Yantai Winmore Trade Co., Ltd. www.winmoreltd.com

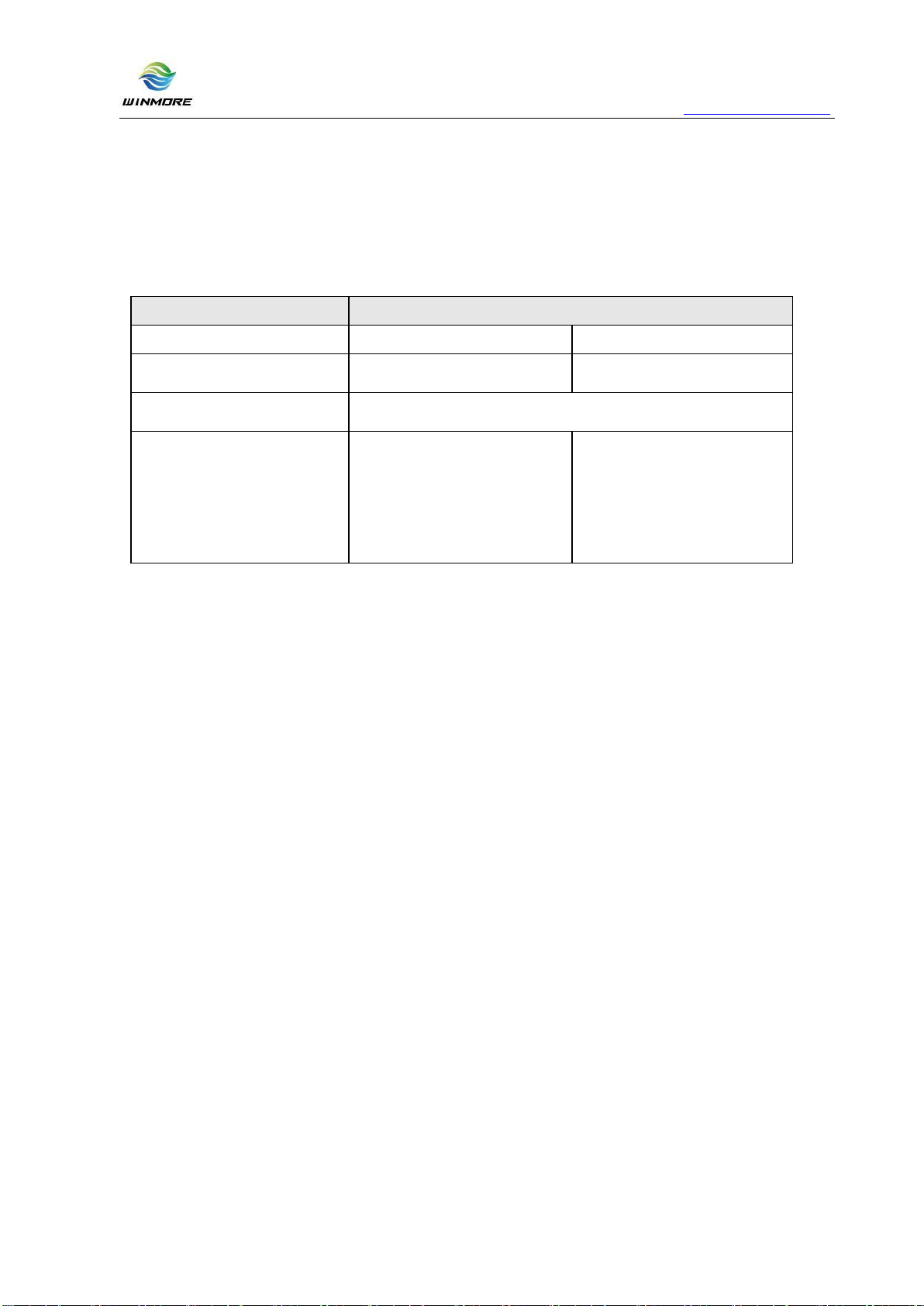

3. Maintenance Schedule and Method

3.1 Maintenance Schedule

Although W551-B/C is equipped with a self-cleaning brush as standard, but bad working

conditions will still cause the sensor to be contaminated. In order to ensure accurate measurement,

cleaning is very important. Regular cleaning of the sensor is helpful to the stability of the data.

Recommended maintenance frequency

It is recommended to clean

once every 3~4 weeks

It is recommended to clean

once every 2~3 weeks

According to working conditions and user needs, but no later

than once every 3 months

Maintain and check the self-

cleaning brush

Replace with a new brush

every 3~6 months (depending

on the specific working

conditions);

return to the factory to replace

the dynamic seal every 18

months

Replace with a new brush

every 2 months (depending on

the specific working

conditions);

return to the factory to replace

the dynamic seal every 18

months

3.2 Maintenance Method

1. Sensor outer surface cleaning: clean the outer surface of the sensor with tap water. If there are still debris

remaining, wipe it with a moist soft cloth. For some stubborn dirt, you can add some household detergent to

the tap water to clean.

2. Sensor measuring window surface clean: use a fine-bristle brush or a fine cotton swab to scrub the light

window, avoid scratching with sharp objects, so as not to scratch the light window.

3. Check the sensor cable: the cable should not be taut during normal operation, otherwise the internal wires

of the cable may be broken for a long time, causing the sensor to work abnormally.

4. Check the cleaning brush: check whether the brush is in effective contact with the light window, whether

it rotates normally, and whether it is loose; if the brush is severely worn and cannot scratch the window

surface, it needs to be replaced, if the brush is loose, it needs to be re-tightened.

5. Continuous use for 18 months, need to return to the factory to replace the dynamic sealing device.

▲Precautions

1. The sensor contains sensitive optical components and electronic components. Make sure that the sensor is

not subject to mechanical shocks. There are no parts inside the sensor that need user maintenance.

2. The sensor self-cleaning brush has a geared motor inside. Under no circumstances should the cleaning

brush be rotated by external force (except for the operation of replacing the cleaning brush against the

wall), or obstruct the rotation of the cleaning brush. Larger external force factors can cause damage to

the geared motor.