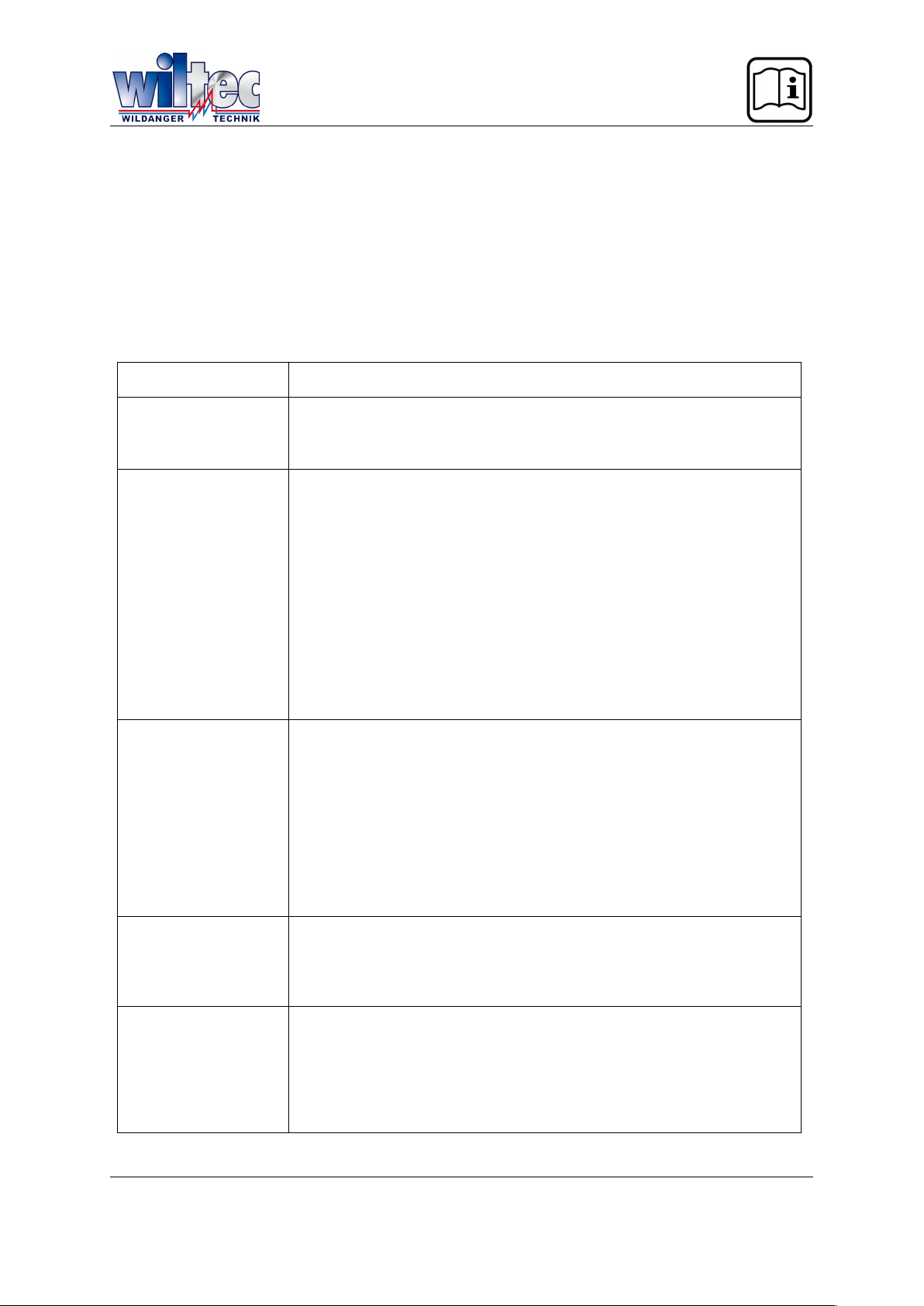

TROUBLESHOOTING

1. Maintenance or repairs performed by technical assistance centers not authorized by the manufac-

turer will immediately render null and void the manufacturer warranty.

2. If user want to operate machine as following, the operator must specialist in field of electrify and

safety.

3. If you have any questions about the suggested solutions or are unable to complete them, please

contact the manufacturer or an authorized service partner immediately.

