INSTALLATION AND USER MANUAL WINESP40CAPRO

Page 3

User manual

Table of contents

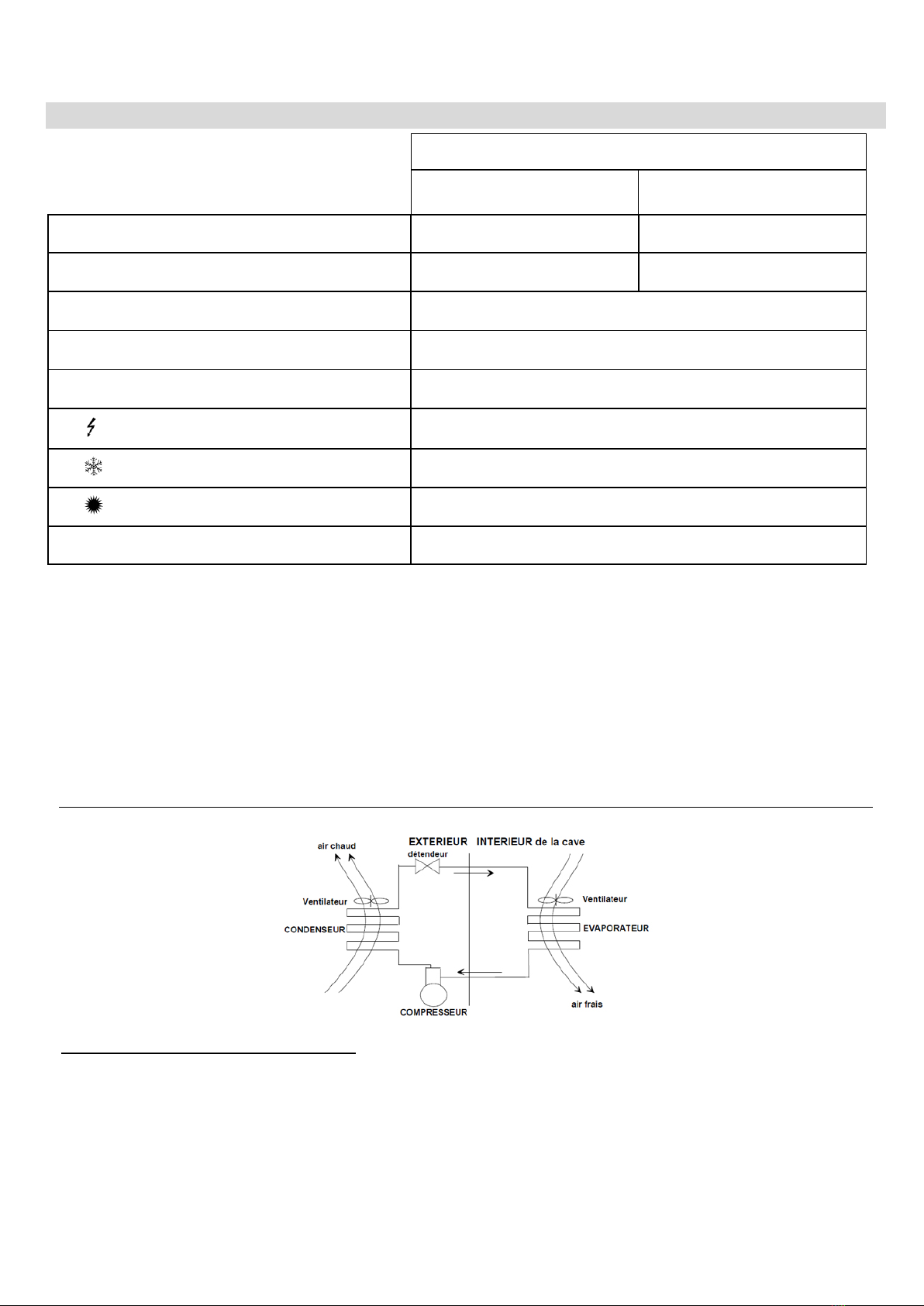

1.TECHNICAL DATAS ....................................................................................5

2.EQUIPMENT...............................................................................................7

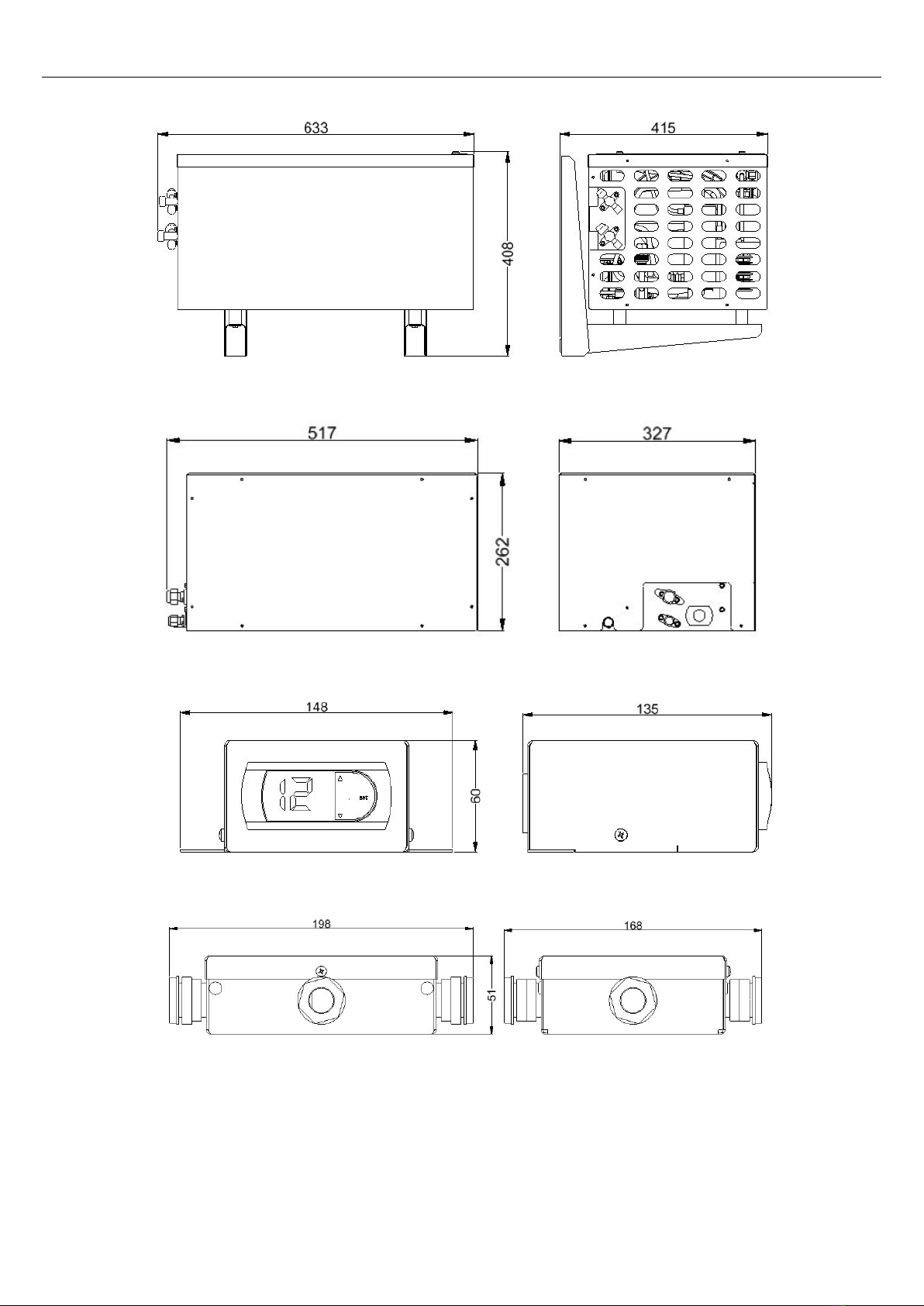

2.1.Outside unit .............................................................................................. 7

2.2.Inside unit ................................................................................................ 7

2.3.Thermostat ............................................................................................... 7

2.4.Connection box ......................................................................................... 7

2.5.Connection drawing ................................................................................... 7

