WARPP INTIG-200IDS User manual

Other WARPP Welding System manuals

WARPP

WARPP INTIG-315 AC/DC User manual

WARPP

WARPP DCWF-V1 User manual

WARPP

WARPP INMIG 250 IH User manual

WARPP

WARPP WS-200 User manual

WARPP

WARPP INARC 200 IDS User manual

WARPP

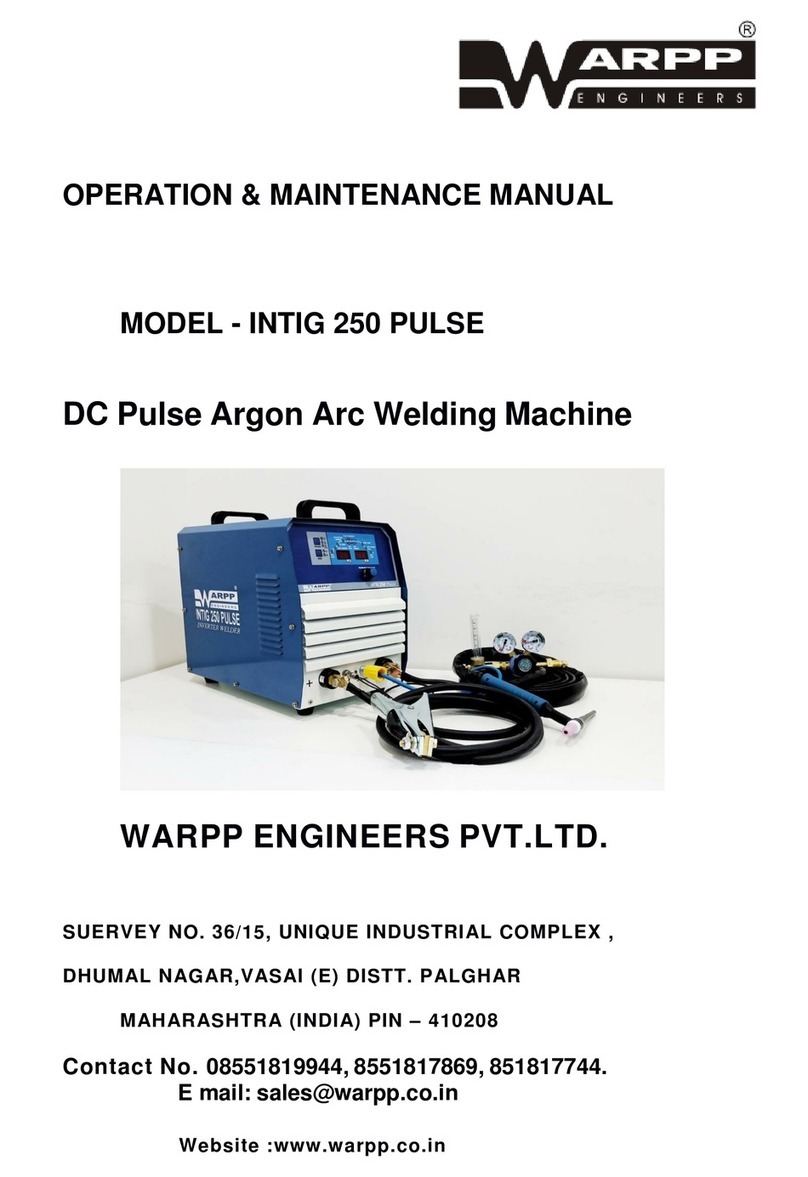

WARPP INTIG 250 PULSE Manual

WARPP

WARPP IN ARC-I series User manual

WARPP

WARPP WTR-600 User manual

WARPP

WARPP AIRCUT 100I User manual

WARPP

WARPP INTIG 402 PULSE User manual

WARPP

WARPP INTIG-PULSE series User manual

WARPP

WARPP LGK-40 User manual

WARPP

WARPP INTIG 316 AC/DC User manual

WARPP

WARPP INARC-400 I User manual

WARPP

WARPP INARC IH SERIES User manual

WARPP

WARPP INTIG 401 User manual

WARPP

WARPP INTIG 402 PULSE User manual

WARPP

WARPP WARMIG-400 User manual

WARPP

WARPP WTR-400 User manual

WARPP

WARPP INTIG 250 User manual

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual