2

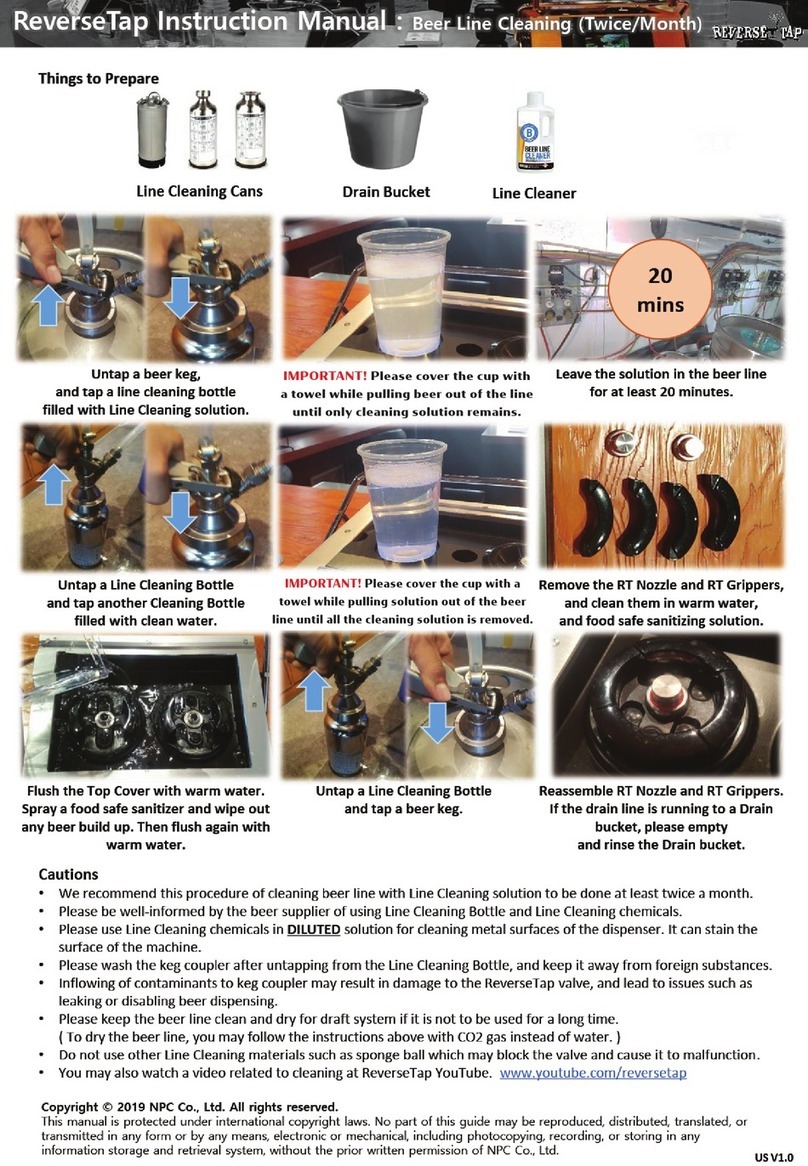

USER MANUAL

FERMENTING &

DISPENSING

The WilliamsWarn Kegerator can be

used to both ferment and dispense

fresh beer using WilliamsWarn

brewing technology.

