Page 7 of 11 Revision: CT/Feb-/2020

4. Maintenance Instructions

4.1 Lubrication

Proper lubrication is the owner's responsibility. Failure to lubricate the air tool properly will dramatically

shorten the life of the tool and will void the warranty.

This impact wrench requires lubrication before the initial use and

before and after each additional use.

4.2 Impact wrench require lubrication throughout the life of the tool and must be lubricated in two separate areas:

the air motor and the impact mechanism.

4.3 Air Motor Lubrication

4.3.1 The motor must be lubricated daily. An air motor cannot be oiled too often.

Disconnect the impact wrench from the air supply before lubricating.

4.3.2 Disconnect the impact wrench from the air supply.

4.3.3 Turn the impact wrench upside down.

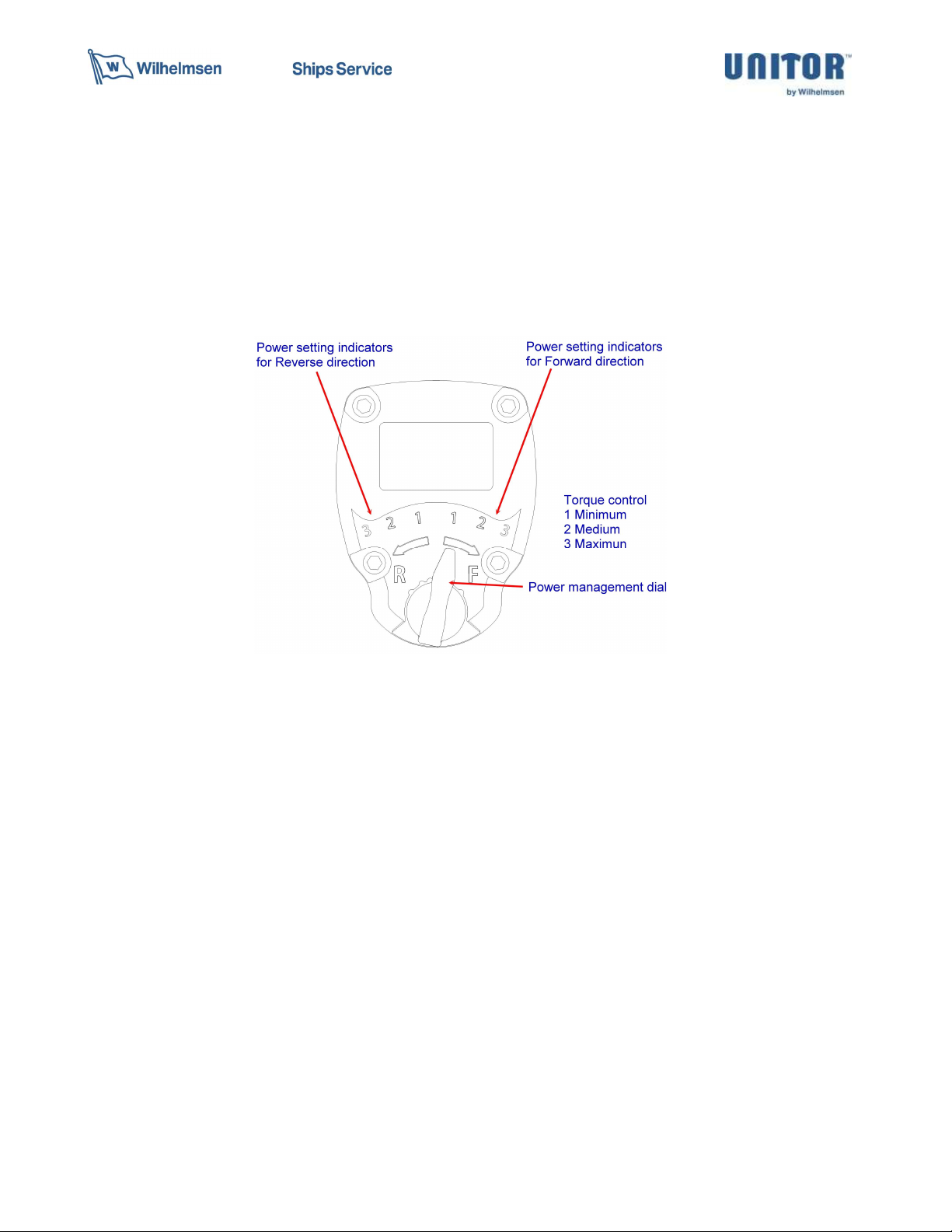

4.3.4 Simultaneously (at the same time), pull the trigger and pour a teaspoon of oil in the air inlet.

Then, push the forward and reverse button in both directions.

