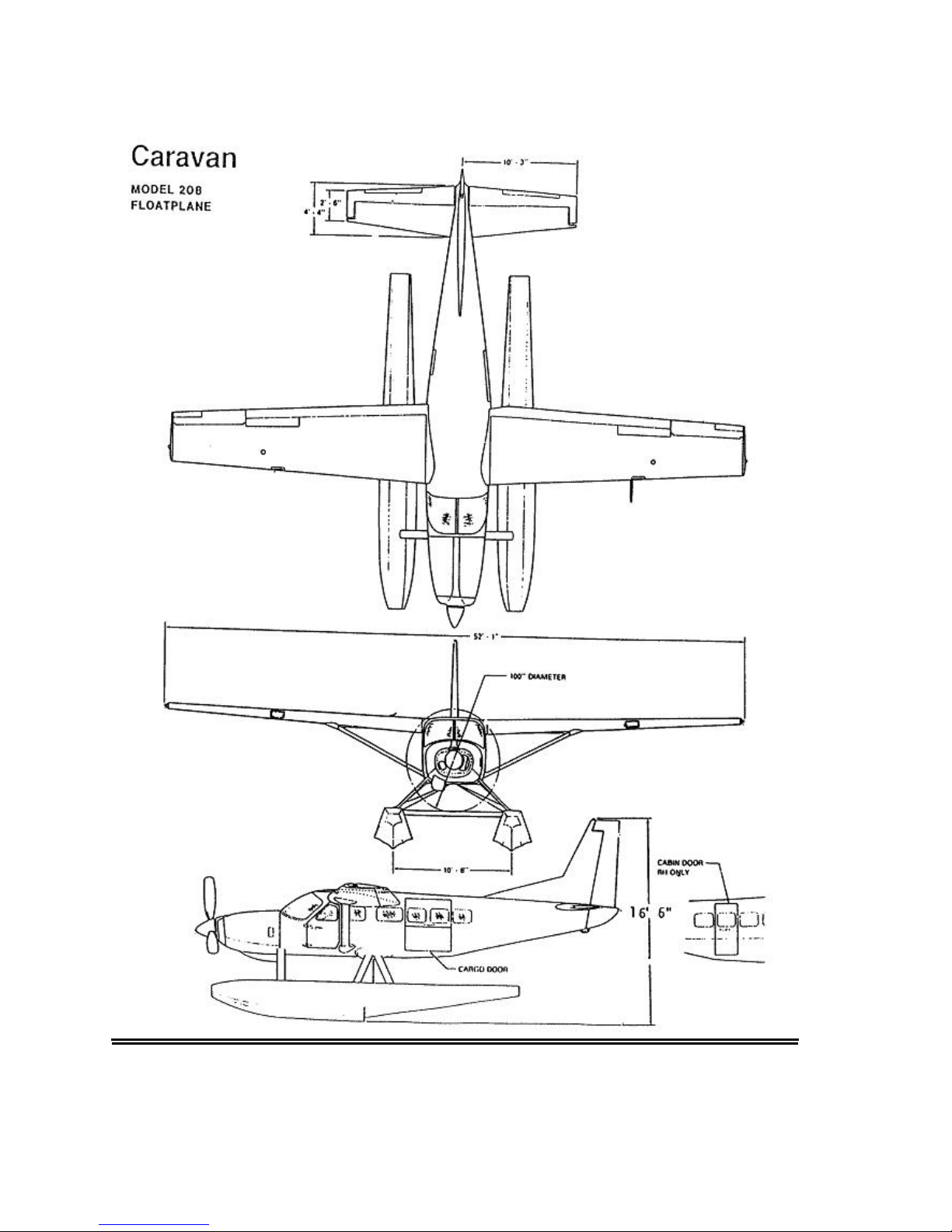

WIPLINE MODEL 8000 SERVICE MANUAL

1002554 • Rev HPage 3of 62

TABLE OF CONTENTS

SECTION PAGE

LOG OF REVISIONS................................................................................................................. 5

NEW CUSTOMER INFORMATION ........................................................................................... 6

1.0 GENERAL...........................................................................................................................11

2.0 FLOAT HULL MAINTENANCE............................................................................................12

2.1 GENERAL.......................................................................................................................12

3.0 FLOAT HANDLING, JACKING, AND AIRCRAFT TOWING ...............................................15

4.0 AMPHIBIAN LANDING GEAR SYSTEM OPERATION & MAINTENANCE .........................16

4.1 LANDING GEAR HANDLE..............................................................................................16

4.2 INDICATOR LIGHTS.......................................................................................................16

4.3 LANDING GEAR OPERATION........................................................................................17

4.4 EMERGENCY PUMP HANDLE.......................................................................................17

5.0 MAIN AND NOSE GEAR OPERATION, REMOVAL AND SERVICE..................................18

5.1 DESCRIPTION AND OPERATION..................................................................................18

5.1.1 SERVICE – NOSE GEAR .........................................................................................19

5.1.2 SERVICE – MAIN WHEELS AND BRAKES..............................................................19

5.1.3 SERVICE – MAIN GEAR OLEO................................................................................19

5.2 ADJUSTMENT/TEST ......................................................................................................21

5.2.1 NOSE GEAR.............................................................................................................21

