P/N 11485.00 Rev A Page 7 of 8

IMPORTANT: All connections must be wrench-tightened. Do

not make connections to the gas regulator too tight. Making the

connections too tight may crack the regulator and cause a gas

leak. Do not allow the regulator to turn on the pipe when

tightening fittings.

Use only pipe-joint compound made for use with Natural and LP

gas.

Do not use TEFLON®† tape. You will need to determine the fittings

required depending on your installation.

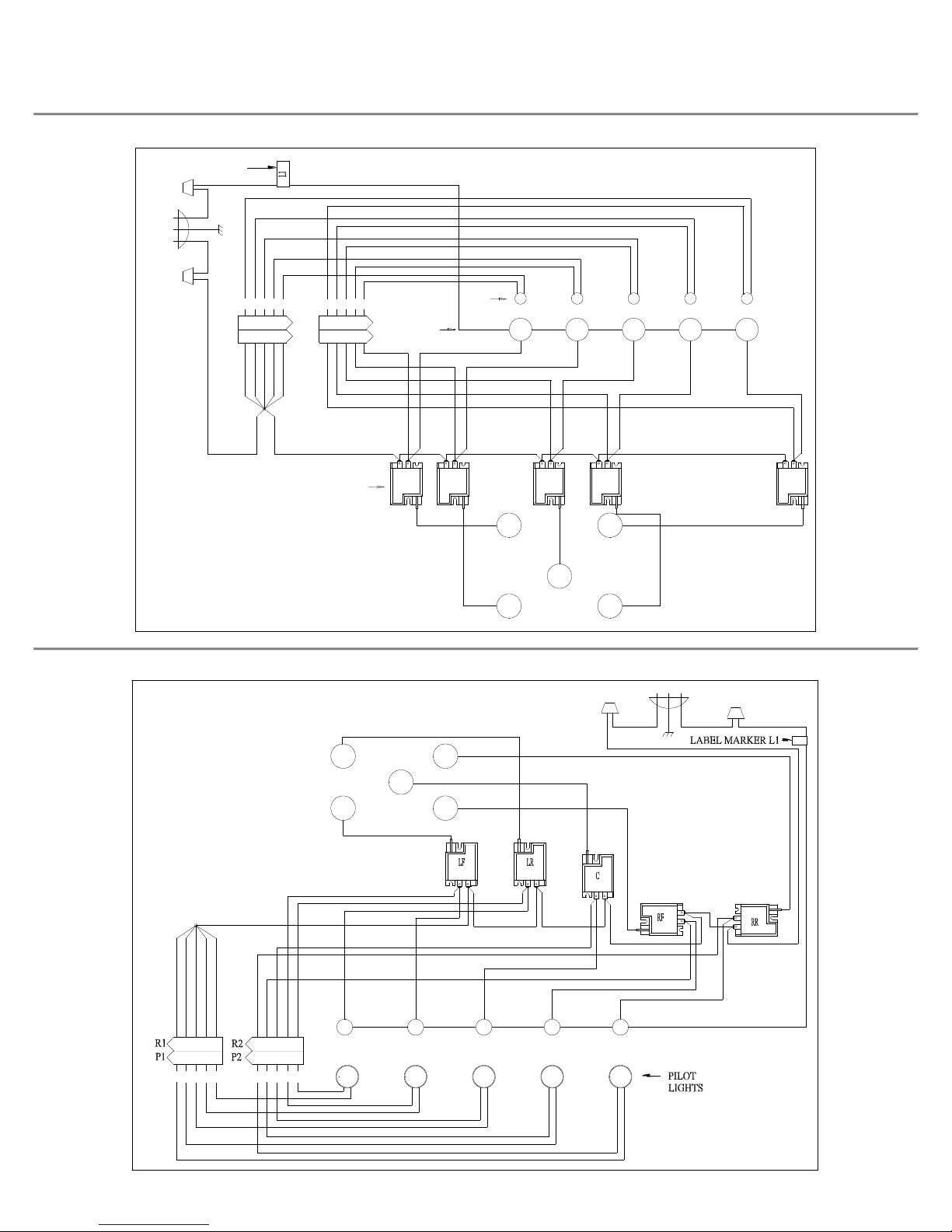

Typical flexible connection

1. Apply pipe-joint compound made for use with LP gas to the

larger thread ends of the flexible connector adapters (see B

and F in the following illustration).

2. Attach 1 adapter to the gas pressure regulator and the other

adapter to the gas shutoff valve. Tighten both adapters.

3. Use a 15/16" combination wrench and channel lock pliers to

attach the flexible connector to the adapters. Check that

connector is not kinked.

Complete Connection

1. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

2. Test all connections by brushing on an approved noncorrosive

leak-detection solution. If bubbles appear, a leak is indicated.

Correct any leak found.

3. Remove surface burner caps and burner heads and grates

from parts package. Place burner cap and burner head.

Burner caps and burner heads should be level when properly

positioned. If burner caps and burner heads are not properly

positioned, surface burners may not light and continuous

sparking may occur. Place burner grates over burners and

caps.

A. Burner cap (Domed)* G. Burner Cap (Flat)

B. Gas Tube Opening H. Gas Tube Opening

C. Burner Head* I. Burner Head

D. Electrode Notch J. Electrode Hole

E. Electrode K. Burner Bracket

F. Burner Base L. Electrode

Dual Burner Single Burner

*Same for all Dual Burners

See Product Dimension Section for Burner Locations

Caution: Improper positioning of burner can damage cooktop and cause

injury to persons.

Correct positioning results in even flame distribution and

appearance.

DO NOT INSTALL Dual Burner Heads on Single Burner Base

Or Single Burner on Dual Base.

Complete Installation

Electronic Ignition System

Check Operation of Surface Burners

1. Push down and turn the surface burner control knobs to the

“HI” position.

The surface burner flame should light within 4 seconds. The

first time a surface burner is used it may take longer than 4

seconds to light because of air in the gas line.

2. Check the flame on “HI” for a blue color. It should be clean

and soft in character. No yellow tip, blowing or lifting of flame

should occur. NOTE: LP Gas can result in a small yellow

tip on Flame. This is normal. Occasional orange flashes are

normal and reflect different elements in the air or gas.

3. Repeat at “LO” position.

4. Repeat at Ultra-Low Position.

5. After verifying the proper burner operation, turn the control

knobs to “OFF.”

6. Check that operating lights are working.

If burners do not light properly:

Turn surface burner control knob to the “OFF” position.

Check that the power supply cord is plugged in and the circuit

breaker has not tripped or the fuse blown.

Check that the gas shutoff valves are set to the “open”

position.

Check that burner heads and caps are properly positioned on

burner bases.

Recheck operation of surface burners. If a burner does not light at

this point, contact your dealer or customer service 1-877-387-6721

for assistance.

OFF HIGH HEAT MED HEAT

LOW HEAT LOW HEAT

ULTRA

Control Knob Setting

Dual

Burner

Only

A. Gas pressure regulator

B. Use pipe-joint compound

C. Adapter - Must have 1/2"

male pipe thread

D. 5/8" min. flexible connector

E. Adapter - Must have 1/2" male

pipe thread

F. Use pipe-joint compound.

G.1/2" or 3/4" gas pipe

H.Manual gas shutoff valve