After an air tool has been lubricated, oil will discharge through the exhaust port during the

first few seconds of operation. Thus, the exhaust port must be covered with a towel before

applying air pressure. Failure to cover the exhaust port can result in serious injury.

4.3.5 Connect the impact wrench to the air supply and cover the exhaust port with a towel.

Run the impact wrench in both the forward and reverse directions for 20 to 30 seconds.

Oil will discharge from the exhaust port when air pressure is applied.

4.4 Impact Mechanism Lubrication

4.4.1 The impact wrench should be lubricated monthly.

Disconnect the impact wrench from the air supply before lubricating.

4.4.2 Disconnect the impact wrench from the air supply.

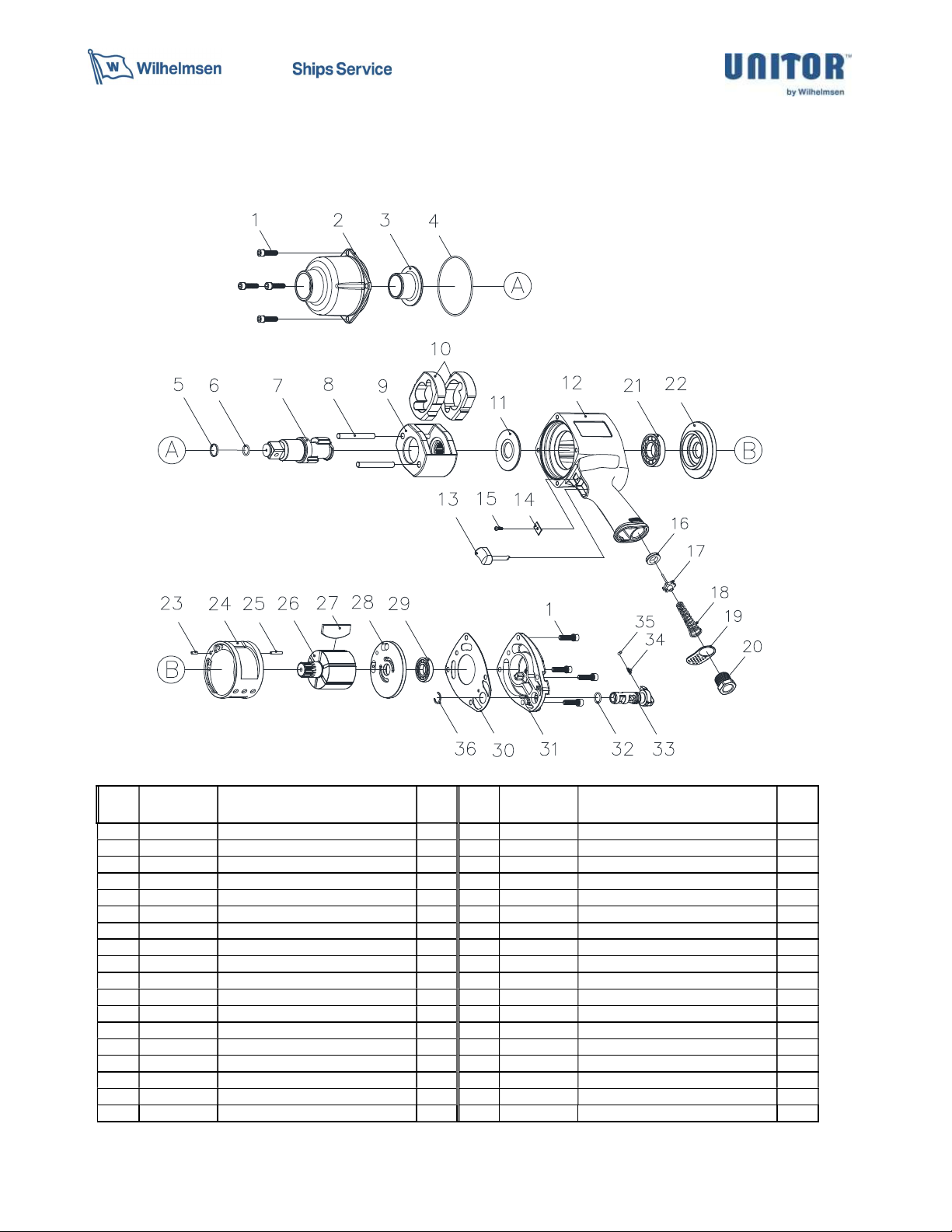

4.4.3 Remove the hexagon socket head screw from hammer housing.

4.4.4 Take off the hammer housing, put grease in the impact system.

4.4.5 Assemble the hammer housing, tighten the hexagon socket head screw.

4.4.6 Reconnect the air supply to the impact wrench and run for 20 to 30 seconds.