2

1Safety information........................................................................................................................................................3

1.1 Safety................................................................................................................................................................ 3

1.2 230V AC............................................................................................................................................................ 3

1.3 Back-up batteries .............................................................................................................................................. 3

1.4 Application......................................................................................................................................................... 3

1.5 Cable routing and electrical connection............................................................................................................. 3

2Structure of the smoke panel......................................................................................................................................4

3

Max numbers of actuators per motor line and panel

....................................................................................................4

4Accessories and spare parts ......................................................................................................................................5

5Technical data..............................................................................................................................................................6

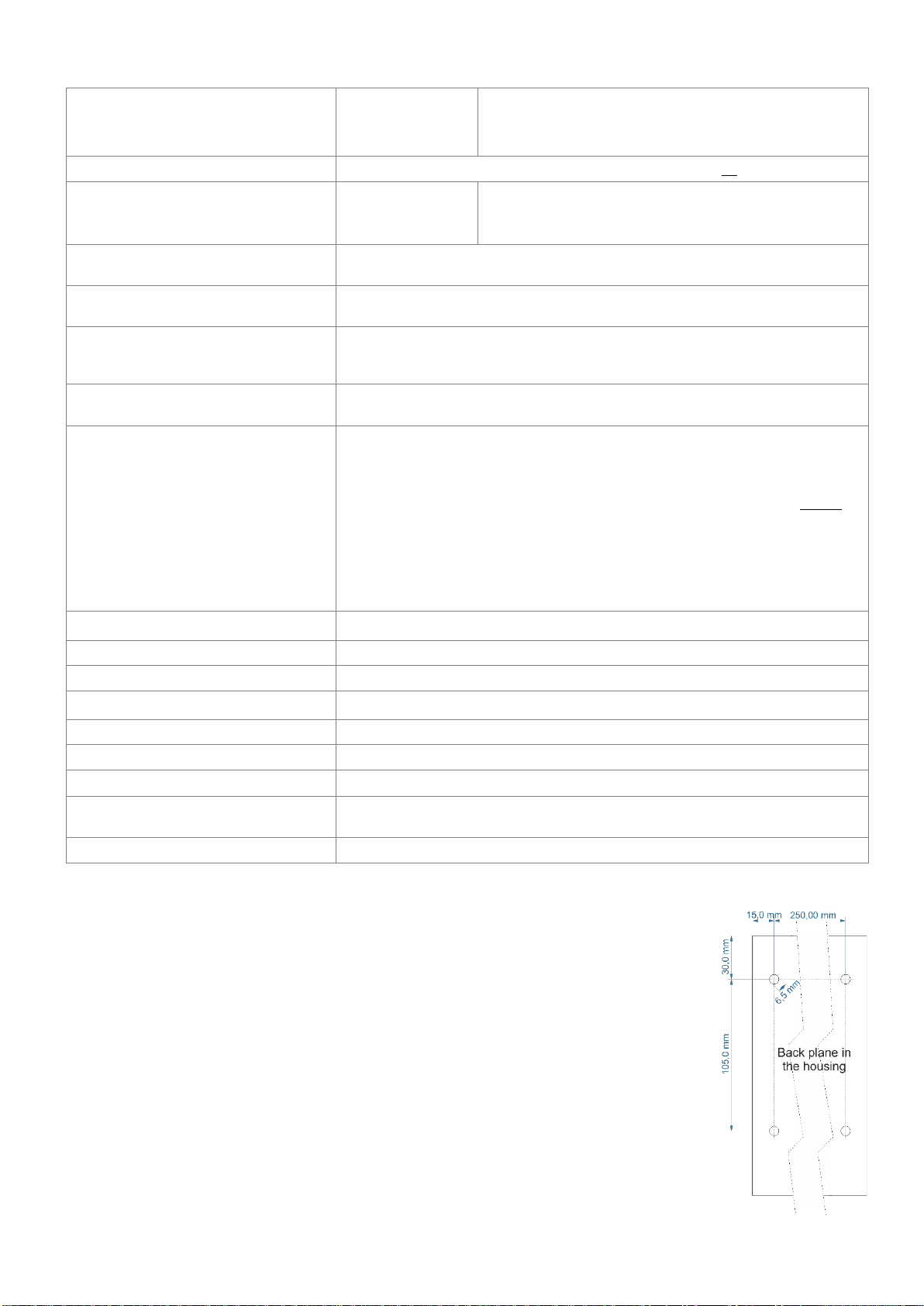

6Mounting.......................................................................................................................................................................7

7Installation....................................................................................................................................................................8

7.1 Cable routing..................................................................................................................................................... 8

7.2 Cables into housing........................................................................................................................................... 8

7.3 Connection of safety earth wire and 230V AC................................................................................................... 8

7.4 Installation of the break glass unit, ventilation keypad and smoke detector...................................................... 8

7.5 Assembly instructions........................................................................................................................................ 8

8Cable dimensioning.....................................................................................................................................................9

8.1 Maintaining the cable functions......................................................................................................................... 9