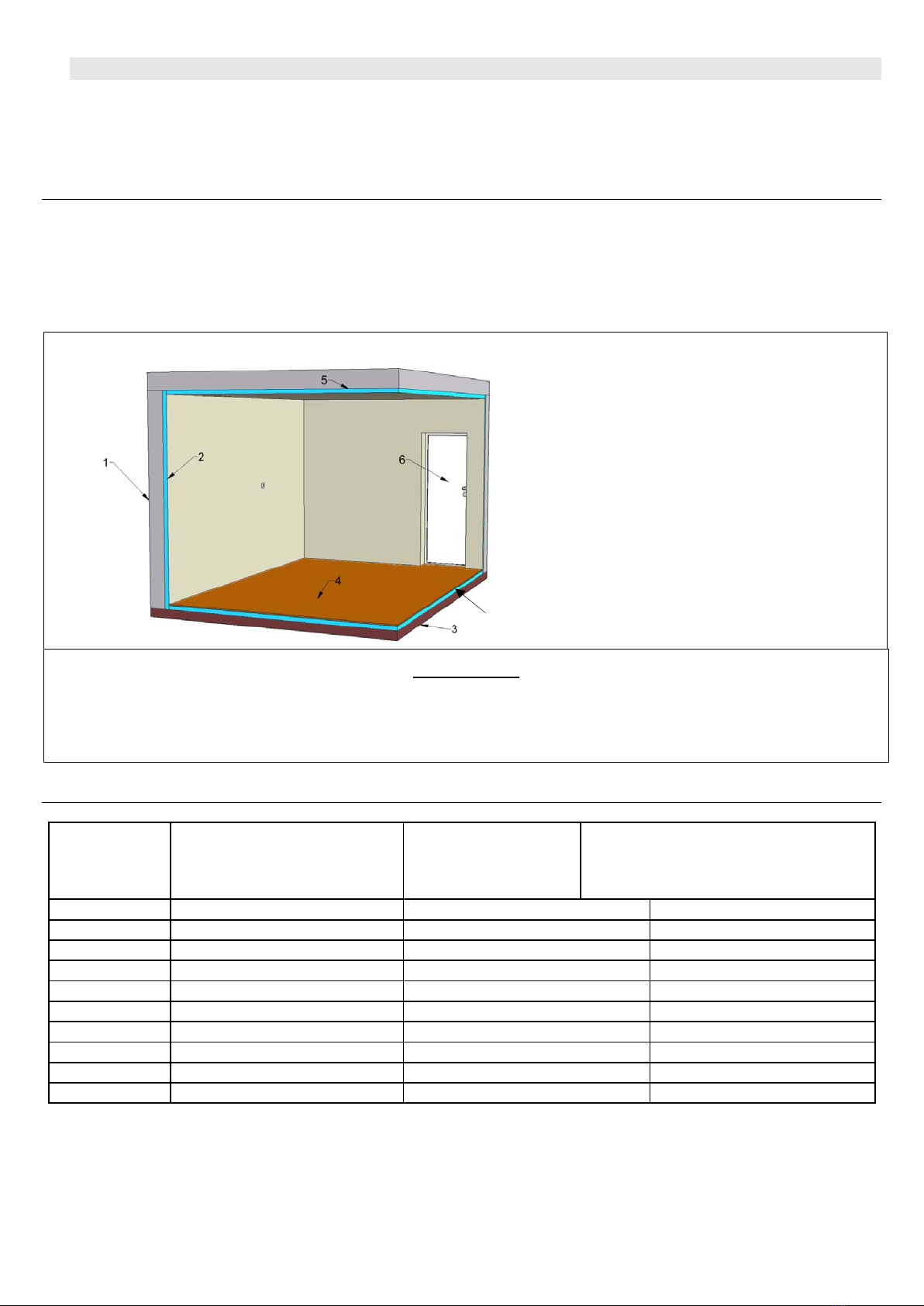

2.6.Cellar insulation......................................................................................... 8

2.6.1.Insulation of walls, ceiling and floor ................................................................................9

2.6.2.The door ......................................................................................................................9

2.6.3.Insulation of other elements...........................................................................................9