FERMENTING

The WilliamsWarn Kegerator set range is

from -5 to 28 deg C but has no heating

element so will only operate at the higher

end of the ferment range if being used in

hot ambient temperatures. We recommend

using a WilliamsWarn BrewSnug™ for

ferment. https://williamswarn.co.nz/product/

brewkeg/brewsnug10/ if using our BrewKeg™

products. If you are using a WilliamsWarn

Brewsnug™ there is no need to use your

Kegerator for fermentation which gives you

the advantage of not waiting the 4-7 days

between finishing one brew and having the

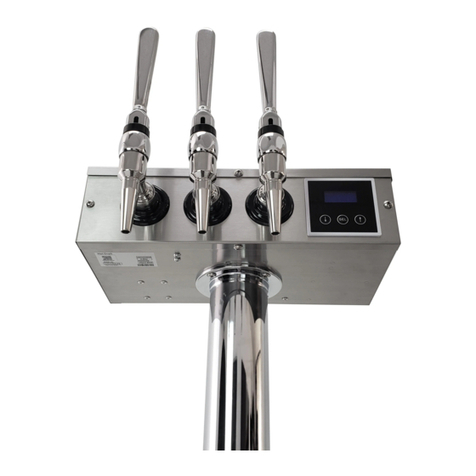

next ready to go. Once fermentation and

clarification is complete the brewer can then

easily attach the tap fittings to the top of the

Brewkeg™ lid and begin dispensing directly

from the Brewkeg™. See Figure 1 and 2 on

next page.