8.2 Max. cable Length............................................................................................................................................. 9

8.2.1 Formula for the calculation of the maximum actuator cable length ...............................................................9

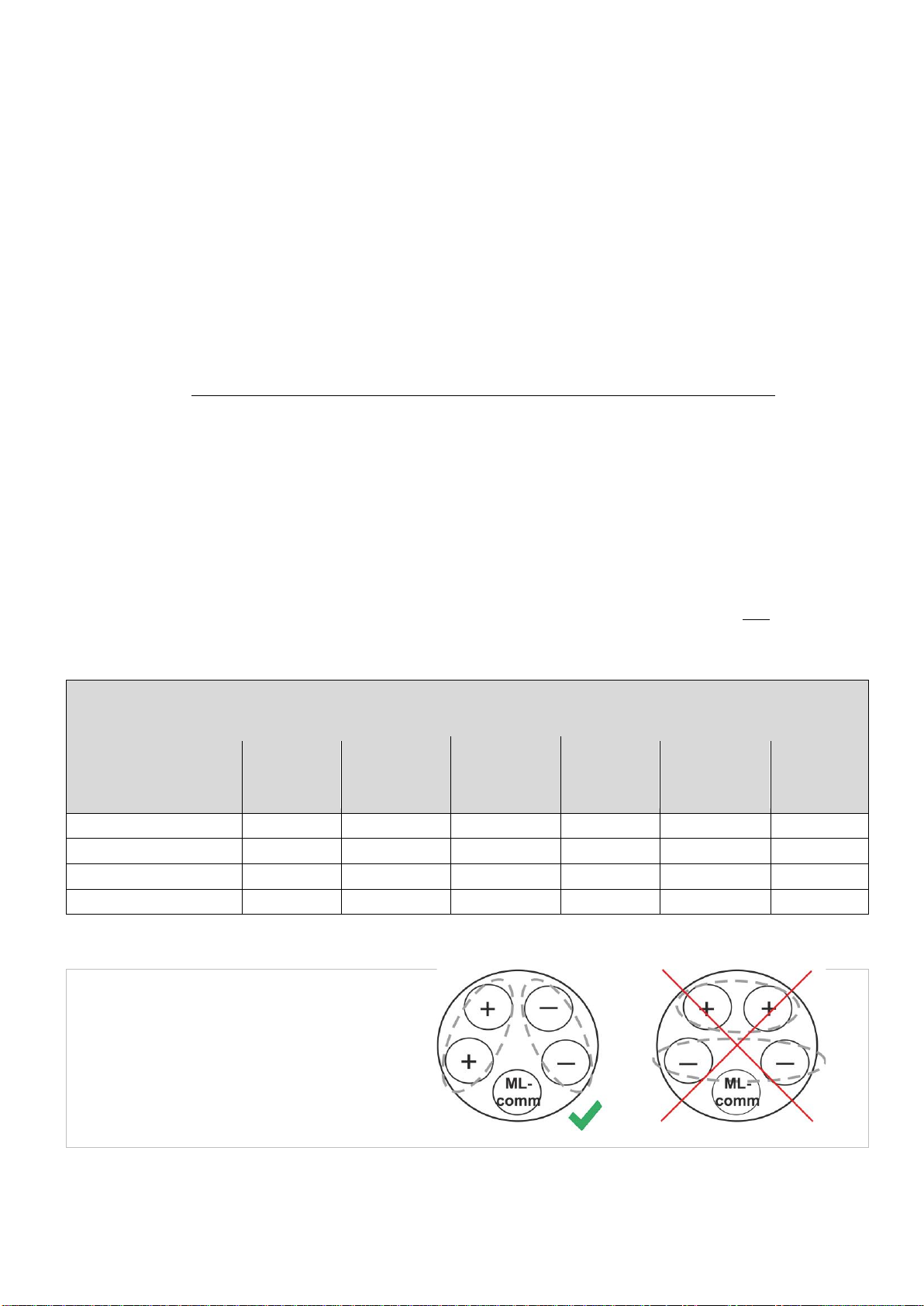

8.2.2 Max cable length –±24V standard actuators ................................................................................................9

8.2.3 Max cable length –actuators with MotorLink®...............................................................................................9

