4

Installation

These instructions should be followed at all times. Failure to follow

these instructions could result in injury to yourself and others.

TO REDUCE RISK OF INJURY OR DAMAGE TO THE UNIT:

Read this manual thoroughly before installation and operation. DO NOT

proceed with installation and operation if you have any questions or do

not understand anything in this manual. Contact your representative or

the manufacturer rst.

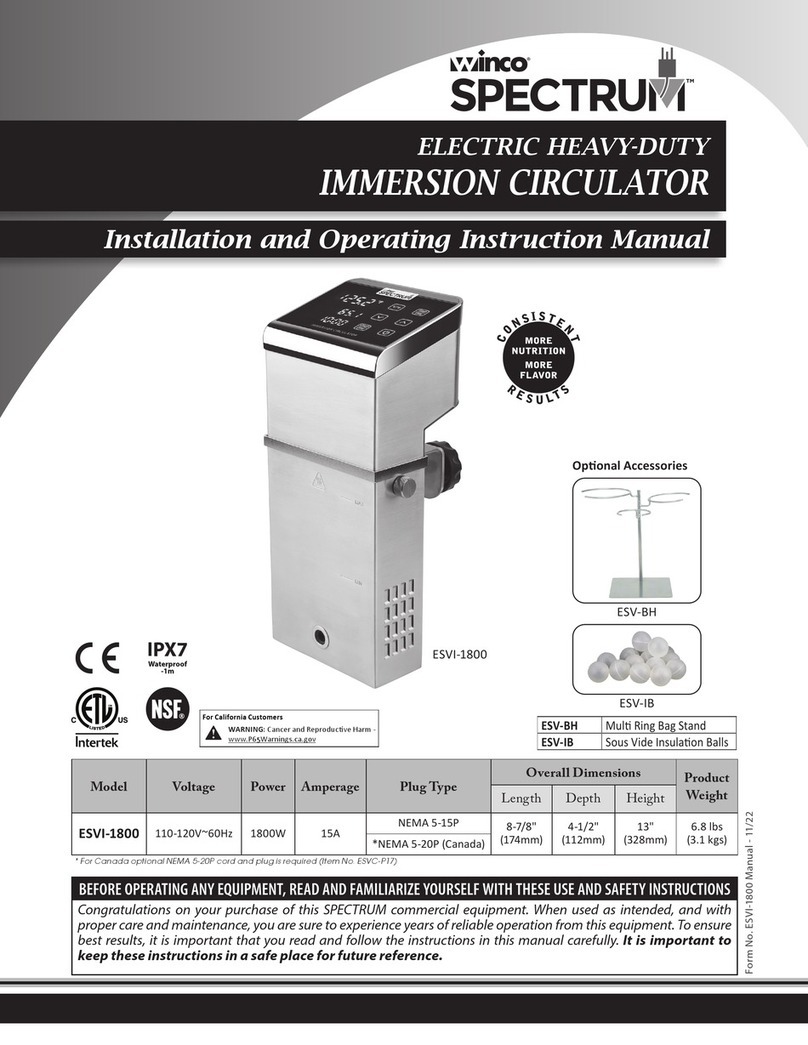

1. Remove the SPECTRUM™ Commercial Immersion Circulator from

packaging. Be certain that all protectives plastics and residues are

thoroughly cleaned from its surfaces.

2. Select water bath container (not included) that is rated for

temperatures of 212°F(100°C), and will hold the maximum

suggested water volume of 7.9 gal(30L) with a minimum

water depth of 4-5/16”(110mm) and maximum water depth of

6-1/2”(165mm) after food product displacement.

3. Place water bath container on a rm level surface.

4. Hold the Clamp Hook tightly, push the Slide Plate with your thumb

and slide the Connection Sleeve to the desired position, remove

thumb from Slide Plate, the connection sleeve should be tight on

the Housing.

5. Hang the Immersion Circulator into water bath container and

tighten the Clamp Handle to secure in place.

6. Add suggested water volume of 7.9 gal(30L) into the water bath.

Do not position or operate near combustible materials/ammable

objects.