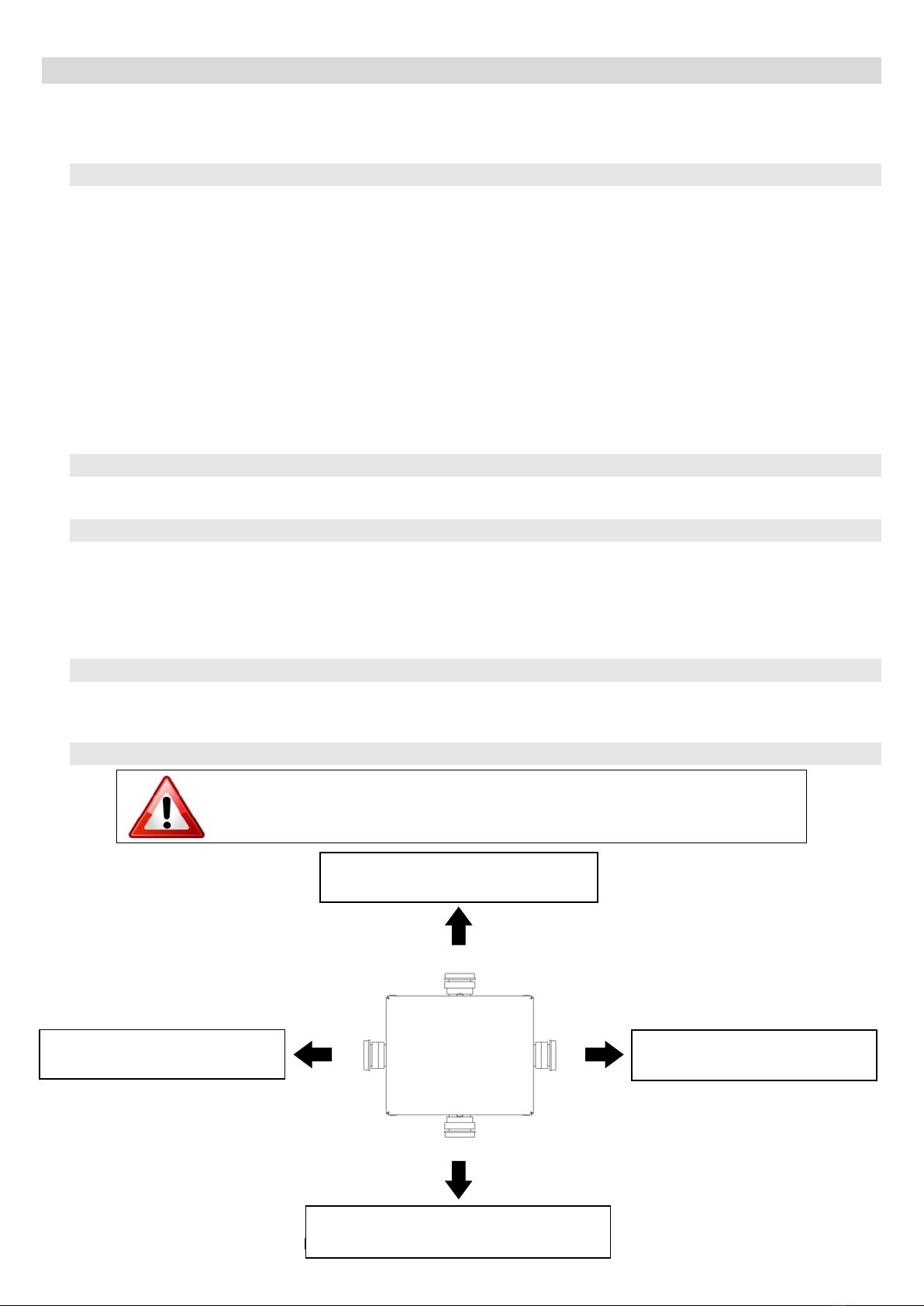

3.INSTALLATION OF THE AIR CONDITIONER WINEMASTER®.....................10

3.1.List of required material ..............................................................................10

