-54117 TANK, COMPLETE 1450W 120V

19A WC-54145 TANK, COMPLETE 3500W 240V

20 WC- 935* ELEMENT, HEATING 1.45kW 120V

20A WC- 917-04 ELMNT, HEAT1.45kw 120V W/NTS & WSHRS

20B WC- 936* ELEMENT, HEATING 3.5KW 240VAC

20C WC- 922-04 ELEMENT, HEATING 3.5KW 220V

21** WC- 523* THERMOSTAT, MANUAL RESET

21A WC- 521 THERMOSTAT, AUTO RESET

22** WC-29054 TUBE, CAFÉ SPRAYHEAD/SYPHON

23 WC-3645 SPRING, DELIMING CAFE SERIES

24 WC-73106 COVER, BOTTOM

25 WC-68102 COVER ASSY, TOP (CAFÉ 1DB, 3DB, AP)

24

2

14

15

16

17

18

19

*Component Used on Older Units

** Suggested Parts to Stock

10

11

12

13

22

23

NOTE: Items, called out in this illustration, are

specific to Cafe 1DB, Cafe 3DB & Café AP.

All other parts are common.

10H

10A

10D

10B

10E

10C

10F

DELIMINGSPRING Thisspringis

for cleaning lime deposits from

within the siphon tube.

Remove the sprayhead. Insert

spring into the siphon tube.

Twist the spring clockwise as

you push inward. Once past the

bend in the tubing, you can

slide it back an forth to remove hard lime deposits.

ELECTRICALLADDERDIAGRAMS

Brewer Model Café 1DB, 2DB, 2DBS, 3DB & AP (All 120VAC Units)

Table1. MODEL&ELECTRICAL(All120VACUnits)

Brewer Model Café 1DB, 2DB, 3DB & AP (All 208-240VAC Units)

Table2. MODEL&ELECTRICAL(All208-240VACUnits) “ExportOnly”

3

MODEL CIRCUIT VOLTS WATTS

A

MPS HERTZ WIRE PHASE

CAFE0AP10 WC-917 A 120VAC 1450W 12.1A 50/60HZ 2W + G 1-PHASE

CAFE1DB10 WC- 917 A + B 120VAC 1550W 12.9A 50/60HZ 2W + G 1-PHASE

CAFE2DB10 WC- 917 A + B + C 120VAC 1650W 13.8A 50/60HZ 2W + G 1-PHASE

CAFE2DBS10 WC- 917 A + B + C + E 120VAC 1650W 13.8A 50/60HZ 2W + G 1-PHASE

CAFE3DB10

CAFE0PP10

WC- 917

WC- 917

A + B + C + D

A

120VAC

120VAC

1750W

1450W

14.6A

12.1A

50/60HZ

50/60HZ

2W + G

2W + G

1-PHASE

1-PHASE

CAFE1DB20 WC- 933 A + B 120VAC 1250W 10.4A 50/60HZ 2W + G 1-PHASE

CAFE2DB20 WC- 933 A + B + C 120VAC 1350W 11.3A 50/60HZ 2W + G 1-PHASE

CAFE3DB20 WC- 933 A + B + C + D 120VAC 1450W 12.1A 50/60HZ 2W + G 1-PHASE

HEATING

ELEMENT

LD-CAFE-10 rev Q

MODEL HEATING

ELEMENT CIRCUIT VOLTS WATTS AMPS

CAFE0AP30 WC-922 A 208 - 240VAC 2629 - 3500W 12.6 - 14.6A

CAFE1DB30 WC-922 A + B 208 - 240VAC 2704 - 3600W 13.0 - 15.0A

CAFE2DB30 WC-922 A + B + C 208 - 240VAC 2779 - 3700W 13.4 - 15.4A

CAFE3DB30 WC-922 A + B + C + D 208 - 240VAC 2854 - 3800W 13.7 - 15.8A

MODEL AND ELECTRICAL TABLE

D

C

B

2WHT

1

BRN

RED STP

2

BLK 3

1

BLK 213

100W, 120VAC

1

WARMER ELEMENT

2

RED 12

WHT

WHT

WHT

WHT

WARMER SW

120V NEON

BLK 213WHT

WARMER ELEMENT

100W, 120VAC

WARMER ELEMENT

100W, 120VAC

120V NEON

WARMER SW

120V NEON

WARMER SW

BLK

A

WHT #14

YEL BLU #14 12

WHT #14

BLK

HI-LIMIT (220°F)

