Customer Care | 800.234.5286

| +1.502.495.5400 |

winstonfoodservice.com

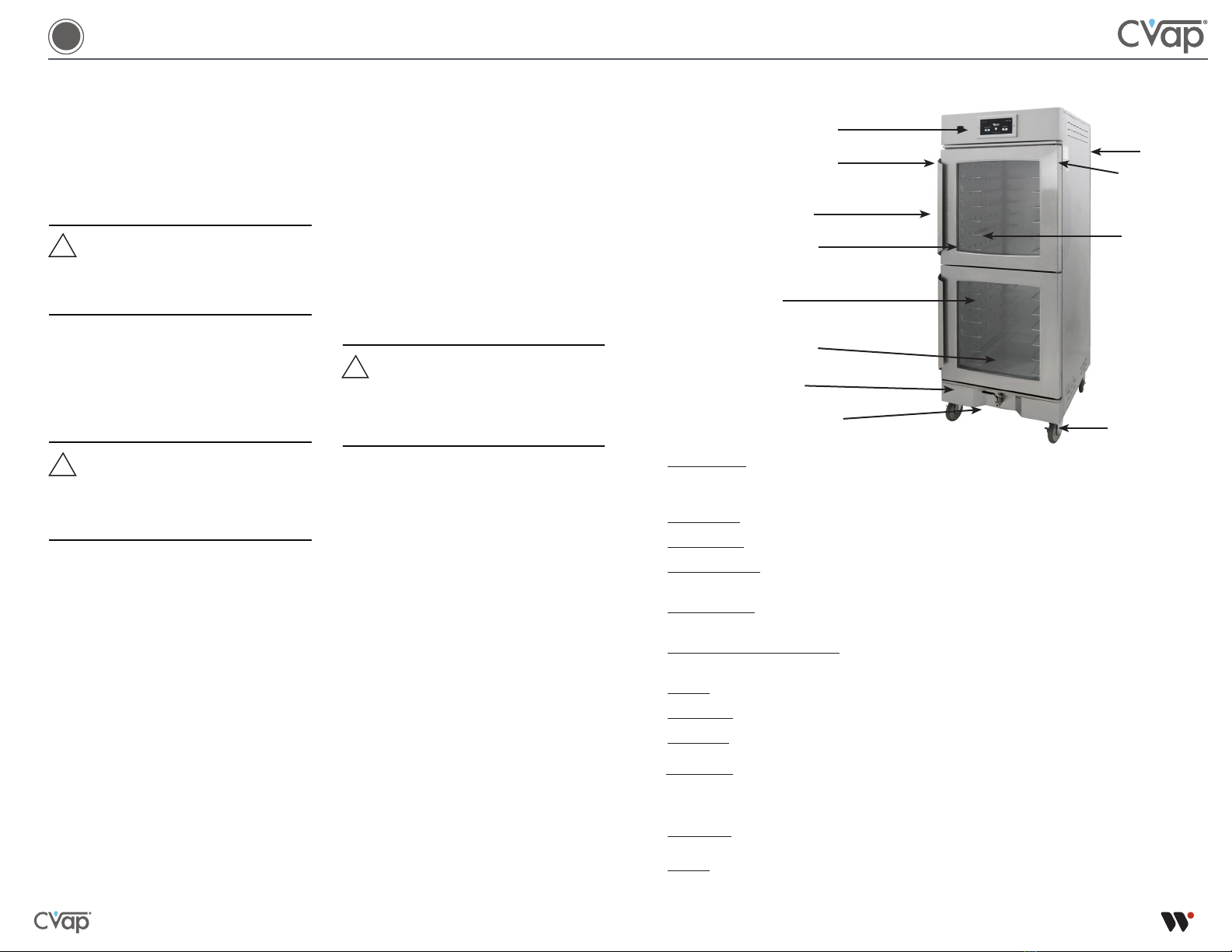

equipment type - class series 3

3

Requirements

GENERAL INSTALLATION

Install equipment on a solid, flat, level

surface in a location where ambient

temperatures will not exceed 100 F and

away from grease laden vapors from other

equipment. For proper ventilation of the

equipment, allow 2-inch clearance on all

sides, particularly around any ventilation

holes. Plug the equipment into a properly

grounded outlet of the correct voltage and

phasing as indicated by the equipment ID

labels. Please read the installation instructions

that follow.

water

If manually filling equipment with water, fill

evaporator pan with approximately 2.5

gallons of water.As water evaporates,

minerals in the water will deposit on the

surface of the evaporator. These mineral

deposits will inhibit the transfer of heat.

Deposits can also degrade and damage

stainless steel. To avoid mineral deposits

clean the equipment daily. It is advisable to

contact your water utility for advice on

minimizing deposit buildup.

!CAUTION:CAUTION:

High Temperature Hazard

Can cause damage to equipment >>

If utilizing vapor heat, ll evaporator with

water prior to turning power on and do not

allow evaporator to run dry.

Do not place equipment in an area where

ambient temperature (air temperature

around the equipment) exceeds 100° F

(38° C). A heat shield may be required to

prevent excessive heat exposure and grease-

laden vapors from affecting the equipment

if adjacent to heat, vapor, or grease

generating devices (such as grills, steamers,

ovens, etc.). Excess heat and grease inside

the equipment cavities may cause electrical

components to fail.

Vent Hood: Generally this equipment does

not need to be installed under a mechanical

ventilation system (vent hood). Check local

health and fire codes for requirements

specific to your location.

auto water fill

Automatic water fill is available as an

optional feature. Auto water fill systems

must be hooked up to a potable water

supply line. The maximum incoming water

temperature may not exceed 140 ˚F (60 ˚C)

and the incoming water pressure must be

between 20 and 150 psi (137.9 kPa to 1034

kPa). Equipment with auto water fill systems

MUST NOT BE ALLOWED TO RUN DRY. Heat

damage to the water valve may result.

It is the responsibility of the owner and

installer to ensure that installation complies

with all local and state plumbing codes.

shelving

The load limit per rack is 65 lbs (29.25kg).

Internet: https://foodservice.winstonind.com/

Phone: 800.234.5286 | +1.502.495.5400

Fax: +1.502.495.5458

Mail: 2345 Carton Drive | Louisville, KY 40299 USA

Contact Information

For locations with hard water, add one

tablespoon (15 ml) of white vinegar or

lemon juice to water to help minimize scale

buildup. Please consider contacting your

local water authority to obtain advice on

possible water treatments to protect the

equipment. Some water supplies are high

enough in chemical content to be capable

of damaging stainless steel (if used

untreated). The evaporation process can

concentrate the chemicals in the water to a

level which could cause a damaging

reaction with the stainless steel.

ventilation

Ventilation Clearances: To operate properly,

the equipment will need sufficient space for

air circulation. Allow at least 2" (51 mm)

clearance on all sides, particularly around

ventilation holes. Care should be taken to

prevent placing the equipment close to

anything combustible. It must be installed

with its supplied casters or legs. Equipment

may be stacked upon each other using only

a Winston supplied stacking kit and

following the instructions enclosed with the

kit. Your warranty may be void if you do not

adhere to these ventilation requirements.

!CAUTION:CAUTION:

High Temperature & Grease Hazard

Can cause damage to equipment >>

Avoid placing equipment near high heat or in

grease-laden atmosphere.