6

SFBTT15 BobTail® Hydraulic Installation Tool (HK1151)

Preparation for Use

®

Pressure Settings

Threadmate is a registered trademark of Parker Intangibles LLC.

Loctite is a registered trademark of Henkel Corporation, U.S.A.

Slic-tite is a registered trademark of LA-CO Industries, Inc.

WARNINGS:

Read this entire manual before using tool.

recommended before using Huck equipment.

When operating Huck equipment, always wear approved eye

and hearing protection.

Be sure there is adequate clearance for the operator’s hands

before proceeding.

Use only Huck Powerig® Hydraulic Units as a power source

for Huck installation equipment. Hydraulic power units

that deliver high PULL and RETURN pressures, but are not

not recommended

and may be dangerous.

Connect tool hydraulic hoses to the Powerig before

connecting tool switch control cord to the unit. If not

connected in this order, severe personal Injury may occur.

Correct PULL and RETURN pressures are required for

operator safety and installation tool function. Gauge

T-124833CE is available for checking pressures. See

and Gauge Instruction Manual. Failure to verify

pressures may result in severe personal injury.

CAUTIONS:

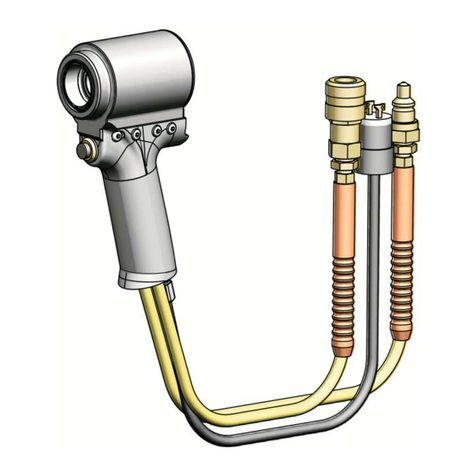

Apply Parker Threadmate®,

Loctite® 567, or Slic-Tite®

to male pipe threads (per

manufacturer’s instructions)

to prevent leaks and to ease

assembly.

Keep disconnected hoses,

away from dirty surfaces

and free of foreign matter.

cause tool and Powerig valve

failures.

Hose couplers must be

completely joined in order

to ensure that ball checks in

the nipple and the body are

completely open. Improperly

assembled couplers will cause

overheating and malfunctions

in tool and Powerig. Hand

tighten couplers; do NOT use

a pipe wrench.

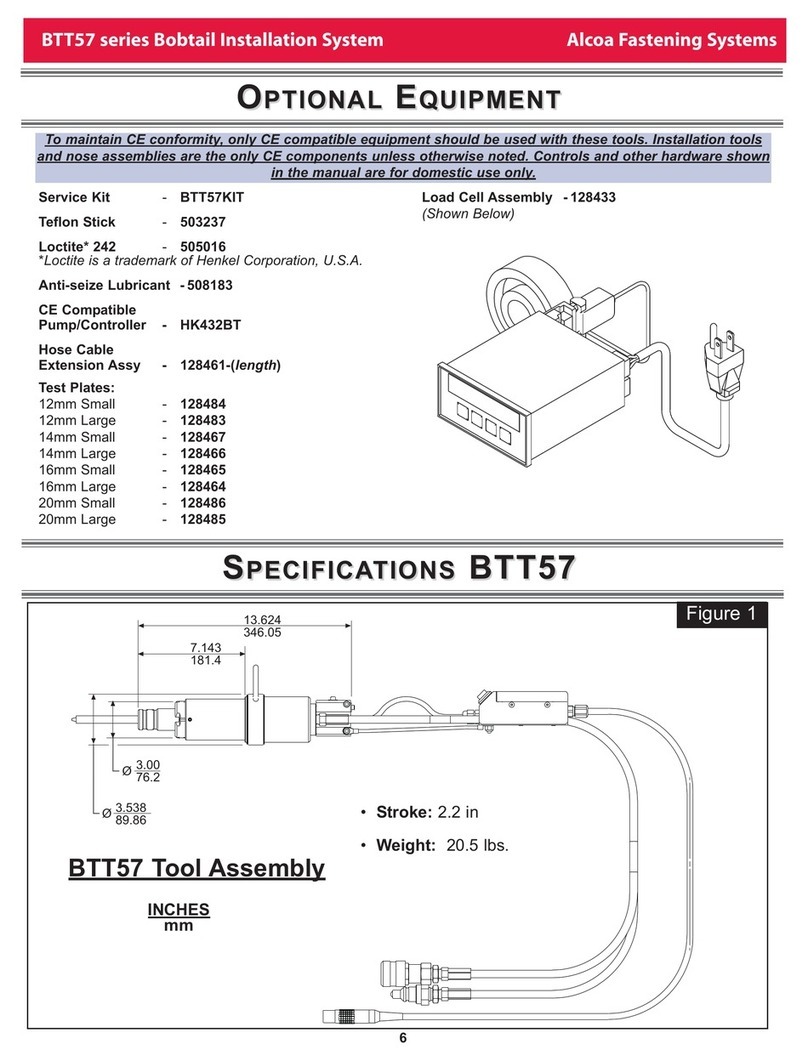

Fastener

Size

Fastener

Grade

Powerig PULL

Pressure Setting

Powerig RETURN

Pressure Setting

5(269 bar) (117 bar)

8(386 bar) (165 bar)

Assembly of NPTF Threaded Components

AIR FITTINGS

®

HYDRAULIC FITTINGS

™

ALL FITTINGS:

Thread Size Final thread engagement at full

make-up

1/8-27 NPTF .235 inch (.59 cm)

1/4-18 NPTF .339 inch (.86 cm)

3/8-18 NPTF .351 inch (.89 cm)