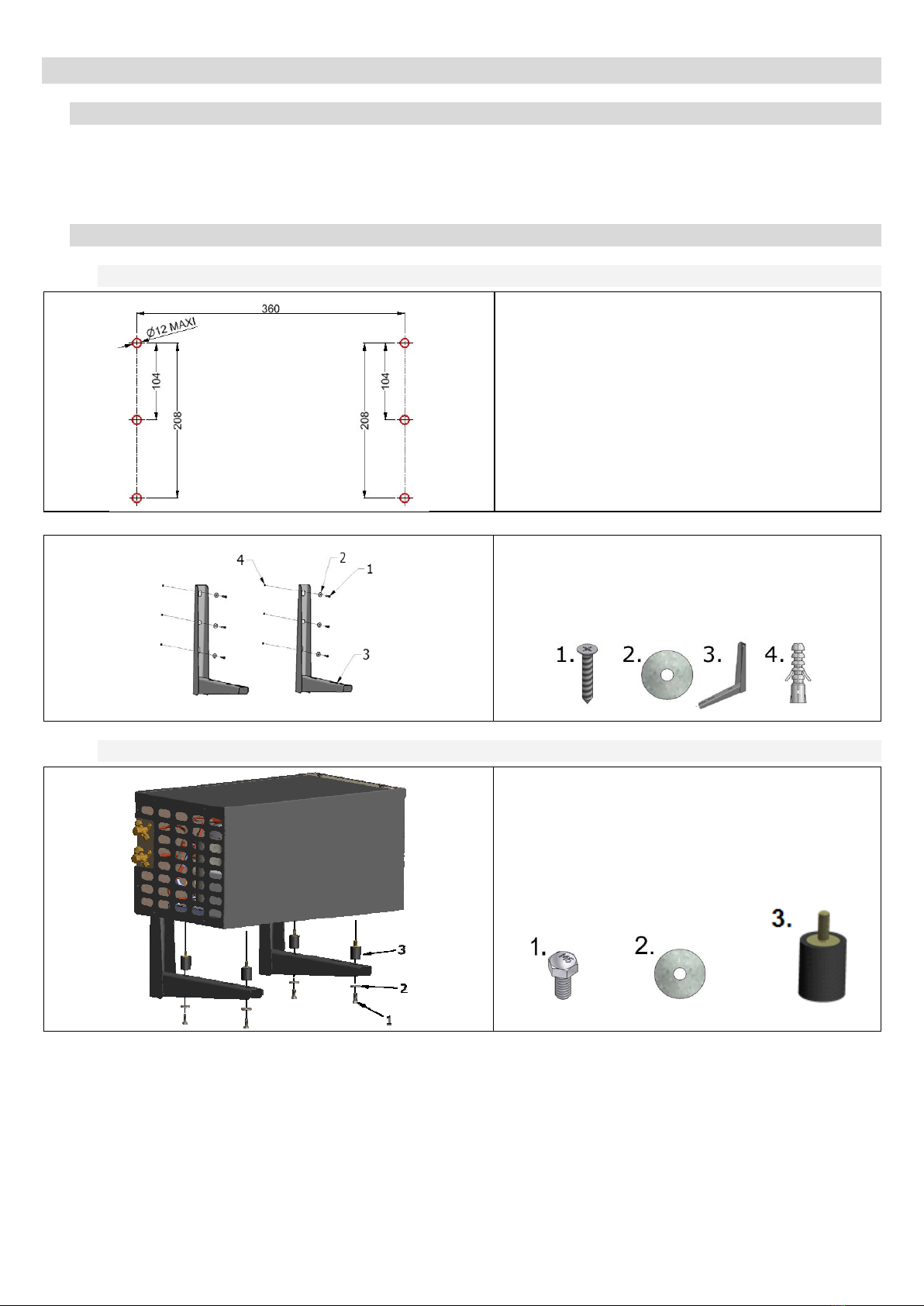

3.2.Installation of the outside unit .....................................................................10

3.2.1.Brackets installation ....................................................................................................10

3.2.2.Fixing the outside unit .................................................................................................10