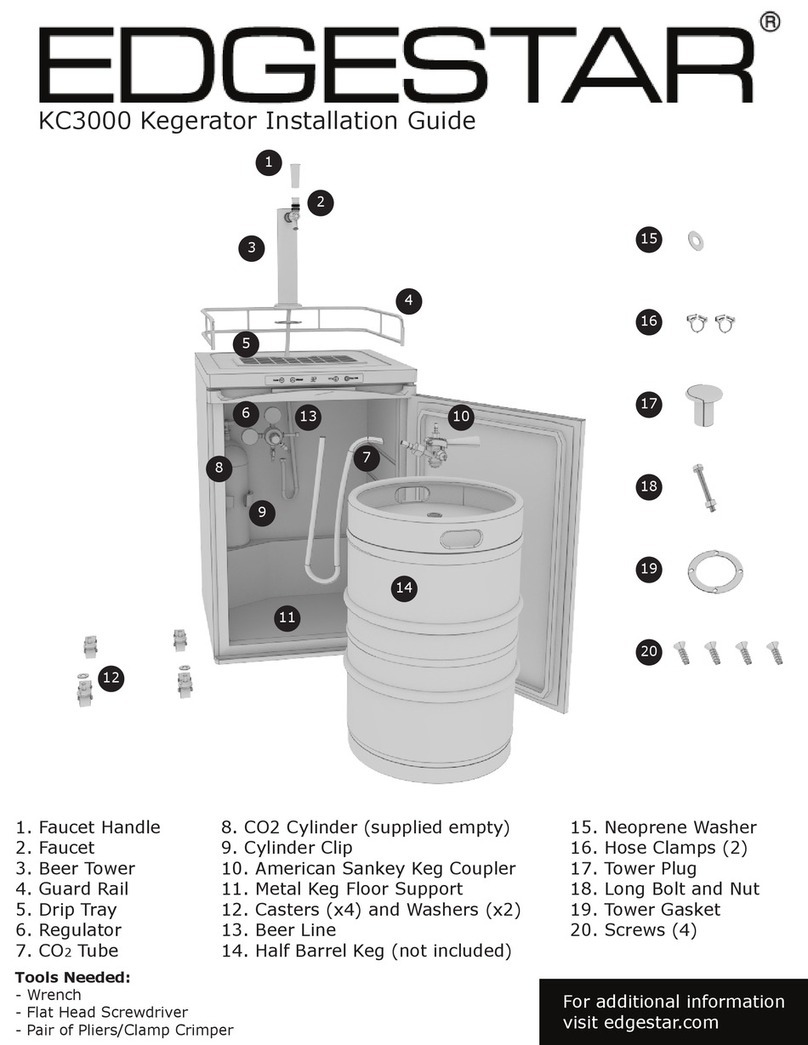

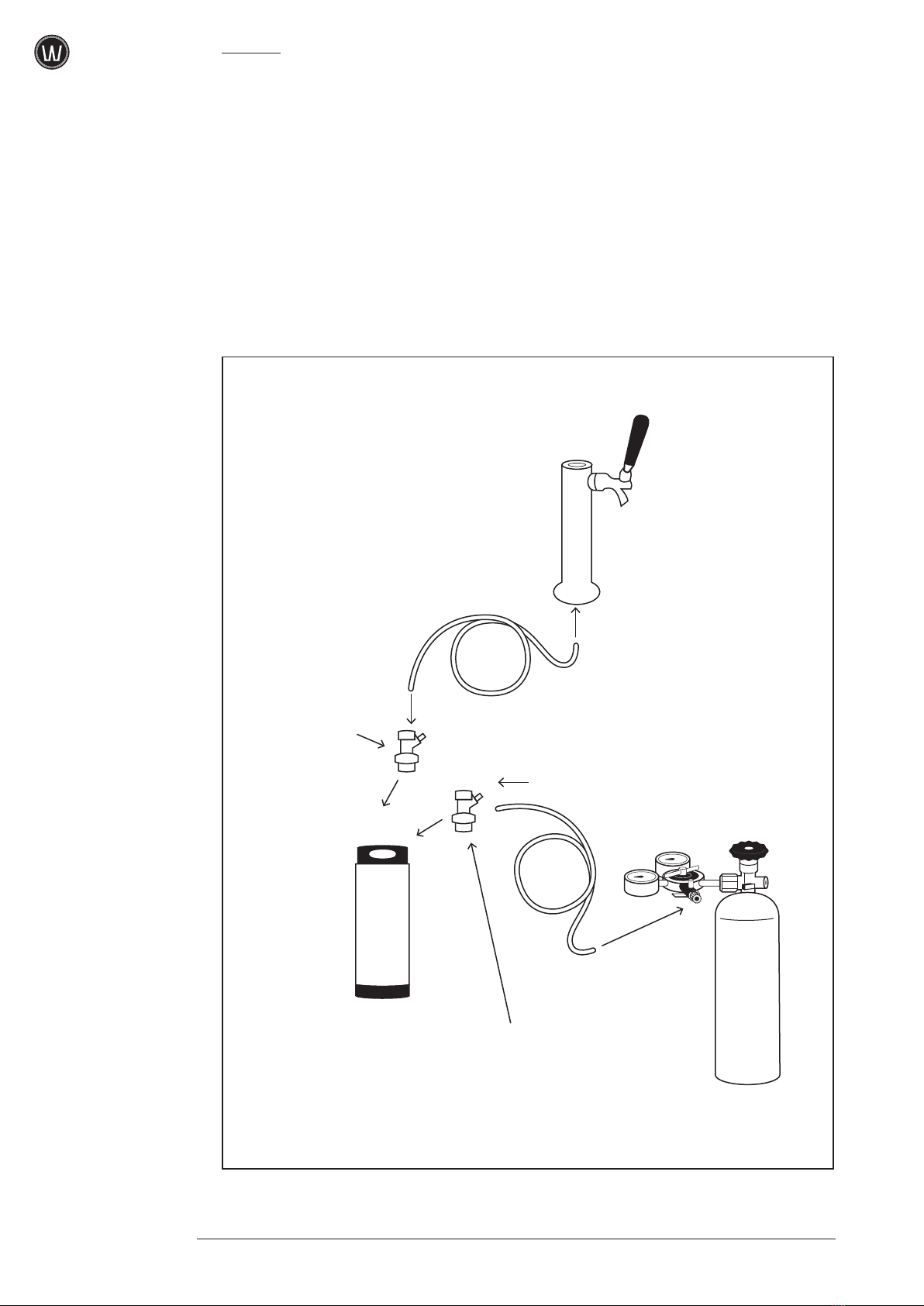

DISPENSING

The WilliamsWarn Kegerator can dispense a

variety of dispensing kegs once the brewing

process has been completed. There are two

styles of kegs that are used, the most common

for personal use is a Cornelius Keg. These

are available in 9.5L and 19L sizes (19L

shown in Figure 3 on next page). The other

style of keg which is commonly used in bars

and restaurants is a D-Sanke keg which is

available in 20L, 25L 30L and 50L sizes.

The D-Sanke keg will require a Coupler and

a Liquid and Gas Adaptor which allow you

to connect your kegerator beer and gas lines

(Figure 4 and 5 on next page). The extra parts

required to dispense from a D-Sanke keg can

be purchased at https://williamswarn.co.nz/

products/accessories/dispensing/.connections

as a Cornelius Keg.