5.2.2 NOSE BOX TRACK WEAR.......................................................................................21

5.2.3 SERVICE – MAIN GEAR RETRACTION SYSTEM...................................................21

5.2.4 BLEEDING HYDRAULIC SYSTEM AFTER SERVICE..............................................22

5.3 MAIN AND NOSE GEAR REMOVAL AND DISASSEMBLY ............................................23

5.3.1 REMOVAL OF MAIN GEAR OLEO...........................................................................23

5.3.2 REMOVAL OF MAIN GEAR RETRACTION CYLINDER...........................................28

5.3.3 REMOVAL OF MAIN GEAR DRAG LINK..................................................................28

5.3.4 REMOVAL OF NOSE GEAR FROM NOSE BOX......................................................28

5.3.5 REMOVAL OF NOSE GEAR BOX............................................................................29

5.3.6 REMOVAL OF LOWER NOSE GEAR FROM PIVOT BLOCK...................................29

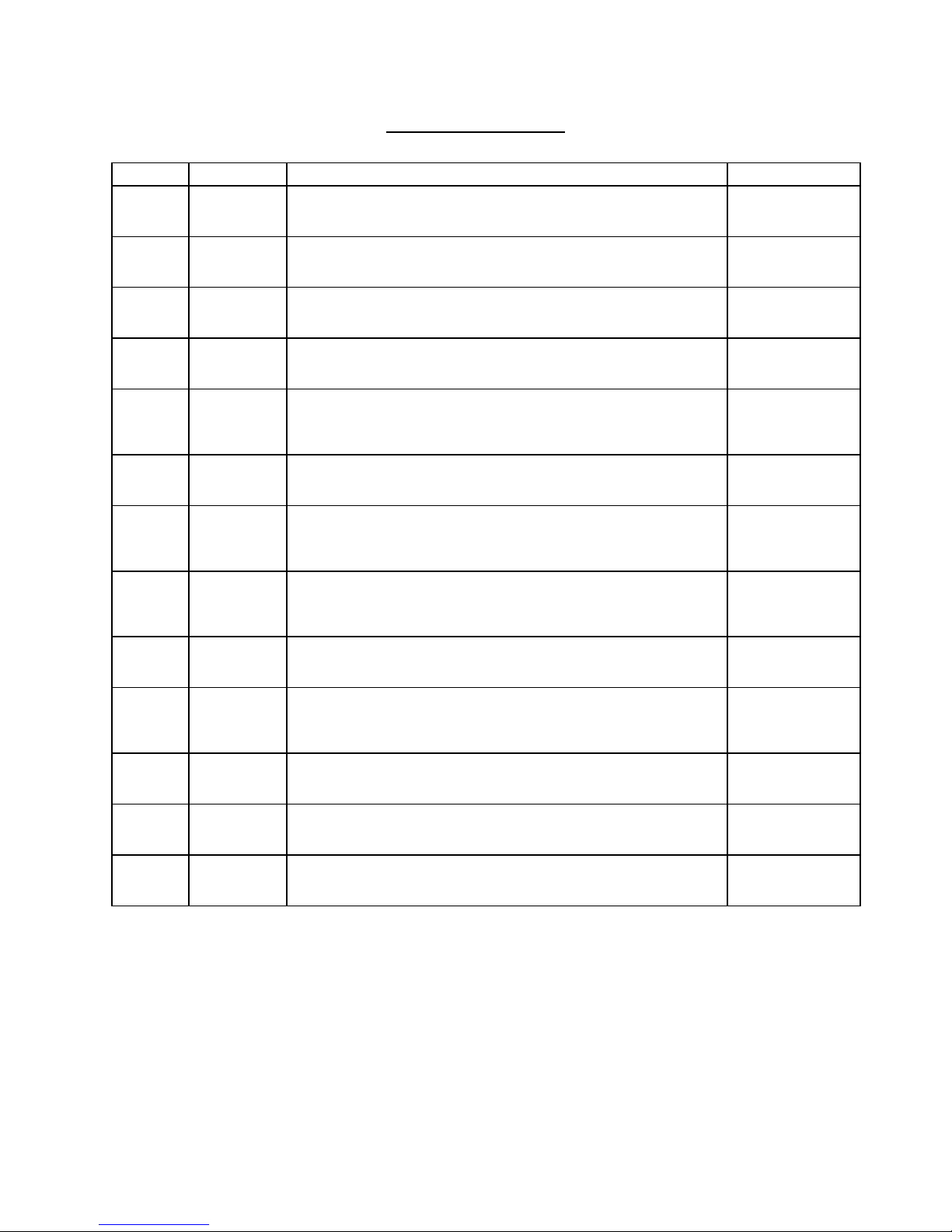

5.4 SERVICE SCHEDULE ....................................................................................................29

5.5 HYDRAULIC PUMP SYSTEM, DISASSEMBLY AND SERVICE .....................................32

5.6 INSPECTION TIME LIMITS AND CHECKLIST................................................................33

5.7 CESSNA FLOAT REMOVAL INSTRUCTIONS / PROCEDURES....................................37

5.8 CESSNA FLOAT RE-INSTALLATION INSTRUCTIONS / PROCEDURES......................40