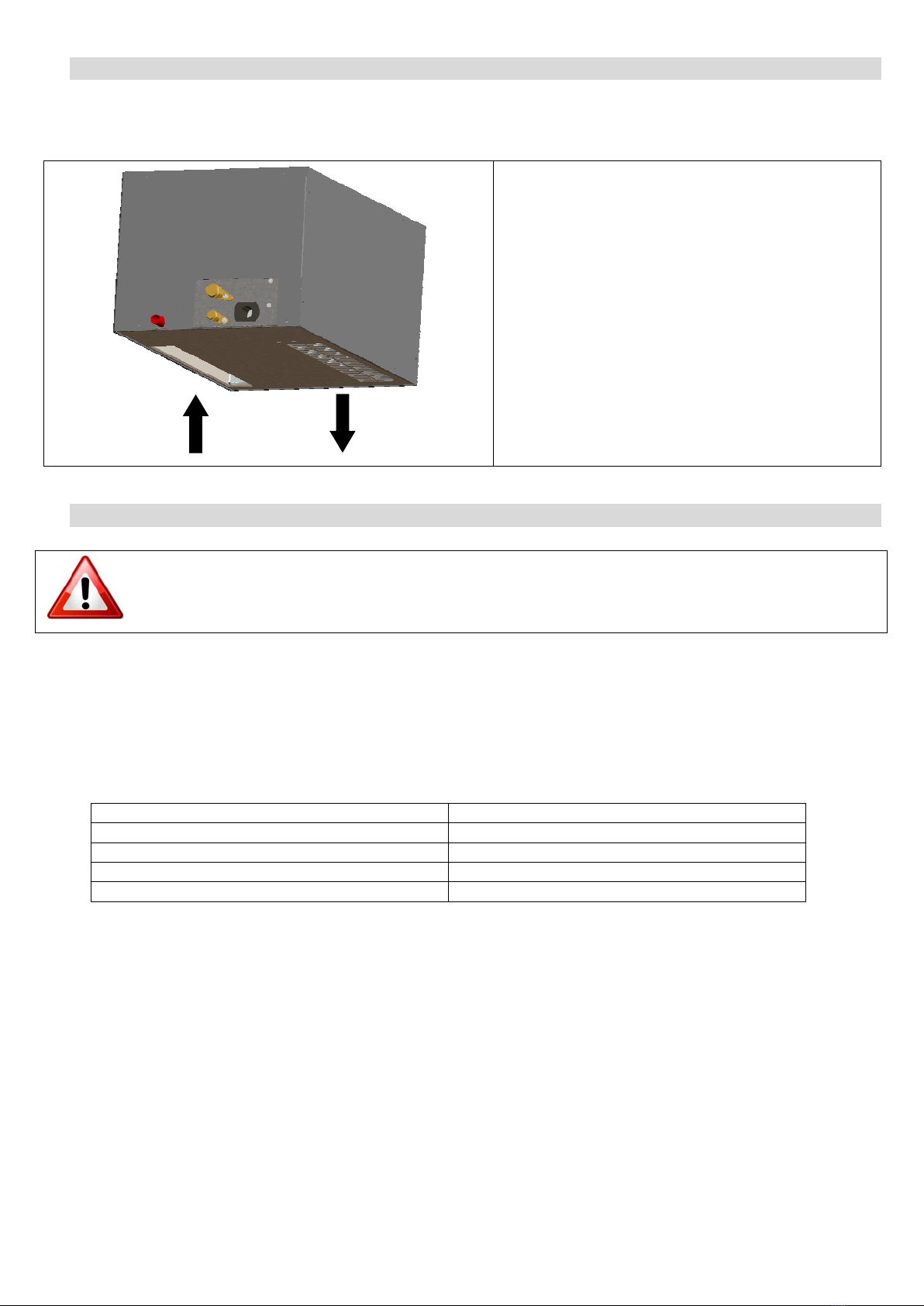

3.3.Installation of the inside unit .......................................................................11

3.4.Ducting connection .....................................................................................11

3.5.Electric connection .....................................................................................12

3.5.1.Connection of outside unit............................................................................................12

3.5.2.Connection of inside unit..............................................................................................12

3.5.3.Plugging.....................................................................................................................12

3.5.4.Wiring drawing ...........................................................................................................13

3.6.Installation of the water drain system ...........................................................14

4.PLUGGING THE AIR CONDITIONER WINEMASTER®.................................14

4.1.Connecting the air conditioner .....................................................................14

4.2.Start up ....................................................................................................15

4.2.1.Temperature setting ....................................................................................................15

4.2.2.Standby mode ............................................................................................................15

4.2.3.Automatic defrost........................................................................................................15

5.MAINTENANCE OF THE AIR CONDITIONER WINEMASTER®.....................16

5.1.Filter and outside unit cleaning ....................................................................16

5.2.Condensates drain......................................................................................16

6.WARRANTY..............................................................................................17

6.1.Legal warranty...........................................................................................17

6.2.2 years contractual warranty .......................................................................17

6.3.Warranty conditions....................................................................................17

6.4.Exclusions and limitations of warranty ..........................................................17

GB