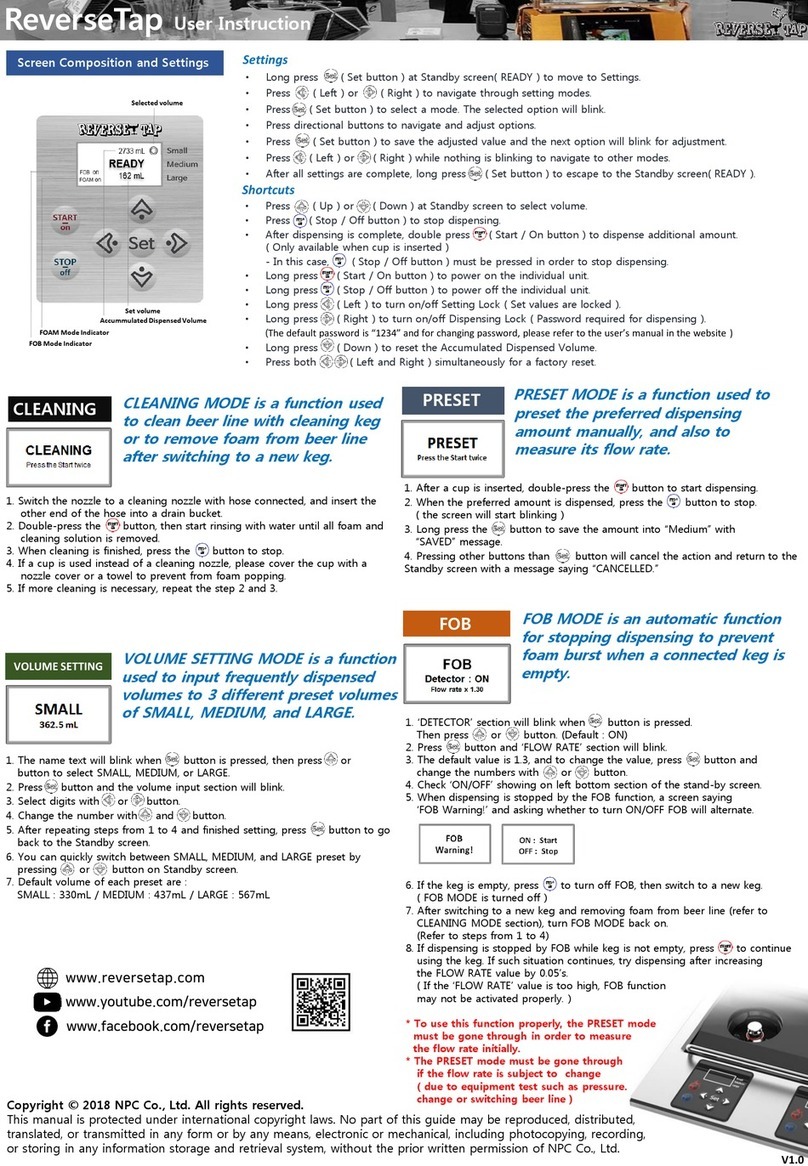

4

CLEAN

The cleaning process requires the BrewKeg50TM and all

parts to be: cleaned with cold water (removing all visible

brewing residues), washed with Brewery Detergent (removing

unseen build up), rinsed (removing all Brewery Detergent

residue), and sanitised with boiling water. Once this is done

you are ready to mix in your ingredients.

01. Boil 2L (0.5 gal.) of water, ready for use later.

02. Disassemble BrewKeg50TM into individual parts:

lid, silicon lid seal, Variable Pressure Relief Valve

(VPRV), beer tube, black anti-block fitting (on

end of plastic beer line) and all base components

of the bottom half of the sediment bottle.

03. In a sink, jug, or small bucket, add 1 teaspoon

(0.17 fl. oz.) of detergent per litre of hot tap water.

Soak all disassembled lid parts and sediment

bottle components in hot water, wiping clean with

the non-scratch sponge to remove any visible

yeast/krausen/hops residue of previous brew.

04. Rinse the entire BrewKeg50TM with cold water

over a drain or sink. Using the non-scratch

sponge remove the yeast ring, krausen and

hops residues at the BrewKeg50TM fill mark. Pay

special attention to the underside of the seal area

and bottom valve area. Turn the BrewKeg50TM

over and clean the underside of the bottom valve

and sediment bottle component. Ensure it is

thoroughly clean before closing the bottom valve

and pouring a small amount of boiling water

intothe underside of the closed bottom valve

fitting to sanitise.

05. Return to upright position and re-rinse with

cold water. Open the bottom valve to drain

excess water.

06. Re-assemble lid, beer tube, anti-block fitting,

and VPRV. Ensure the anti-block opening is

facing inward and beer tube is inserted firmly

into the lid beneath the correct port (Liquid

Portmarked ‘L’).

07. Turn the VPRV to fully closed position.

08. Install sediment bottle and fill BrewKeg50TM

with 3L (3 qt.) of hot water and add 2 teaspoons

(0.34 fl. oz.) of brewery detergent. Wipe interior

stainless-steel surfaces of BrewKeg50TM with

non-scratch sponge.

09. Fill jug again and boil 2L of water (0.5 gal.),

ready for use later.

10. Install lid with silicon seal properly. The small

tabs on the silicon seal should line up with the

seams down the long length of the lid. Shake

vessel upright, inverted, and on its side for at

least 10 seconds.