Ne pas placer ni faire fonctionner l'appareil près de

matériels combustibles ou d'objets inflammables.

CAUTION

ATTENTION

Fire Hazard.

Correct installation precautions,

procedures and regulations

must be followed. Operation

and safety training is necessary

for all users of this equipment.

Risque d'incendie

La surchaue des vapeurs d'huile ou de

l'huile peut s'enammer et provoquer

un incendie. Surveillez la température,

la qualité et le niveau d’huile. Utilisez et

entretenez le système d'élimination des

vapeurs d'huile.

The equipment must be

installed by qualied personnel

only. Correct installation

precautions, procedures and

regulations must be followed

in order to reduce the risk of

re. Hood and re suppression

systems must be maintained

per manufacturer's guidelines.

Only qualied and trained

personnel are to use this

equipment.

Faire chauer l'huile avec précaution. Si

l'huile fume, réduire le feu. Ne pas laisser

l'appareil sans surveillance. Si le feu se

produit, éteindre l'appareil, couvrir jusqu'à

refroidissement. Ne pas mettre l'eau dans

l'huile chaude ou enammée. Ne faites pas

fonctionner avec de l'huile sous la barre

d'huile. L’huile sale a un point d'éclair

plus bas. Remplacer l'huile sur une base

régulière. Maintenir le niveau d'huile

correct. Utiliser un système d'évacuation

de la vapeur d'huile (capot) pour réduire

l'accumulation de graisse et d'huile sur les

surfaces de paroi ou de plafond.

WARNING AVERTISSEMENT

Proper Grounding · Mise à la terre correcte

This machine is provided with a three-pronged

grounding plug. The outlet to which this plug

is connected must be properly grounded. If the

receptacle is not the proper grounding type, contact an

electrician. DO NOT, under any circumstances, cut

or remove the third ground prong from the power cord

or use any adapter plug.

Cette machine est équipée d'une che à trois broches.

La prise sur laquelle cette che est branchée doit être

correctement mise à la terre. Si la prise n'est pas le type de

mise à la terre, contactez avec un électricien. NE PAS, en

aucun cas couper ou enlever la troisième broche de terre à

partir du cordon d'alimentation ou utiliser un adaptateur.

USE A GROUNDED OUTLET

DO NOT ADD AN ADAPTOR

TO THE PLUG

UTILISER UNE PRISE AVEC MISE

À LA TERRE NE PAS AJOUTER UN

ADAPTATEUR SUR LA FICHE

Electrical Shock Hazard

Keep water and other liquids

from entering the inside of the

unit. Liquid inside the unit could

cause an electrical shock.

Risque de choc électrique

Conserver l'eau et d'autres liquides

de pénétrer à l'intérieur de l'appareil.

Liquide à l'intérieur de l'appareil pourrait

provoquer un choc électrique.

Do not spray water or cleaning

products. Liquid could contact

the electrical components

and cause a short circuit or an

electrical shock. Do not use unit

if power cord is damaged or has

been modied.

Ne pas pulvériser de l'eau ou des produits

de nettoyage. Le liquide pourrait contacter

avec les composants électriques et causer

un court-circuit ou un choc électrique.

Ne pas utiliser l'appareil si le cordon

d'alimentation est endommagé.

ou a été modié.

WARNING AVERTISSEMENT

7. Proper connections and power supply are essential for ecient

performance. Supply the appropriate power and connect to source;

your Immersion Circulator is now ready to turn on and operate.

(For power supply please see technical specication on page 1).

Fournir l'alimentation secteur appropriée et brancher l’appareil à la

source d'alimentation ; votre Circulateur d'immersion est maintenant

8. The units are wired to be used with a standard 110V/AC receptacle

and may be plugged into any convenient outlet.

9. The installation of the unit must conform to the NATIONAL

ELECTRIC CODE, ALL LOCAL ELECTRIC CODES AND ORDINANCES, AND

ALL THE LOCAL ELECTRICAL COMPANY RULES AND REGULATIONS.

Additionally, we recommend a 4" spacing surrounding the unit in

order to provide adequate ventilation.