120/240VAC 25A

SEE TABLE FOR RATING

120V (GREEN) NEON

HEATING TANK

TEMPERATURE

SENSOR

THERMOSTAT,

TEMPERATURE

120/220VAC

HEATING TANK

BREW LIGHT

WHT #14

BLK #14

BLK #14

L1

WHT #14

N

NO NC

COM

WC-735

WHT/YEL

WHT/YEL

BLK #14

200°F SET POINT

E

BLK

125V 15A

WHT

RECEPTACLE

MAX. LOAD 2A

REAR

WARMER

TOP/FRONT

WARMER

BOTTOM

WARMER

Printed in U.S.A. 9/06 F-3215-S Rev H

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO WWW.WILBURCURTIS.COM

9/27/6 . 8.7 . ecn 8539

8/10/6 . 14.9 . ecn 8415

7/31/6 ecn 8390 rev F

5/5/5 ecn 7510 rev E

10/6/04 ecn 7094 Rev D

4

WILBURCURTISCO.,INC.

6913AccoSt.,Montebello,CA90640-5403USA

Phone:800/421-6150 Fax: 323-837-2410

Web Site:www.wilburcurtis.com

ProductWarrantyInformation

The Wilbur Curtis Company certifies that its products are free from defects in material and workmanship under normal use. The following limited

warrantiesandconditionsapply:

3Years,PartsandLabor,fromOriginalDateofPurchaseondigitalcontrolboards.

2Years,Parts,fromOriginalDateofPurchaseonallotherelectricalcomponents,fittingsandtubing.

1Year,Labor,fromOriginalDateofPurchaseonallelectricalcomponents,fittingsandtubing.

Additionally,theWilburCurtisCompanywarrantsitsGrindingBurrsforForty(40)monthsfromdateofpurchaseor40,000poundsofcoffee,whichever

comesfirst. StainlessSteelcomponentsarewarrantedfortwo(2)yearsfromdateofpurchaseagainstleakingorpittingandreplacementpartsare

warrantedforninety(90)daysfromdateofpurchaseorfortheremainderofthelimitedwarrantyperiodoftheequipmentinwhichthecomponentis

installed.

Allin-warrantyservicecallsmusthavepriorauthorization. ForAuthorization,calltheTechnicalSupportDepartmentat1-800-995-0417. Effectivedate

ofthispolicyisApril1,2003.

Additionalconditionsmayapply. Gotowww.wilburcurtis.comtoviewthefullproductwarrantyinformation.

CONDITIONS&EXCEPTIONS

Thewarrantycoversoriginalequipmentattimeofpurchaseonly.TheWilburCurtisCompany,Inc.,assumesnoresponsibilityforsubstitutereplacement

partsinstalledonCurtisequipmentthathavenotbeenpurchasedfromthe

WilburCurtisCompany,Inc. TheWilburCurtisCompanywillnotacceptanyresponsibilityifthefollowingconditionsarenotmet.Thewarrantydoesnot

coverandisvoidunderthefollowingcircumstances:

1) Improper operation of equipment: Theequipmentmust be usedforits designedandintended purpose andfunction.

2) Improperinstallation of equipment: Thisequipmentmustbeinstalledbyaprofessionaltechnicianandmustcomplywithalllocalelectrical,

mechanicalandplumbingcodes.

3) Impropervoltage: Equipmentmustbeinstalledatthevoltagestatedontheserialplatesuppliedwiththisequipment.

4) Improperwatersupply: Thisincludes,butisnotlimitedto,excessiveorlowwaterpressure,andinadequateorfluctuatingwaterflowrate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the

responsibilityoftheequipmentowner. Theownerisresponsibleforpropercleaningandregularmaintenanceofthisequipment.

6) Damagedin transit: Equipmentdamagedintransitistheresponsibilityofthefreightcompanyandaclaimshouldbemadewiththecarrier.

7) Abuseorneglect(includingfailuretoperiodicallycleanorremovelimeaccumulations): Manufacturerisnotresponsibleforvariationin

equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

8) Replacement of items subject to normal use and wear: Thisshallinclude,but is notlimitedto,light bulbs, sheardisks,“0”rings, gaskets,

siliconetube,canisterassemblies,whipperchambersandplates,mixingbowls,agitationassembliesandwhipperpropellers.

9) Repairsand/orReplacementsaresubjecttoourdecisionthattheworkmanshiporpartswerefaultyandthedefectsshowedupundernormal

use. Alllaborshallbeperformedduringregularworkinghours.Overtimechargesaretheresponsibilityoftheowner. Chargesincurredbydelays,

waitingtime,oroperatingrestrictionsthathindertheservicetechnician’sabilitytoperformserviceistheresponsibilityoftheowneroftheequip-

ment. This includes institutional and correctional facilities. The Wilbur Curtis Company will allow up to 100 miles, round trip, per in-warranty

servicecall.

RETURNMERCHANDISEAUTHORIZATION: AllclaimsunderthiswarrantymustbesubmittedtotheWilburCurtisCompanyTechnicalSupport

Departmentpriortoperforminganyrepairwork orreturn of this equipment to the factory. Allreturnedequipmentmustberepackagedproperlyin

theoriginalcarton.Nounitswillbeacceptediftheyaredamagedintransit due to improper packaging. NO UNITS OR PARTS WILLBEAC-

CEPTEDWITHOUTARETURNMERCHANDISEAUTHORIZATION(RMA). RMANUMBER MUSTBEMARKED ONTHECARTONOR

SHIPPINGLABEL. Allin-warrantyservicecallsmustbeperformedbyanauthorizedserviceagent. CalltheWilburCurtisTechnicalSupport

Departmenttofindanagentnearyou.

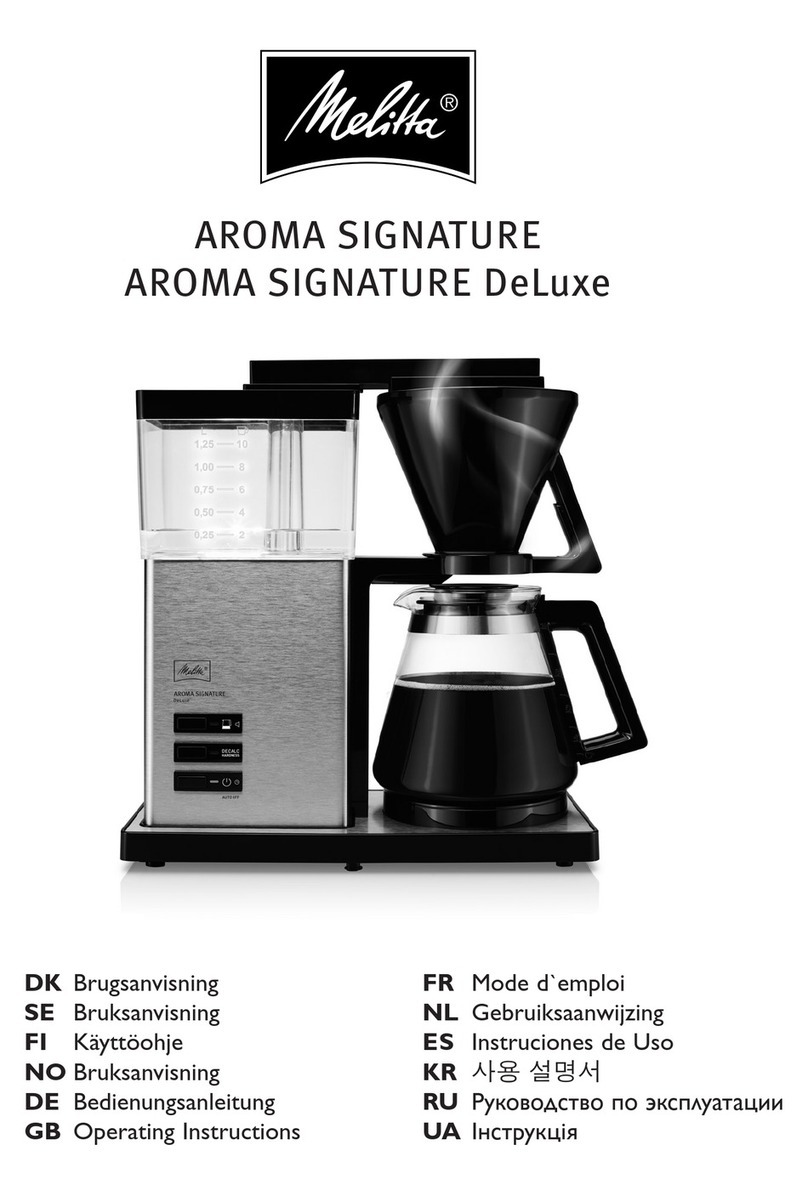

This manual suits for next models

1

Table of contents

Other Wilbur Curtis Company Coffee Maker manuals

Wilbur Curtis Company

Wilbur Curtis Company CBS User manual

Wilbur Curtis Company

Wilbur Curtis Company GEM SS User manual

Wilbur Curtis Company

Wilbur Curtis Company TP1T User manual

Wilbur Curtis Company

Wilbur Curtis Company D60GT User manual

Wilbur Curtis Company

Wilbur Curtis Company D500GT User manual

Wilbur Curtis Company

Wilbur Curtis Company ThermoPro TP2T User manual

Wilbur Curtis Company

Wilbur Curtis Company Brewer User manual

Wilbur Curtis Company

Wilbur Curtis Company Curtis CGC User manual

Wilbur Curtis Company

Wilbur Curtis Company G4 ThermoPro G4TP2T User manual

Wilbur Curtis Company

Wilbur Curtis Company CA 90640 User manual