2

1. EN ........................................................................................................................................3

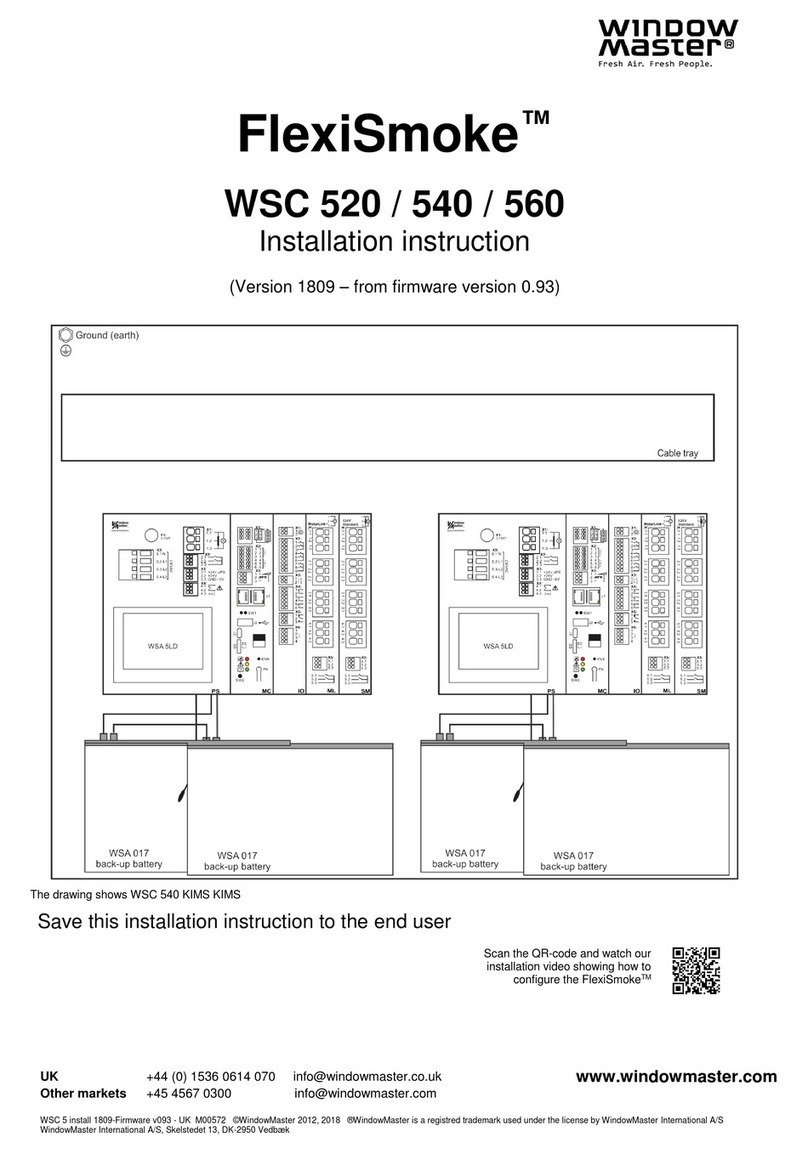

System overview...........................................................................................................................................................3

Generel information.......................................................................................................................................................3

Electrical installation......................................................................................................................................................4

Cable entries in the unit............................................................................................................................................4

The connections of the FutureVent™ unit.................................................................................................................4

Service point .................................................................................................................................................................4

FutureVent™ bus connection....................................................................................................................................4

230V supply..............................................................................................................................................................5

Service gateway (used by WindowMaster®service engineers).....................................................................................5

Checking the electrical installation ................................................................................................................................5

Checking the functionality of the installation when commissioned............................................................................5

Troubleshooting on the FutureVent™ installation .....................................................................................................6

2. DK........................................................................................................................................6

System oversigt.............................................................................................................................................................6

Generelle informationer.................................................................................................................................................6

Elektrisk installation.......................................................................................................................................................7

Kabelindføringer i enheden.......................................................................................................................................7

FutureVent™ enhedens tilslutninger.........................................................................................................................7

Servicepunkt .................................................................................................................................................................7

FutureVent-bus forbindelse.......................................................................................................................................8

230V forsyning..........................................................................................................................................................8

Service gateway (anvendes af WindowMaster®serviceteknikere)................................................................................8

Kontrol af elektrisk installation.......................................................................................................................................9

Kontrol af funktion når anlægges sættes i drift..........................................................................................................9

Fejlfinding på FutureVent™ anlæg ...........................................................................................................................9