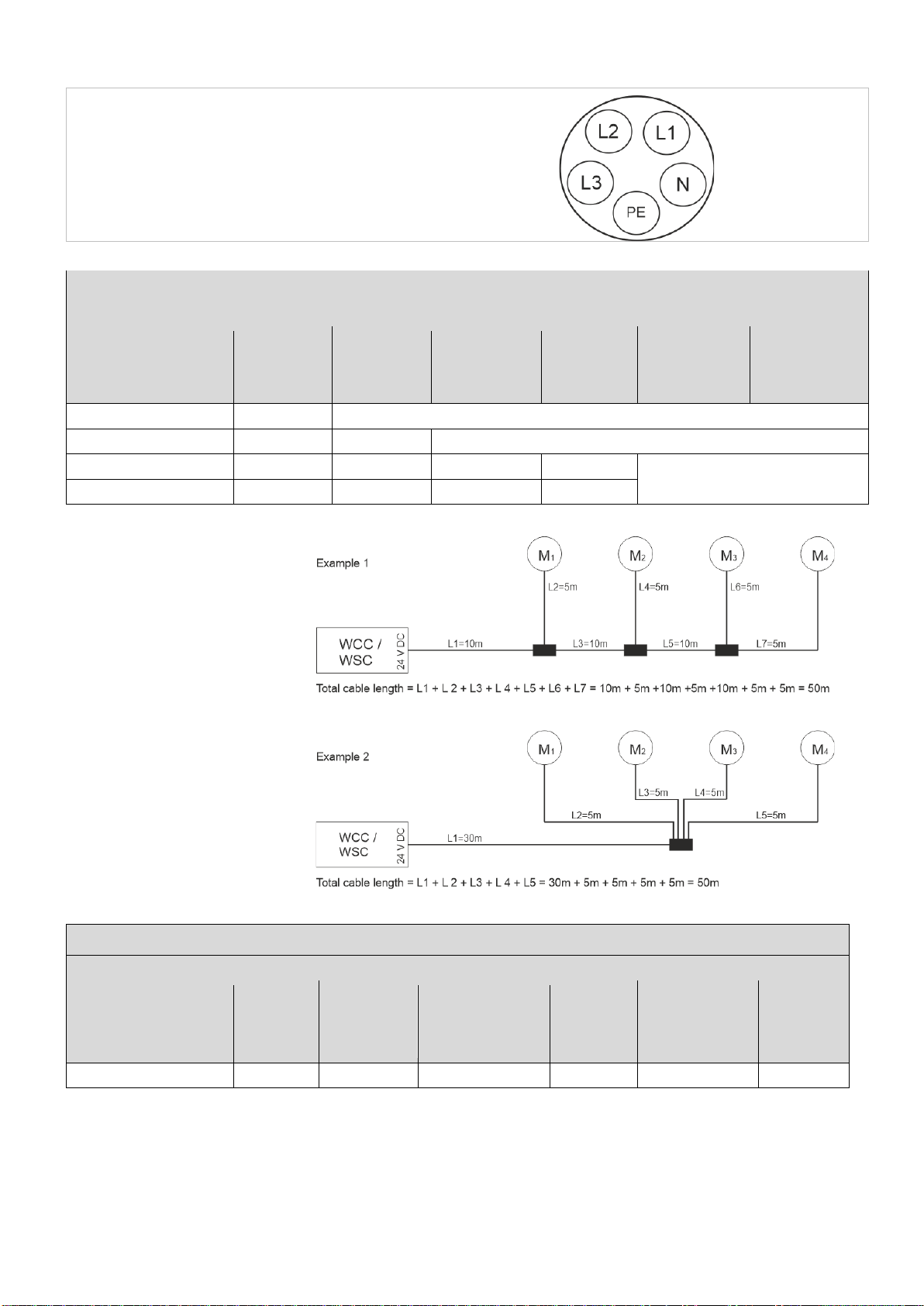

8.2.4 Max cable length –Pyrotechnic gas generator ...........................................................................................10

9Cable plan for connection to WSC 104 ....................................................................................................................11

10 Description of card and mains connection..............................................................................................................11

10.1 Mains connection and power supply (WCA 1P1) .............................................................................................11

10.2 Main card WSA 1SS.........................................................................................................................................12

11 DIP switch configuration...........................................................................................................................................18

12 Back-up batteries.......................................................................................................................................................19

13 Configuration of panel...............................................................................................................................................19

13.1.1 Motor line ....................................................................................................................................................19

13.1.2 Smoke zone ................................................................................................................................................19

13.1.3 Local input...................................................................................................................................................19

13.1.4 Local output.................................................................................................................................................20

14 Fault detection via LED..............................................................................................................................................20

14.1 Fault detection on the smoke panel..................................................................................................................20

14.2 Fault indication on break glass unit..................................................................................................................21

15 Hardware error ...........................................................................................................................................................21

15.1 Error on the Power supply................................................................................................................................21

15.1.1 Blown fuses –6.3A slow .............................................................................................................................22

16 Commissioning and test run.....................................................................................................................................22

16.1 The control ventilation panel is completely installed, without the operating voltage applied.............................22

16.2 With mains voltage, without accumulator.........................................................................................................22

16.3 With mains voltage, with accumulator..............................................................................................................22

16.4 Ventilation keypad............................................................................................................................................22

16.5 Break glass unit WSK 50x................................................................................................................................22

16.6 Smoke detectors ..............................................................................................................................................23

16.7 Emergency power supply test..........................................................................................................................23

16.8 Wind/rain detector............................................................................................................................................23

17 Maintenance ...............................................................................................................................................................23

17.1 Maintenance agreements.................................................................................................................................23

17.2 Replacement 1SS card ....................................................................................................................................24

18 Declaration of Conformity and Declaration of Performance ..................................................................................24