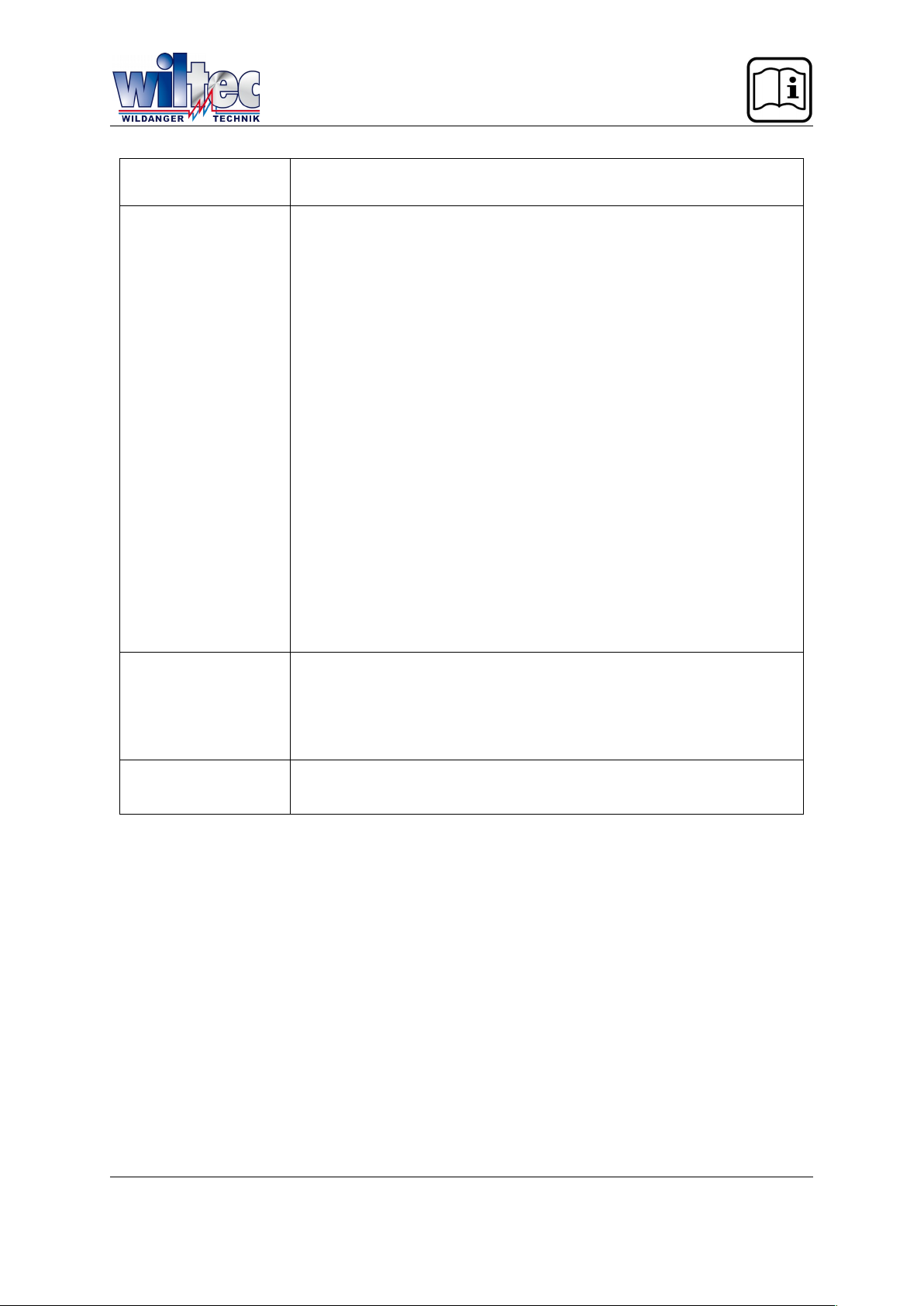

TIG180, TIG200

Faults Solutions

1.Power indicator is

not lit, fan does not

work/no welding out-

put

1. Power switch is out of work.

2. Check if electrify wire net (which is connected to input cable) is in

work.

3. Check if input cable is out of circuit.

2.Power indicator is

lit, fan does not work

or revolve several cir-

cles/no welding output

1. Maybe you connected wrong to 380v power so that the machine is

in protection circuit. Connect to 220v power and operate machine

again.

2. 220v power is not stable (input cable is too slender) or input cable is

connected to electrify wire net which causes that the machine is in

protection circuit. Add the section of cable and tighten input connec-

tor firmly. Close machine 2-3 minutes then switch it on again.

3. Cable is loose from switch to power panel; tighten them again.

4. Switch the machine on and off several times because it is in protec-

tion circuit. Shut down the machine 2-3 minutes and then switch it

on again.

5. Main circuit 24v relay of the power panel is not closed or has dam-

aged. Check 24v power source and relay. If relay has been dam-

aged replace it with same model.

3. Fan is working,

indicator is not lit and

sound of HF arc-strik-

ing cannot be heard/

wiping welding cannot

strike arc.

1. Positive and negative electrodes of VH-07 insert component voltage

should be about DC308v from power panel to MOS board.

(1) If circuit is broken and silicon bridge has poor contact.

(2) If some of four high electrolytic (about 470UF/450V) of power

panel capacitor are leaking.

2. There is a green indicator in auxiliary power of MOS board ,if it is not

on, auxiliary power is out of work .Check fault spot and connect with

seller.

3. Check if connectors have poor contact.

4. Check control circuit and find out reasons or connect with seller.

5. Check if control cable of torch is broken.

4. Abnormal indicator

is not on, sound of HF

arc-striking can be

heard, but there is no

welding output.

1. Check if torch cable is broken.

2. Check if grounding cable is broken or not connected to welding

piece.

3. Output terminal of positive electrode or torch electrify is loosened

from inter-machine.

5. Abnormal indicator

is not lit, sound of HF

arc-striking cannot be

heard, wiping welding

can strike arc.

Primary cable of arc-striking transformer is not connected to power

panel firmly; tighten it again.

Arc-striking tip is oxidized or too far away; give a good polish to it or

change if there is about 1 mm between arc-striking tip.

Switch (sticking/argon-arc welding) is damaged, replace it.

Some of HF arc-striking circuit components are damaged; find out

and replace them.

© by WilTec Wildanger Technik G bH Seite 19

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de