11. After every 4-5 uses of the BrewKeg50TM it

is a good idea to run the Brewery Detergent

through your Beer taps. Attach draft beer taps

and flush beer line and beer out port with the

hot detergent.

NOTE: Enough pressure should build up via shaking

of boiling water in the BrewKeg50TM to allow flushing of

the beer line. If there is not enough pressure, attach

CO2 gas cylinder Gas-Disconnect (Grey) to the gas port

(marked with a ‘G’ on the lid) and pressurise slightly to

0.3 bar (5 psi). The correct methods for connecting and

disconnecting your gas and liquid disconnects to your

BrewKeg50TM lid can be found in the Video Resources

on the WilliamsWarn website.

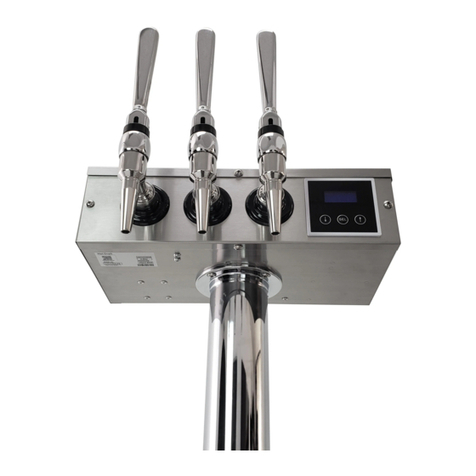

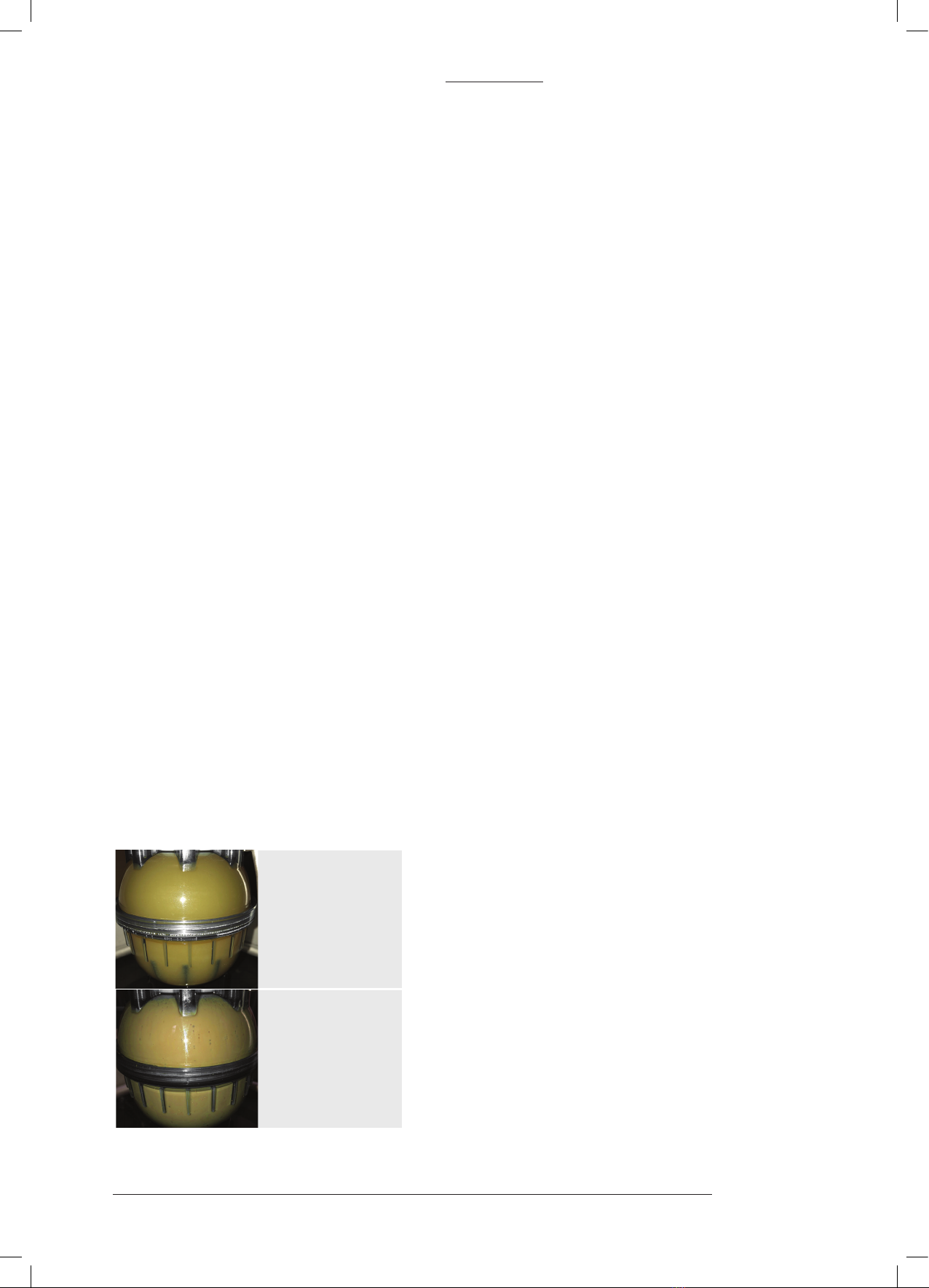

Fig 1: Disassembled BrewKegTM Lid